LINK3D, a New York-based 3D printing software provider, has launched its Post Processing Management Technology for additive manufacturing at Formnext.

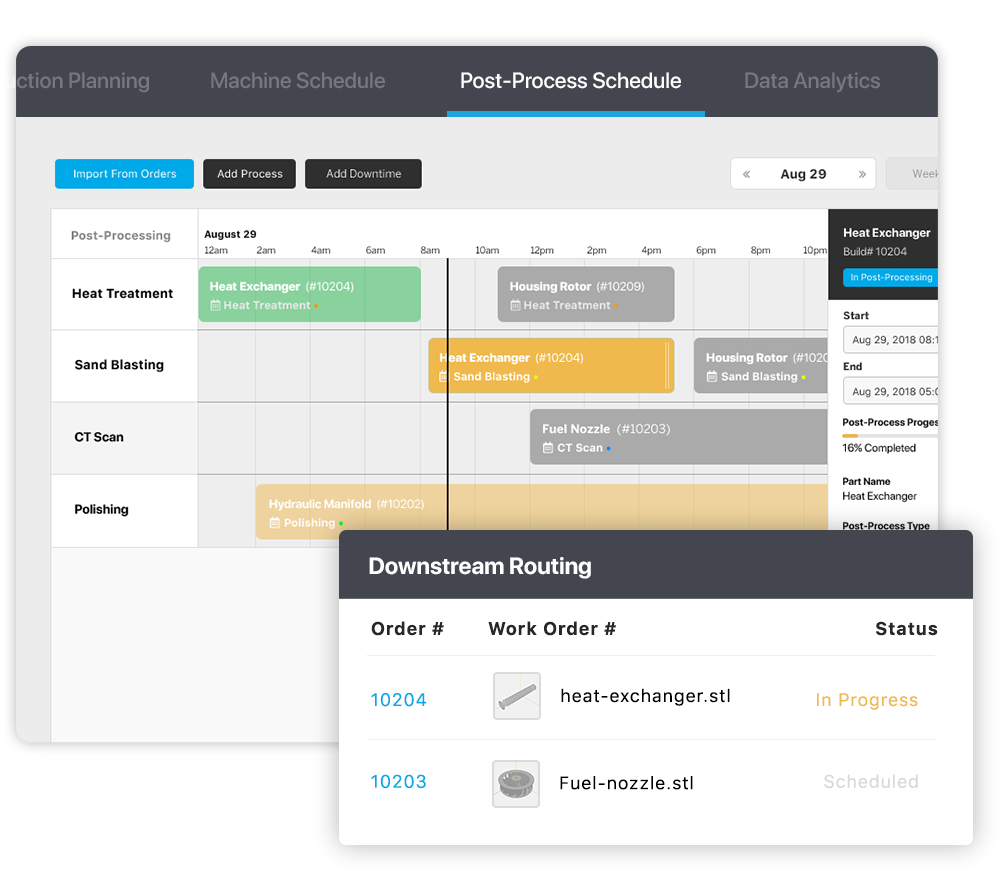

Contributing to the company’s Additive Manufacturing Execution System (AMES) & Additive Workflow Software, the Post Processing work management and scheduling tools are designed to optimize downstream manufacturing processes within a 3D printing supply chain.

“With dynamic routing and smart scheduling algorithms, Link3D aims to drastically improve the operational efficiency of additive production, particularly for OEM’s looking to adopt series production,” said Vishal Singh, Co-Founder and CTO of Link3D.

Post Processing Management Technology

With a focus on centralizing industrial 3D printing workflows, Link3D has developed various additive manufacturing technologies to accelerate and automate production. Recently, the company launched its Production Planning System (PPS) designed to aid users in maximizing machine utilization, track and trace yield, and capacity management.

Now, Link3D has further improved planning with Post Processing Management Technology. Singh added, “Capturing and tracking data at each stage creates the perfect platform to enables data-driven automation.”

