Sigma Labs, the computer-aided inspection (CAI) software company behind the patented quality assurance system PrintRite3D, has launched PrintRite3D Version 5.0 at RAPID + TCT this week.

John Rice, CEO of Sigma Labs, said, “Companies engaged in metal additive manufacturing have traditionally been hindered by the inability to analyze the structure of a part during the manufacturing process as well as the inability to make real-time adjustments to ensure an acceptable level of quality.”

“PrintRite3D Version 5.0 resolves this challenge with results comparable and complementary to CT testing. This genuine advance provides value to OEMs and manufacturers, and is designed to increase production yield of 3D metal manufactured parts, cut post-process quality inspection costs and reduce time to market.”

The PrintRite3D platform

Based in Santa Fe, New Mexico, Sigma Labs has developed the PrintRite3D platform with software modules INSPECT, CONTOUR and ANALYTICS for in-process quality assurance for metal additive manufacturing.

This platform uses sensor data and other required hardware to collects real-time data during 3D printing. The PrintRite3D INSPECT software monitors the metallurgical properties of the part while PrintRite3D CONTOUR is used to keep track of anomalies in the part geometry. Finally, PrintRite ANALYTICS provides management and seamless access to all in-process and post-process data over the entire product life cycle.

PrintRite3D Version 5.0

With the latest update, PrintRite3D Version 5.0 can detect melt pool disturbances through thermal signatures in metal powder bed fusion processes. Using co-axial Planck thermometry, this platform is able to verify the thermal signature in both temperature and coordinates.

More specifically, Version 5.0 uses In-Process Quality Metrics (IPQMs), Thermal Emission Density (TED), and Thermal Emission Planck (TEP) to analyze internal thermal signatures and melt pool disturbances. Furthermore, a graphical user interface for real-time display of live part quality results is provided as well as automated anomaly detection thermal mapping imaging function.

Rice added, “We believe the launch of this new product, coming after the news of DARPA’s recently published conclusion that Sigma’s technology can be used as the compliance means for certifications and/or certification of components of 3D metal parts, has the potential to advance the metal AM industry significantly.”

Sigma Labs can be found at RAPID + TCT booth 1953.

Don’t forget to vote for the 2019 3D Printing Industry Awards.

Subscribe to our 3D Printing Industry newsletter and follow us on Facebook and Twitter for full coverage of RAPID + TCT from 3D Printing Industry.

Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

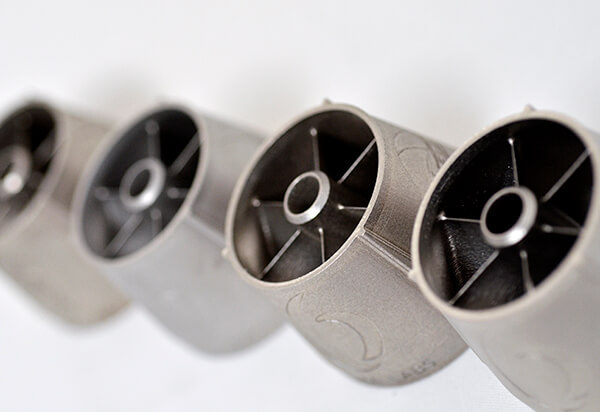

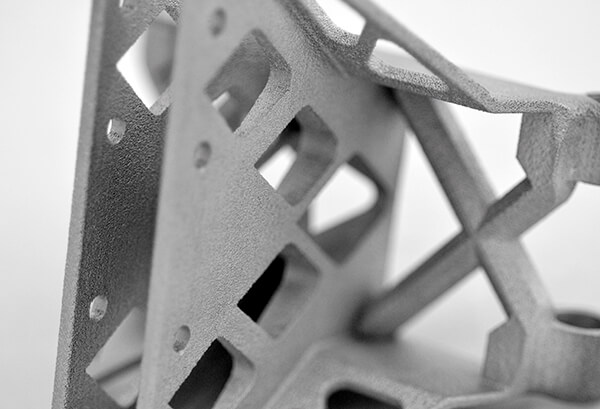

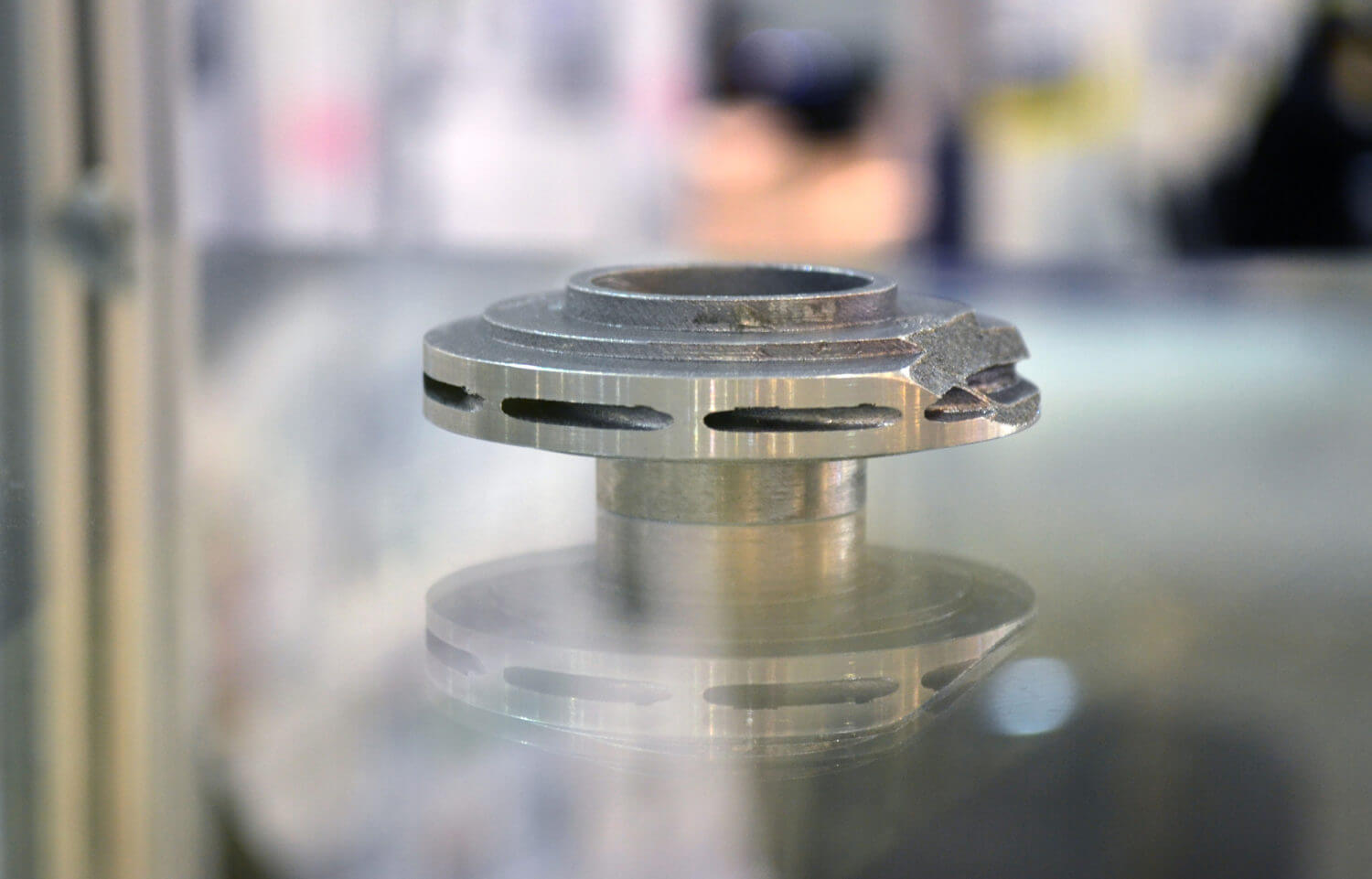

Featured image shows 3D printed metal parts inspected by the PrintRite3D platform. Photo via Sigma Labs.