Luxembourgish 3D scanner developer and manufacturer Artec 3D has announced the availability of Artec Studio 14. Complete with seamless integration of all the company’s 3D scanners (the Eva, Space Spider, Leo, Ray and latest Artec Micro) Studio 14 has new features made to facilitate quality inspection and automatic operation.

“The new Artec Studio 14 supports Artec’s entire line of 3D scanners, allowing our users to digitize the very smallest objects, such engine valves or connectors, right up to cargo aircraft, with metrology grade precision,” explains Artyom Yukhin, president and CEO of Artec 3D.

“In addition, all of our new software features lead to a more intuitive user experience for users in every industry, from quality inspection to CGI and 3D printing.”

Industrial features of Artec Studio 14

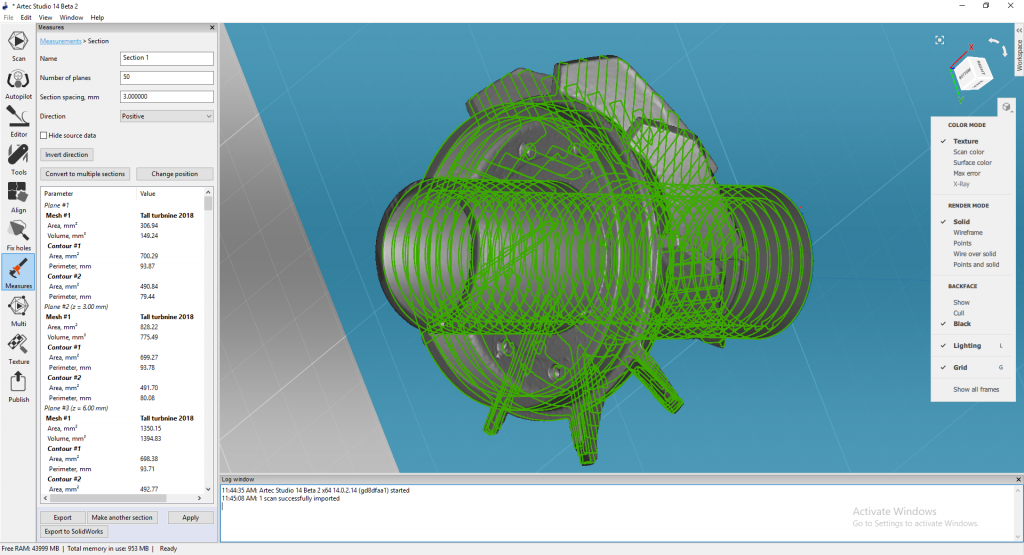

An upgrade of September 2018’s Studio 13, Artec Studio 14 is a powerful 3D scan processing software capable of working with datasets up to 500 million polygons. It is suitable for both small and large scale objects, depending on the hardware used, and can be operated in two modes, either manual or Autopilot.

In manual, users have access to a range of advanced settings, giving full control over the scanning process. Manual tools include automatic base removal for the table/stand/floor beneath a part, scan auto-alignment, and mesh simplification.

Specific to the Ray (Artec’s long-range laser scanner) Studio 14 can be used to perform fast, geometry-only Global Registration of point-cloud data that doesn’t require texture. For industrial applications, i.e. the reverse engineering of parts, all Studio 14 model data can be easily exported to common CAD programs, including SOLIDWORKS, AutoCAD and Design X.

3D scanning in autopilot

New to Artec Studio 14, Autopilot gives users the option to automatically undertake some stages of the data processing step. With this mode selected, Artec Studio 14 guides operators through the 3D scanning process and, by answering questions about the scanned object, the software selects the most effective algorithms to create a finished 3D model. It also allows users to automatically position models so they always appear from a certain angle when opened.

Beyond Autopilot, Artec Studio 14 is now able to perform an automatic surface analysis of challenging objects, i.e. those with a black or shiny finish. Part of this analysis is the Automatic Glare Removal feature and Dynamic Auto Brightness. Used together these features can be adjusted by the user to retain the original color of the scanned object as demonstrated by the before and after models below.

Small holes and gaps created during scanning can also be automatically fixed by the Bridges features in Artec Studio 14.

This latest software update is available now though Artec 3D for Windows PCs, Macs and tablets.

Stay tuned to find out this year’s winners of the 3D Printing Industry Awards.

For all of the latest 3D scanning and additive manufacturing news subscribe to the 3D Printing Industry newsletter and follow us Facebook and Twitter.

Featured image shows part and 3D scan in Artec Studio 14. Photo via Artec 3D