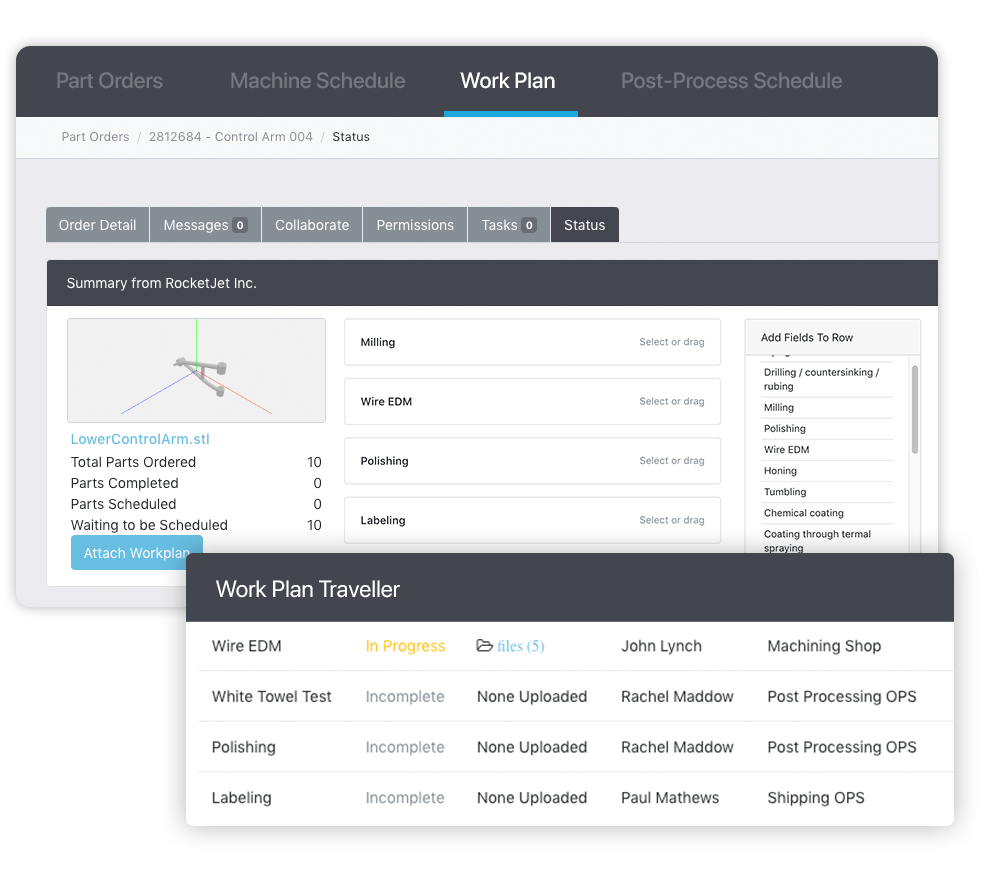

This technology enables the creation of post processing work plans for individual part orders, as well as provides detailed post-processing information including responsible parties, descriptions, and checklists for each step in the development of the part. In addition, it offers drag-and-drop lists of production schedules for thorough activity traceability.

The Yield Management System

According to Link3D, OEMs and service bureaus oftentimes need to introduce multiple digital and offline systems to manage their additive manufacturing production. Thus, the company has streamlined such post-processing systems with an improved yield management function.

The closed-loop yield management system identifies whether parts should be reprinted due to failures during any post-processing stage. Shane Fox, Co-Founder and CEO of Link3D concludes:

“Link3D believes in developing technology to increase productivity and help organizations scale to series production. A true additive manufacturing execution system is crucial to achieve this mission.”

Formnext visitors can find more about the Post Processing Management Technology at Link3D’s stand, Hall 3, Booth B46.

Stay updated with the latest additive manufacturing news from Formnext by subscribing to the 3D Printing Industry newsletter. Also, find us on Facebook and like us on Twitter.

For new opportunities across additive manufacturing visit 3D Printing Jobs.

Featured image shows the Post Processing Management & Work Plan tool. Image via Link3D.