As one of the biggest 3D printing events of the year, last week’s RAPID + TCT conference created the busiest news week of 2019 so far.

Reporting live from the show, backed by a team covering all of the latest press releases from the event, 3D Printing Industry provided leading coverage of North America’s must-see show. Between May 20 and 24, around 80% of all articles published by us contained RAPID related news.

In case you missed it, here we have a roundup of the releases made at RAPID + TCT 2019, including new 3D printers from Titan Robotics, Tethon and BigRep, Origin’s emergence from stealth mode, the latest software releases, materials and post processing solutions.

Up to speed with 3D printing in automotive

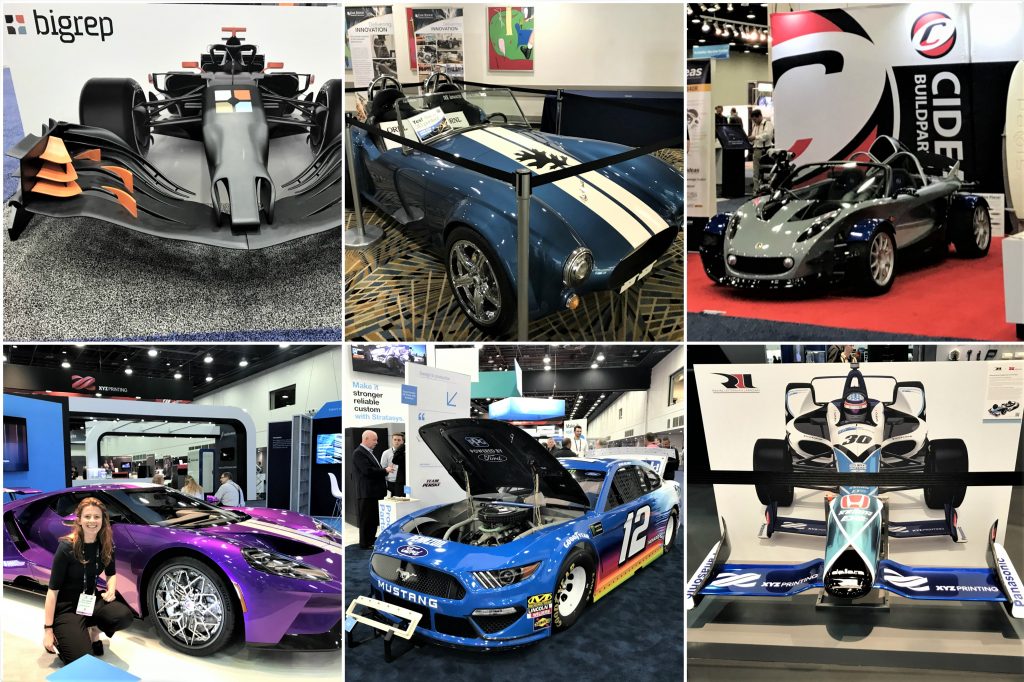

Keeping with the automotive legacy of Michigan’s Motor City and the specialist conference track set up by SME, many of the applications showcased by companies at RAPID + TCT highlighted the competitive advantage in motorsport.

American manufacturing service provider Jabil announced a Formula 1 3D printing partnership with the Renault F1 Team, GE Additive presented the latest wheels from HRE, and leading OEM Stratasys confirmed collaboration with IndyCar racing team Arrow Schmidt Peterson Motorsports and leading drag racing company Don Schumacher.

3D printed car parts were also sported by XYZ Printing, BigRep and Brad Keselowski Engineering, Oak Ridge National Laboratory with Detroit-local General Motors providing a dedicated experience zone, with plenty of auto-eye candy on show.

Bottom L-R: Ford GT with wheels 3D printed by GE Additive and HSE, a demo Ford Mustang at Stratasys’ booth, 3D printed prototype F1 car nose by BigRep. All photos by Beau Jackson

Where is the value of additive manufacturing?

As many companies continue to adopt a solutions-based approach to the technology, therefore validating 3D printing’s purpose in the wider manufacturing sphere, applications is certainly where the majority of news continues to take place.

In a special press presentation, Israeli ceramic and metal 3D printer manufacturer XJet revealed how the University of Delaware is using its system to develop 5G antennas, and gave details of Marvel MedTech’s application which it helping to fight breast cancer. Dror Danai, CBO of XJet, also confirmed that the company has already signed customers for the beta testing of metal and ceramic 3D printing in the same machine. The hope is that the XJet will have installation of a new machine made in time for Formnext 2019 in November.

