Origin, a California-based startup focused on bringing mass manufacturing to the additive industry, has introduced its Origin One 3D printer.

The Origin One is an SLA/DLP machine which uses a combination of materials, hardware, and software to make high volume 3D printing possible.

With the introduction of its new system, Origin has also partnered with ECCO, one of the largest shoe manufacturers in Denmark.

Jakob Møller Hansen, Vice President Research & Development at ECCO, said, “We expect Origin’s open additive approach will enable us to reduce development time, lower costs, and accelerate our time-to-market.”

High volume 3D printing

Origin was founded in 2015 by Christopher Prucha and Joel Ong to provide 3D printing services to their customers using only open source equipment. At the beginning of its operation, Origin produced NFC tags to authenticate original sneakers manufactured by Beast Mode, a brand founded by American football player Marshawn Lynch.

The founders of Origin encountered many difficulties while producing large quantities of parts with 3D printers. This forced them to find lateral solutions. One such victory was achieved by using Autodesk’s SLA open source 3D printer Ember. With some modifications to the machine’s hardware and software, Origin was successful in producing parts in high volume.

Using this experience, Origin has developed its own system based on programmable photopolymerization (P3). With a build volume of 192 x 108 x 350 mm, the system uses open materials, modular hardware, and specialized software to automate the process. The ease of the system allows one operator to manage several machines for high volume production. Origin calls its new approach to additive manufacturing, Open Additive Production.

The Origin system hopes to differentiate itself via the use of open materials which according to the company will let customers explore the full potential of 3D printing.

Open materials additive manufacturing

Origin is now also working with ECCO to find an innovative way to manufacture shoes. ECCO has already ventured in the 3D printing market with the help of Dow Chemical Company which provided proprietary silicone to ECCO.

As Origin believes open materials are a key to unlock 3D printing mass manufacturing, the company has also partnered with the world’s largest chemical producer BASF, who is creating a new line of photopolymers for Origin’s system.

Furthermore, Origin is also working with the Dutch materials multinational, DSM, to develop materials for open additive manufacturing.

Origin will exhibit its innovative 3D printing platform from May 21-23 at RAPID + TCT in Detroit, booth 2153.

2019 3D Printing Awards are almost here. Vote now for the enterprise 3D printer of the year (Polymers).

3D Printing Industry is in Detroit, bringing you all the latest from Rapid + TCT, subscribe to our 3D printing newsletter and join us for live updates on Facebook and Twitter.

Visit our 3D Printing Jobs page to see who is hiring.

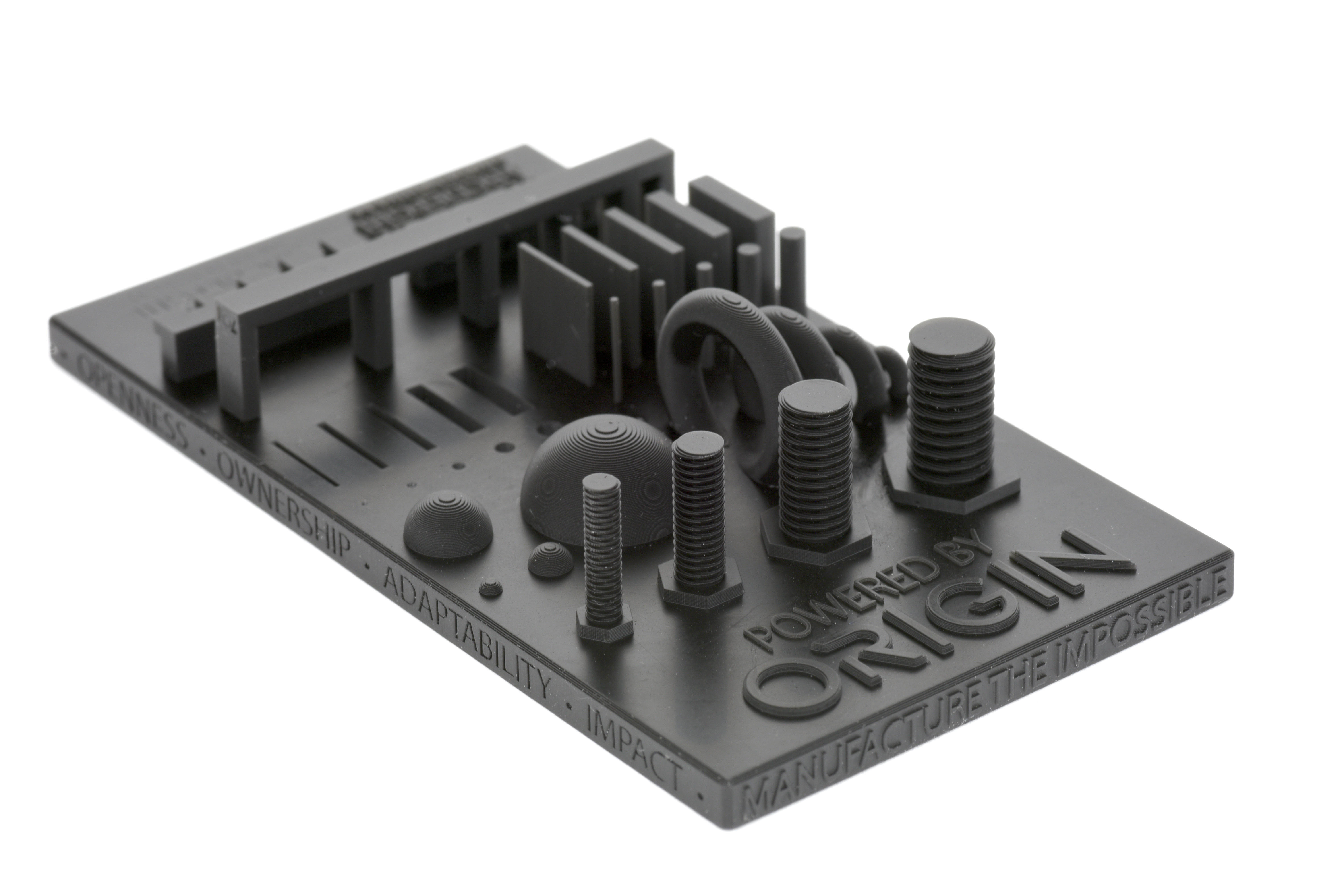

Featured image shows the Origin One 3D printer. Image via Origin.