AMendate, a German provider of fully automated topology optimization software, will present its generative design solution at EMO Hannover 2019 from the 16th to the 21st of September.

The start-up, spinning off from the University of Paderborn, is currently developing an intuitive user interface for 3D printed component optimization thus making the adoption of industrial additive manufacturing easier.

This fits the theme of the upcoming metalworking trade fair which is “Smart technologies driving tomorrow’s production.” Dr. Thomas Reiher, co-founder and CEO of AMendate, said:

“Trade fairs help us to learn and to gain a clearer view of what the market needs. We are digitizing a manual process that can then be supported by artificial intelligence and take place autonomously in the future. This makes us an enabler of additive manufacturing in the mass market, a real driving force behind the production of the future.”

Amendate and generative design

Founded in 2018, Dr. Reiher and co-founders from the University of Paderborn’s Research Center for Additive Manufacturing (DMRC) identified the lack of an accessible and rapid solution for generating and preparing designs for additive manufacturing.

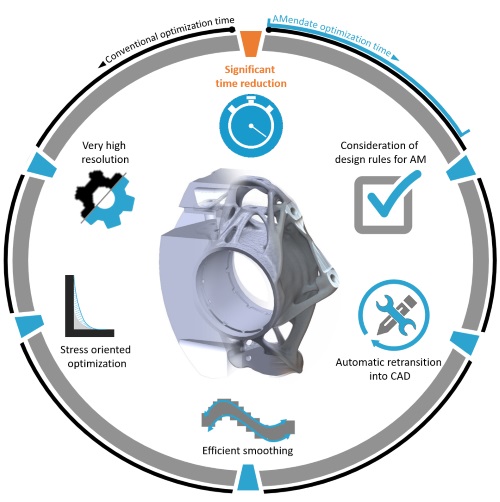

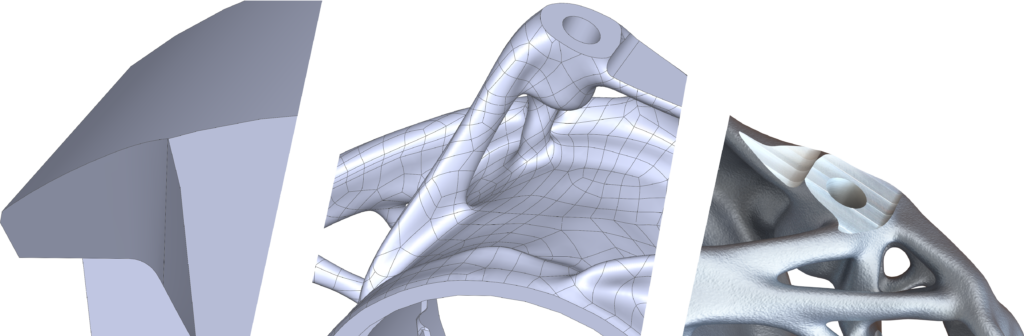

This led to the creation of AMendate’s topology optimization software which is said to transfer designs into an organically shaped part, i.e., generative design. Last year, AMendate was one of five winners of the Formnext Start-up Challenge, as a result of its technology.

In doing so through unique algorithms, a part can be optimized for its loads while reducing material usage and weight. Dr. Reiher added, “Our software ensures that geometries are no longer unintentionally removed during data smoothing. Furthermore, the technology allows work steps to be completed in days that would otherwise take several weeks.”

Enabling additive manufacturing

Dr. Gereon Deppe, a co-founder of AMendate, explained, “Our goal is to be instrumental in shaping the generative design market. Our vision is to be able to optimize all components in the future. This will help reduce raw material consumption levels and promote sustainable production.”

The company hopes to build its network with those attending EMO Hannover 2019, later this year. This includes machinery and plant manufacturers, automotive component suppliers, as well as aerospace and shipbuilding companies.

Find the latest additive manufacturing news by subscribing to our 3D Printing Industry newsletter and following us Facebook and Twitter.

Also, visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

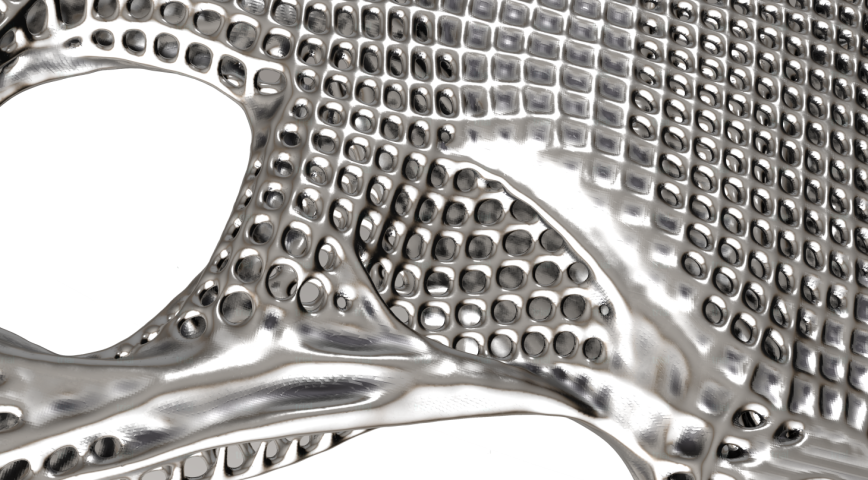

Featured image shows a complex lightweight metal 3D printed structures. Photo via AMendate.