3DQue, a 3D printing startup based in Vancouver, is showcasing a new automation system and software for desktop FFF/FDM 3D printing at RAPID + TCT this week.

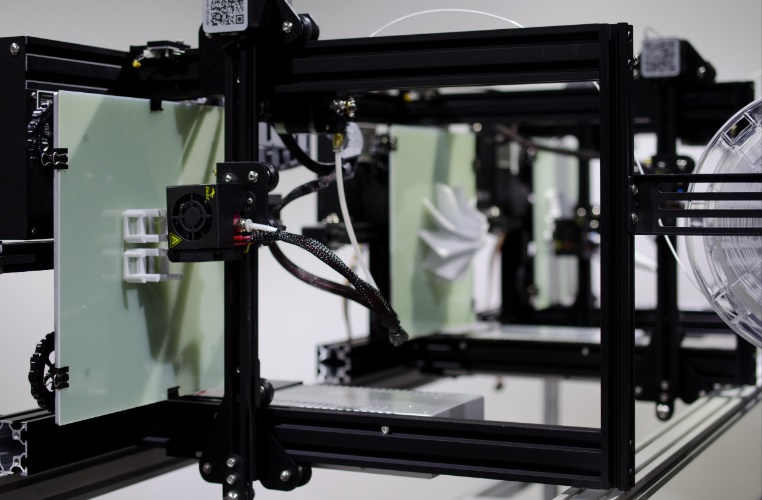

The QPoD is a high-volume production unit with nine 3D printers in a compact 3×3 array with a total footprint of 10 sqft. This system enables the management of varying filaments and nozzles. It is driven by the company’s automation technology QSuite, which allows for 24/7 remote control of all 3D printers and jobs, including scheduling and monitoring, for mass production of parts.

“Until now, plastic 3D printing failed to meet today’s manufacturing needs due to the high cost of part removal and lack of scalability,” said Steph Sharp, CEO and co-founder of 3DQue.

“Working from his basement, Mateo Pekic has been able to solve a problem that has stumped some of the world’s leading experts in materials science, engineering and innovation by automating plastic 3D printers to safely produce complex plastic parts at scale.”

Automating FFF

Mateo Pekic, the 18-year-old co-founder of 3DQue, established the company last year after wanting to go beyond prototyping to make small quantities of parts. According to Pekic, 3D printing such amounts is time-consuming as they must be manually removed before the next print could begin.

Inspired by industrial automation, Pekic developed a way to remove parts and start in a more efficient way. As a result, the QPoD delivers parts, resets the 3D printers and starts the next print job while parts are transported on a built-in conveyor system to a collection bin, ready for the next step in the production. This system has been running Pekic’s 3D printers with full automation for over 2 years.

24/7 FFF 3D printing

3DQue’s QSuite’s automated part removal technology is integrated into the QPoD in order to eliminate the need for manual tasks such as part removal, print bed

reset, and restart. QSuite is said to use a proprietary suite of hardware and software technologies, to mass produce 3D printed parts.

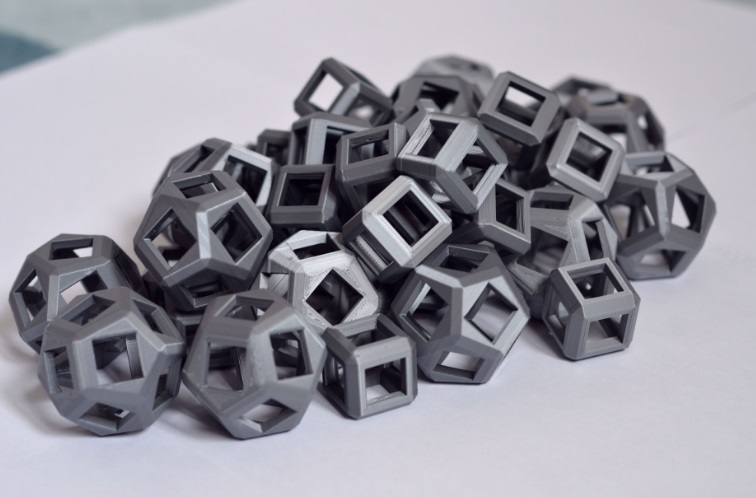

This process includes reprioritizing jobs based on changing deadlines or parts, as well as user control through real-time reporting and management data. Earlier this year, the company conducted a field trial conducted using the QPoD. The system was able to produce switch cube frames (25x25x25mm – 2.7 grams) at a rate equivalent to 100,000 parts per year. This translated to a production capacity of more than 8,000 parts/sqft.

Pre-production units of the QPod powered by QSuite are currently available at a cost of $45,000. This consists of on-site installation of one QPoD; a 5-year QPoD

equipment lease; 3,000 print-hours of QSuite software; and 18 months of QSuite software support.

Those interested in QSuite itself can apply for a license from September 2019. Both the QPoD and QSuite will be demonstrated at RAPID + TCT at booth 1765.

Don’t forget to vote for the 2019 3D Printing Industry Awards.

Also, subscribe to our 3D Printing Industry newsletter and follow us Facebook and Twitter for full coverage of RAPID + TCT.

Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

Featured image shows 3D printed switch cube frames. Photo via 3DQue.