Many companies offer post-processing solutions to businesses that have adopted 3D printing as part of their manufacturing and production workflow, but those companies generally offer them as secondary services. However, Postprocess Technologies — as you can surmise from the name — is a company dedicated entirely to treating and processing 3D printed parts and components.

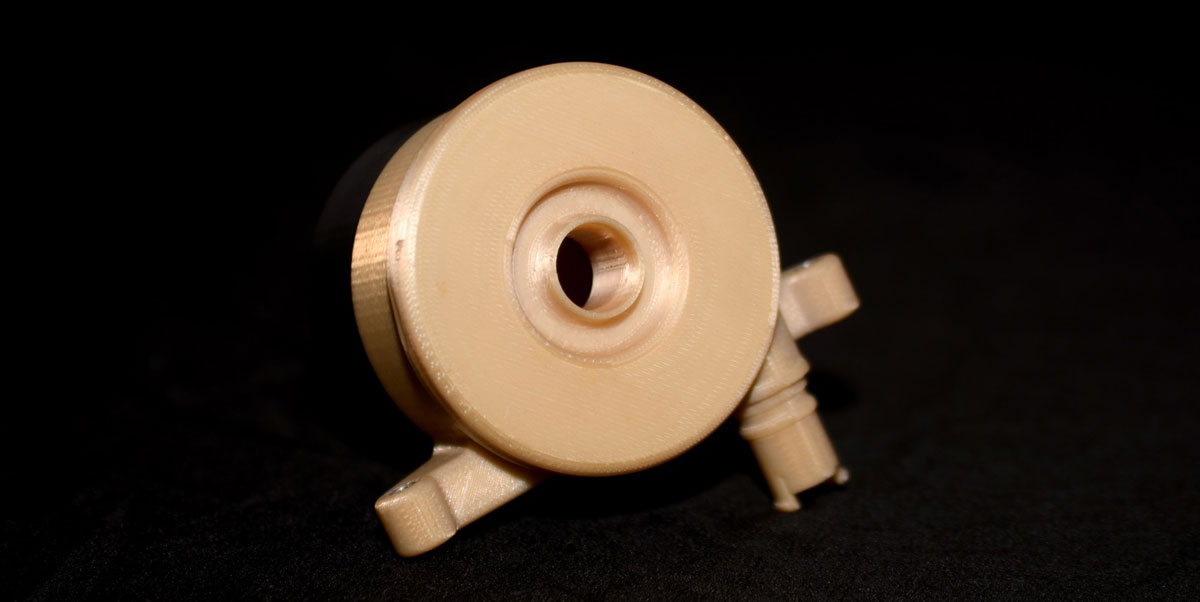

The company primarily focuses on the removal of 3D printed support material, surface finishing and smoothing and the removal and minimization of waste water by-products from the cleaning process.

Thier support material removing machines utilize a combination of water and ultrasonic waves to reduce waste water and speed up the support removal process. Companies can purchase them in multiple sizes and configurations depending on the volume of cleaning required and the types of 3D printing process that was used. Their machines can accommodate parts as large as 36in x 36in x 36in, so they are able to accommodate just about any business or manufacturer.

They also offer multiple finishing and surface smoothing services, including the use of chemicals, sealants, coatings and the use of finishing media. Finishing media are small, angular objects made of various materials that are placed in large agitating machines with the 3D printed parts. The layer lines on 3D printed objects will be worn down and are gently removed by the agitator. The type of media used is dictated by the type of 3D printed object and the material used to print it.