Elsewhere nScrypt was there exhibiting new 3D printed electronics, Ultimaker showcased a production-line collaboration with Heineken, Indo-MIM became a valuable customer of the Dektop Metal Production System, and HP confirmed a dental aligner partnership with SmileDirectClub. In the next 18 months, HP representatives confirmed that they also hope to have partners similar to SmileDirectClub for the developing Metal Jet system.

Latest 3D printer releases

Though machine launched had been more low key in the latter half of 2018, RAPID + TCT actually saw the release of more than ten 3D printers (and some 3D scanners) this year.

Some notable launches from the past week included:

– The public display of Essentium’s High Speed Extrusion 180-S 3D printer

– Impossible Objects’ CBAM-2

– XBeam Electron Beam Melting (EBM) technology from Ukranian manufacturer Chervona Hvilya

– The Prodways Promaker P1000 X

– Shining 3D’s compact EP-M150 metal 3D printer

– 3D Systems Figure 4 Modular

– An industrial Quantum Laser Sintering system, the QLS 350, from California’s NXT Factory

– Origin’s departure from stealth mode with the Origin One

– The 3DQue automated 3D printing system

– BigRep’s Studio G2 3D printer

– For ceramics, the Tethon Bison

– And Titan Robotics‘ Atlas-H large-scale dual extrusion system

In 3D scanning, we have also covered the launch of the Evatronix automatic eviXmatic inspection system.

Does 3D printing need more materials?

Working hard to fulfill the needs of material selection in 3D printing, all of the chemical giants operating within this industry had new products to show in Detroit.

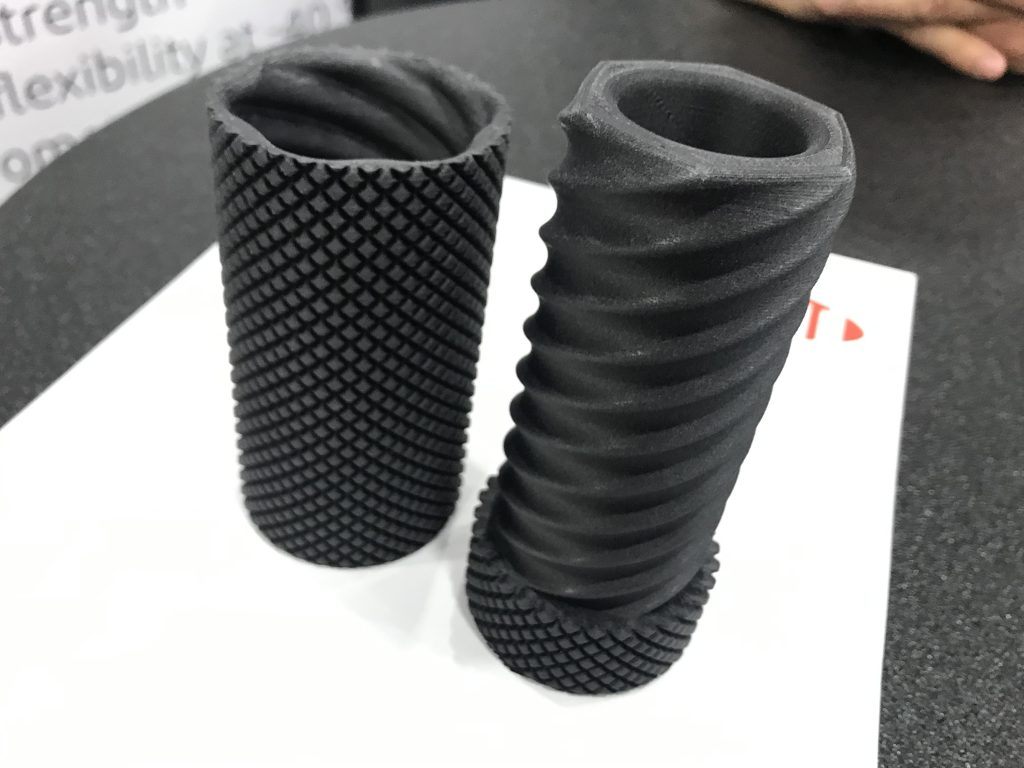

DSM and Adaptive3D introduced the ToughRubber material, German RepRap, Dupont and Dow Chemical showcased high performance materials for 3D printing, BASF signed a partnership to test its materials on the Paxis’ Wave Applied Voxel (WAV) 3D printing platform, (as well as being a launch partner of Origin’s Open Materials Platform), Sandvik launched a diamond composite material as well as inking a metal powder partnership with ExOne, and Stratasys and Solvay committed to developing new polymers.

