PostProcess Technologies, an automated post-printing developer, has partnered with New York based non-profit research and development institute CUBRC to accelerate its digital capabilities for 3D printing.

CUBRC pioneers state-of-the-art technology Defense, Intelligence and Homeland Security communities. As a result of this collaboration its Heartwood Analytics suite, a data-agnostic tool, will be leveraged to digitize the additive manufacturing process within PostProcess Technologies’ software.

“We are very excited about bringing CUBRC’s advanced machine learning capability to PostProcess to accelerate the groundbreaking work that the team at PostProcess have done,” said Dr. John Coles, project leader at CUBRC.

“Our efforts in developing a class of technologies that turn massive amounts of data into actionable information for decision makers is a perfect fit for PostProcess’ applications and mission.”

Completing the digital thread

According to Daniel Hutchinson, Founder and CTO of PostProcess, the lack of data for post-printing fundamentally weakens the additive manufacturing design process and limits critical properties in the 3D printed finished part.

Thus, earlier this year, the company introduced the CONNECT3D extension for its AUTOMAT3D software platform. This addition extends tools to the cloud to complete the digital thread between design, additive manufacturing, and post-processing.

This technology uses a data science approach for 3D post-printing and performance improvement. The machine learning capabilities remove manual steps and guesswork that customers are currently required during support removal and surface finishing.

CUBRC’s Heartwood Analytics

Heartwood Analytic was developed over the past 10 years by CUBRC’s Data Science and Information Fusion (DSIF). The platform features smart integration of diverse data sources, streaming multi-source data fusion, deep market insights, population-specific predictive models, and personalized engagement optimization. Integrating this platform with will more efficiently develop and utilize insights driving increased performance and predictability within PostProcess’ AUTOMAT3D.

“PostProcess was founded on software as the first component of our solution,” added Hutchinson. “We’ve known since the beginning that data analytics was an essential part of doing data science at scale. That’s why we’ve chosen CUBRC for its experience and expertise in data extraction, alignment, analysis and systems optimization technologies to enhance and expedite our post-printing software platforms.”

PostProcess Technologies previously signed two regional sales partnerships in the U.S., with Prototyping Solutions and the TekPro Group.

Keep up with the latest 3D printing software developments by subscribing to our free newsletter. Also, follow us on Twitter and like us on Facebook.

To commence your career in additive manufacturing or post new opportunities, join 3D Printing Jobs.

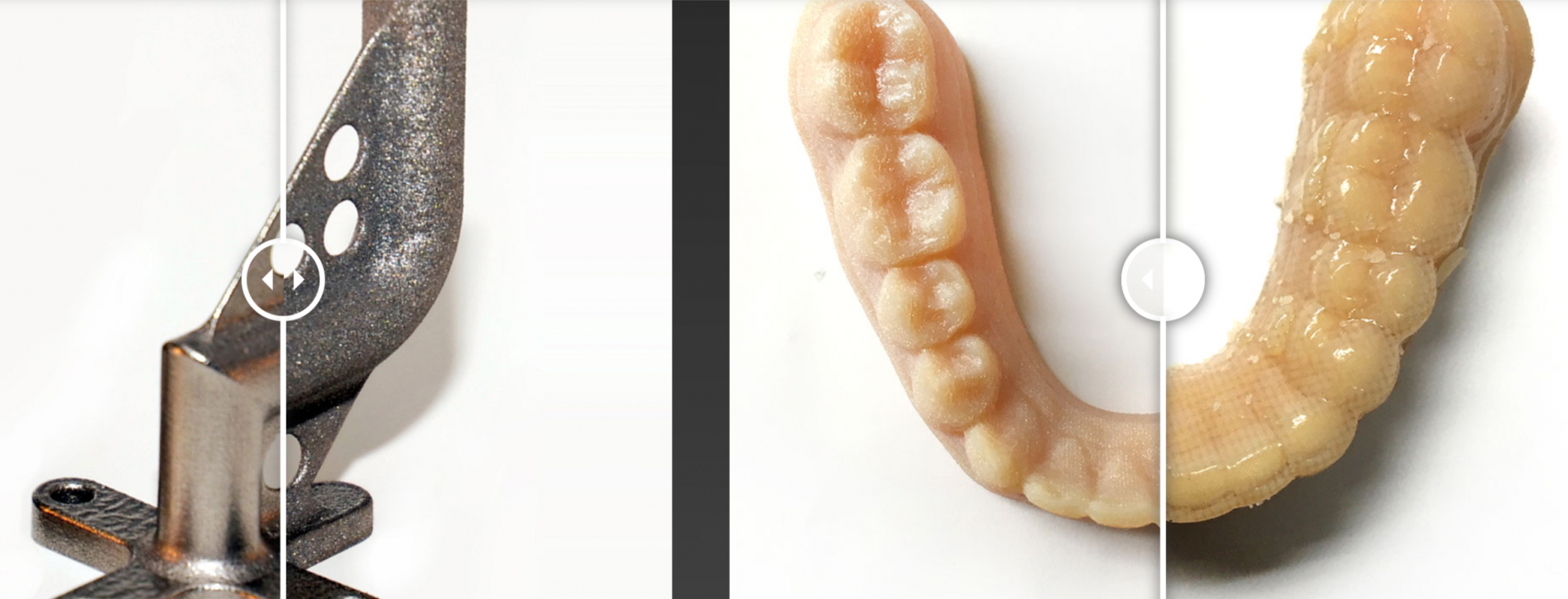

Featured image shows a depiction of PostProcess Technologies breakthrough software. Image via PostProcess Technologies.