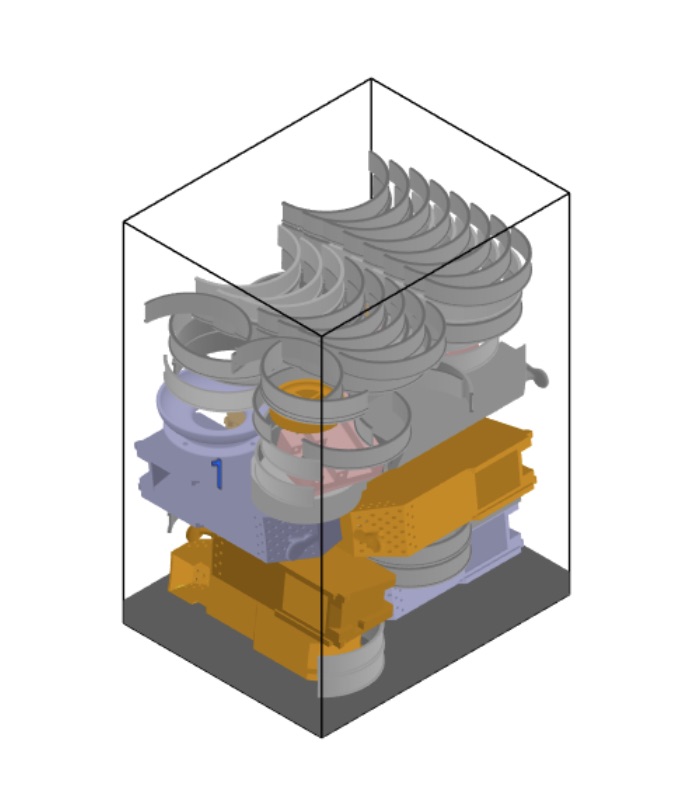

Link3D, a New York-based additive manufacturing workflow software company, has launched a new enhancement to its suite, True Shape Nesting, at RAPID + TCT.

This feature enables Multi Jet Fusion and Selective Laser Sintering (SLS) technologies to find an optimal nesting strategy based on the shape of the 3D model. As such, manufacturers can utilize any orientation for parts, including the Z-axis. Shane Fox, CEO of Link3D, said:

“As a team, which understands what it takes for organizations to prepare for series production, we have spent over the last 18 months in R&D and have understood the need for an API-based True Shape Nesting solution that can be utilized beyond just build preparation for costing and planning.”

Optimizing shape-based nesting

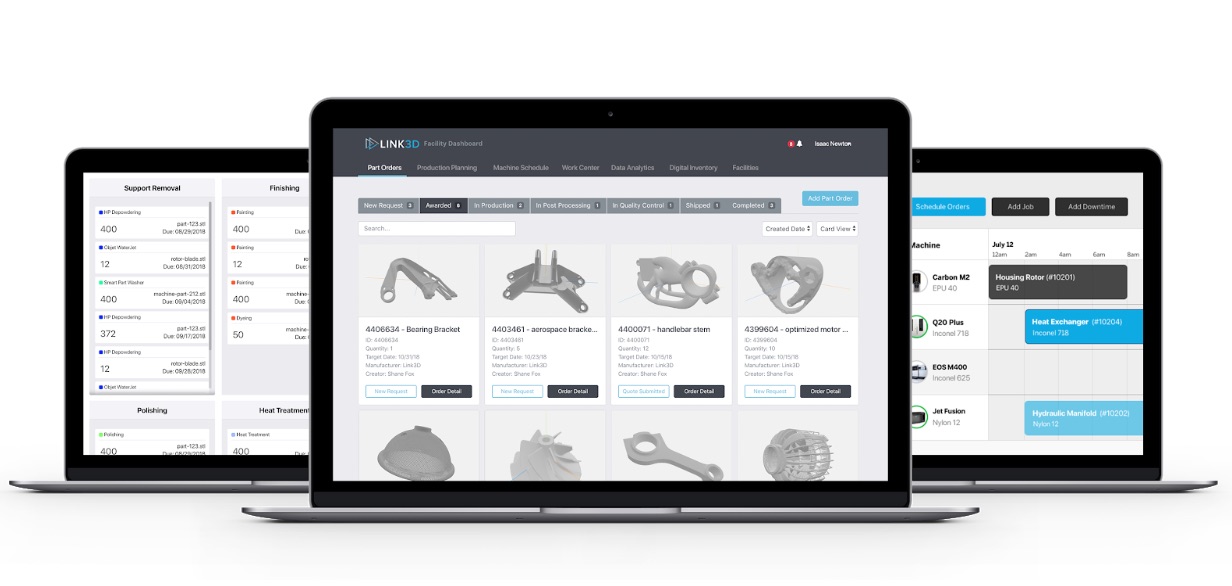

Last year, Link3D released the Production Planning System (PPS) which is designed to aid users in maximizing machine utilization, track and trace yield, and capacity management. This solution is integrated within the company’s Additive Manufacturing Execution System (AMES) & Additive Workflow Software which accelerates overall 3D printing operations for manufacturers.

PPS is powered by the company’s Build Simulation software, which drives auto-quoting, production planning and machine scheduling of 3D printed parts. True Shape Nesting is now a solution within this software. Vishal Singh, CTO of Link3D, added, “Link3D’s production planning tool is developed for companies to adopt serial production with additive manufacturing.”

“With shape-based nesting, Link3D will help additive manufacturing facility operations maximize machine utilization, understand a number of the machine runs needed to fulfill the order and reduce the manual effort with build preparation. It will help our customers reduce cost and drive production efficiency.”

Ramping up serial production

Fox continued, “As Link3D prepares for the future of additive manufacturing, it is our belief that series production will ramp up at an extreme pace. To understand true production cost and achieve optimized production planning, MES toolsets need to become more agile in order to dynamically plan and increase throughput.”

Find out more about Link3D’s software at RAPID + TCT Booth #1749.

Don’t forget to vote for the 2019 3D Printing Industry Awards.

Subscribe to our 3D Printing Industry newsletter and follow us Facebook and Twitter for full coverage of RAPID + TCT. 3D

Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

Featured image shows the True Shape Nesting feature. Image via Link3D.