The Ukrainian manufacturer of Electron Beam Melting (EBM) equipment Chervona Hvilya is showcasing its latest metal additive manufacturing technology, xBeam at RAPID +TCT this week.

xBeam utilizes a hollow conical electron beam as the heating source and a coaxial supply of feedstock wire to produce quality metal 3D printed parts at a fast production rate. The UK research and technology organization TWI is the first to order an xBeam system – the xBeam-18/I metal 3D printer.

“The xBeam system and its unique feature that allows feeding the wire coaxially, will give us the opportunity to explore a great number of possibilities for 3D printing parts with wire,” said Dr. Sofia Del Pozo, senior project leader at TWI.

“The system will offer a high level of flexibility along with precise process control. We are really excited about being the first ones to develop the xBeam coaxial system to produce meter-scale parts for the aerospace sector.”

xBeam additive manufacturing

Chervona Hvilya has over 25 years of experience in developing EBM technologies. The company focuses on EBM for production of high-quality titanium ingots from titanium scrap and sponge-titanium. From its collaboration with various Ukranian scientists, xBeam technology was developed in 2014.

According to Chervona Hvilya, this patented solution is based on the ability of gas-discharge electron beam guns to generate hollow conical electron beam for unique physical conditions for precisely controllable metal deposition. The first xBeam prototype was seen in 2016 and commercialization began last year. Now, the system has been ordered by the likes of TWI to test new materials and its overall capabilities.

The OAAM project

TWI, also known as The Welding Institute, plans to use the xBeam-18/I in the Open Architecture Additive Manufacturing (OAAM) project. Announced in August last year, the OAAM project aims to provide the UK aerospace sector with large scale metal 3D printed components.

Leading this initiative, TWI is working with Chervona Hvilya among others, to develop specialized software for CAD/CAM control interfacing across the range of OAAM EBM technologies, such as xBeam. Upon the arrival of the xBeam system at TWI’s Cambridge facility in the autumn of this year, the partners will seek to advance the capabilities of electron beam wire and laser-powder/laser-wire processes.

To find out more about the xBeam system and Chervona Hvilya, RAPID + TCT attendees can visit booth 1557.

Don’t forget to vote for the 2019 3D Printing Industry Awards.

Subscribe to our 3D Printing Industry newsletter and follow us Facebook and Twitter for full coverage of RAPID + TCT. 3D Printing Industry is the only publication reporting all of the news from the event.

Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

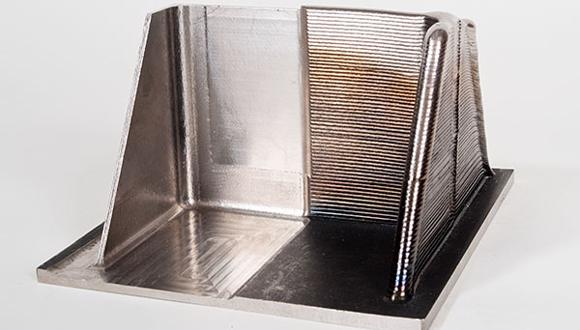

Featured image shows a set of 3D printed cylinders produced on the xBeam system. Photo via Chervona Hvilya.