LINK3D, a New York-based 3D printing workflow software provider, has partnered with EOS North America to accelerate its client’s additive manufacturing workflow.

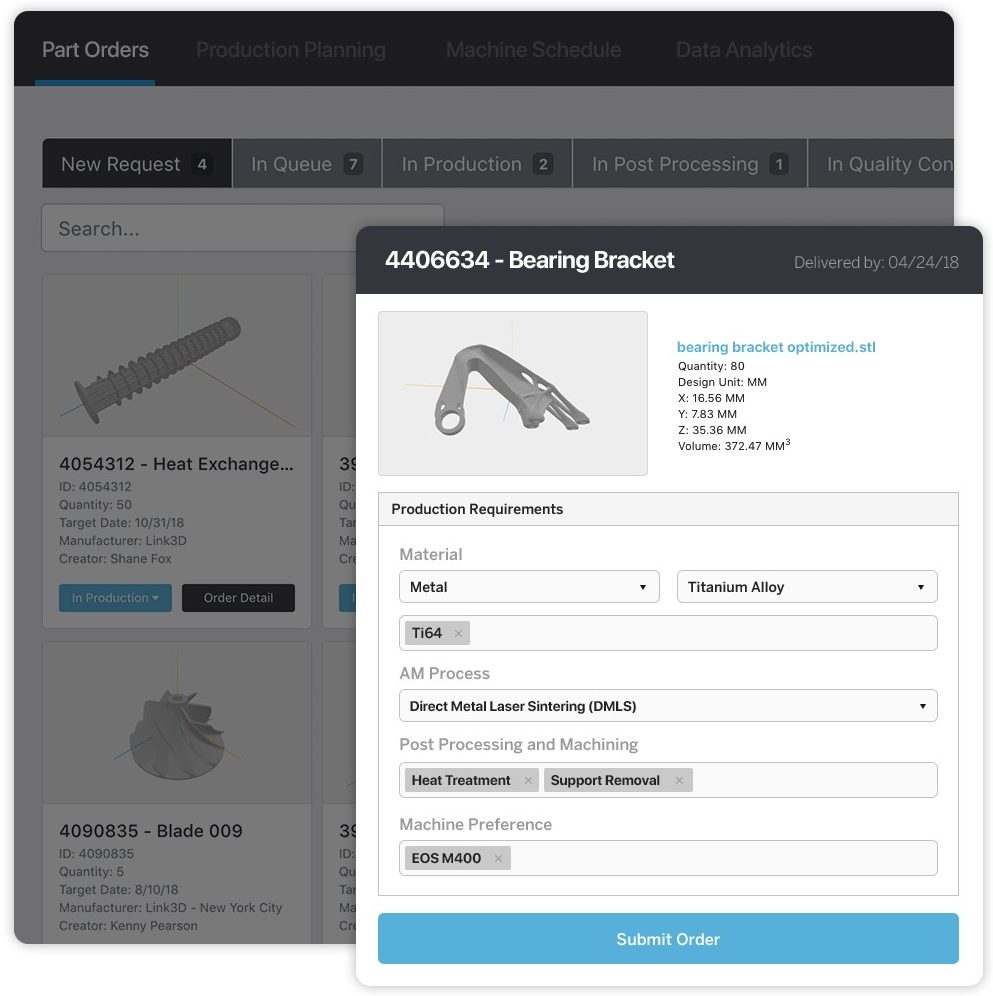

In an ongoing proof of concept trial, LINK3D has integrated its Additive Manufacturing Execution System (AMES) & Additive Workflow Software internally as a solution for EOS and its customers to accelerate overall 3D printing operations.

“LINK3D is humbled to have its Additive MES solution selected by EOS North America to power its metal benchmarking facilities,” said Shane Fox, CEO of LINK3D.

“We are excited to help increase EOS North America’s operational efficiencies and have our technology integrated into their ecosystem to enable their customer experience.”

Testing the additive manufacturing workflow

Within its two technical facilities in Pflugerville, Texas, and Novi, Michigan, EOS North America performs benchmark studies for its customers to gauge how additive manufacturing processes can be managed in a distributed manufacturing model.

To enhance this process, the company has sought out LINK3D’s AMES & Additive Workflow Software. This technology is used for streamlining OEM’s internal and external additive manufacturing production. Furthermore, this workflow can speed-up order turnaround time, maximize machine utilization rates, and provides a “superior experience” for all engineers to gain access to an additive supply chain.

EOS believes that the capabilities of LINK3D’s technology tie into its holistic solution for 3D printing which is to empower customers to understand the true potential of additive manufacturing for production. Dr. Greg Hayes, Director of Applications, EOS North America stated:

“We consistently strive to work with cutting-edge organizations. This includes material, software and hardware solutions for the additive manufacturing industry [thus] LINK3D is one of our choices for software solutions.”

EOS North America is also time testing LINK3D AMES system and Build Simulation software for quoting and costing for its clients.

Streamlining additive manufacturing

LINK3D has actively integrated and improved its technologies to enhance the capabilities of additive manufacturing. Recently, the company partnered with the German R&D hub Aachen Center for Additive Manufacturing (ACAM) to promote industrial 3D printing in Europe.

In addition, at Formnext 2018, LINK3D launched its Post Processing Management Technology for within its AMES platform. This tool is designed to optimize downstream manufacturing processes within a 3D printing supply chain.

Stay up to date with LINK3D and the latest 3D printing news by subscribing to our free newsletter. Also, follow us on Twitter and like us on Facebook.

To commence your career in additive manufacturing or post new opportunities, join 3D Printing Jobs.

Featured image shows Real-time collaboration in the LINK3D’s AMES software. Image via LINK3D.