Californian metal 3D printer manufacturer Formalloy also introduced the Alloy Development Feeder and robotic integration system for its directed energy deposition (DED) technology.

Building secure and repeatable processes with 3D software

As 3D printing matures, software is the supporting factor helping to create more reliable processes and protect files. There are several different ways of achieving these goals, many of which were explored in new releases at RAPID + TCT 2019.

From a file preparation standpoint, Link3D launched the True Shape Nesting feature for SLS and MJF 3D printing.

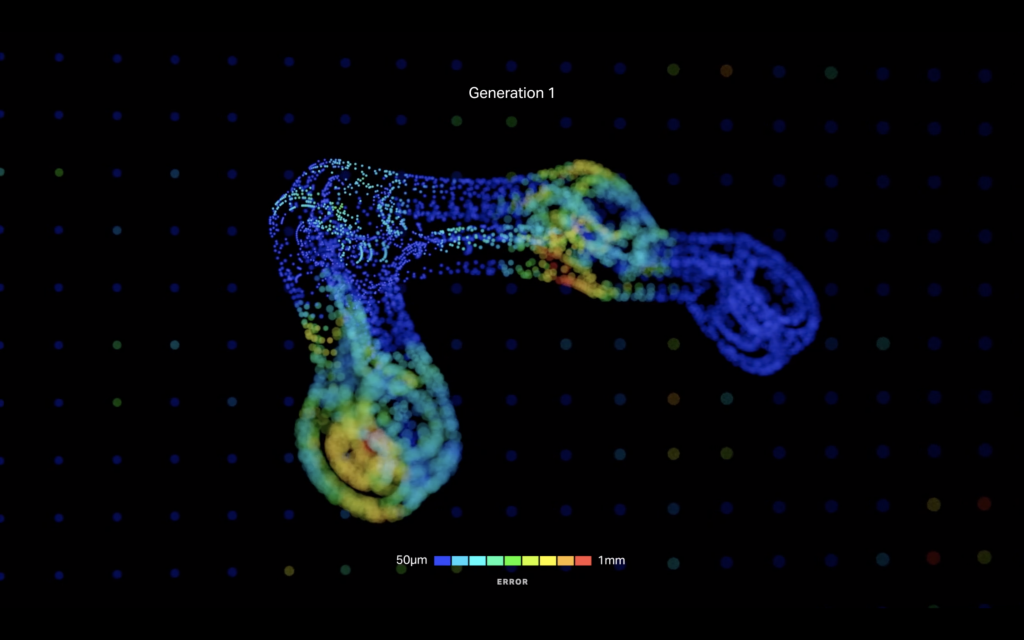

Taking different approaches to “print right first time,” Markforged was showing how artificial intelligence can be applied in its Blacksmith platform and Sigma Labs launched Printrite3D v5.0.

For end-to-end security of the 3D printing process,

Identify3D and Renishaw showed how to protect the IP of metal additive.

Leading Belgian 3D software provider Materialise also announced several new initiatives with HP, Essentium and Nikon.

New post processing solutions

Speaking with a handful of the show’s attendees, post processing was the one area that they hoped to see more of at future trade shows. In Detroit, British company AMT demonstrated its first system PostPro3D, and the PostProcess Technologies team from New York were keen to show the FORTI support removal unit.

Expanding its post-coloring offering, DyeMansion released the ColorsX Automotive and Neon ranges.

In other news…

If you have been following our coverage of RAPID + TCT 2019 you will also have read some of our observations from the show floor and the theme of keynote presentations which set the tone for each day of the event. As part of our time at the Cobo Center in Detroit we were privileged to witness talks by Fast Company’s Bill Taylor, Professor Emanuel “Ely” Sachs, co-founder and co-CTO of Desktop Metal, Todd Grimm, Stryker’s Director of Advance Operations, Additive Technology Solution Dr. Naomi Murray and many others.

Outside of the keynotes, and main stage presentations, events taking place throughout RAPID + TCT 2019 included America Makes’ Game Day experience, as well as an in depth panel considering certification from Women in 3D Printing representatives Tracy Albers (rp+m), Ellen Lee (Ford Motor Co.), Dr. Amy Alexander (Mayo Clinic), Jennifer Fielding (ARL) and Barbara Hanna (Cyant).

For more of 3D Printing Industry’s leading events coverage and exclusive interviews still to come, subscribe to our newsletter and follow us on Twitter.

Stay tuned for the announcement of this year’s 2019 3D Printing Industry Awards winners and check out 3D Printing Jobs for new opportunities in your sector.

Featured image shows the entrance to RAPID + TCT 2019 in Detroit’s Cobo Center. Clip by Beau Jackson