What gave Einstein so many bright ideas? How are 3D printed fakes entering the art world? Where can I get a 3D printed Tiny Rick? How many hours does it take to design a 3D printed dress?

These questions and more from metal additive manufacturing to desktop 3D printing are answered in this edition of our Sliced 3D printing news digest.

The first of the week’s round-ups also features, PostProcess Technologies, CTC GmbH Stade, Damien Hirst, Coventry’s Manufacturing Technology Centre (MTC), Nano Dimension, Arcam, DOBOT, and the ‘Father of Titanium.’

What’s possible with 3D printing?

Tiny Rick, a younger version of the character Rick in Rick and Morty been given a new storyline by designer and YouTuber 3D Print Guy. The product of popular demand by fans, an exclusive Tiny Rick model is now 3D printable and features in a unique animated short on 3D Print Guy’s channel. You can get the .stl files here. Enjoy!

Damien Hirst’s mockumentary Treasures from the Wreck of the Unbelievable, that features 3D printed artworks lifted from the sea, is now available on Netflix. The film chronicles the fictional lead-up to Hirst’s show at the Venice Biennale in 2017.

Under the Real Play Coalition, the LEGO Foundation, Unilever and IKEA have released a 3D printing kit for a set of toy blocks that used to belong to Albert Einstein.

To get ahead in additive manufacturing, UK based SMEs GRM Consulting Ltd. and K-Tech have enlisted the help of Coventry’s National Manufacturing Technology Centre (MTC) to help optimize their software for metal 3D printing. In two successful test prints, GRM and K-Tech successfully produced motorbike forks, optimized for toughness vs. weight.

Martin Gambling, Managing Director at GRM, comments, “The MTC’s experience in additive manufacturing technologies has been a great help in ensuring our tools compliment these emerging technologies.”

Seattle running shoe maker Brooks is the latest to enter the custom-fit sneaker race with a 3D scanning partnership with HP.

And a 3D printed dress is the centrepiece of the Remarkable campaign at Griffith University, Australia, that seeks to encourage research innovation. The dress was designed over 400 hours by Queensland College of Art lecturer Dr Sam Canning, and is made of 25,000 to 30,000 individual pieces.

Deals in 3D printing

Trideus has become a reseller of BigRep 3D printers and hardware in Belgium, the Netherlands, and Luxembourg.

Nanyang Technological University, Singapore (NTU Singapore) has become the latest customer of a Nano Dimension DragonFly 2020 Pro electronics 3D printer.

Following the proposal from GE Additive at the beginning of January, Arcam AB has now official delisted from the Nasdaq Stockholm exchange. The last day of trading was January 26, 2018.

PostProcess Technologies has signed two regional sales partnerships in the U.S., one with Prototyping Solutions in Buffalo, NY and the second with the TekPro Group, headquartered in California. According to the company, it is the first “to automate post-printing for the industrial 3D printing market.” The new partnerships will help PostProcess reach its market potential.

A step forward for 3D bioprinting and medtech

And researchers at Pennsylvania State University have found that mixing different forms of PDMS/silicone can promote cell adhesion in 3D bioprinted scaffolds.

In the latest from 3D printing trends in healthcare, Augusta University Medical Institute, Georgia, has adopted the technology to make education models for its students. The program currently focuses on critical models such as the heart, brain and spinal chord.

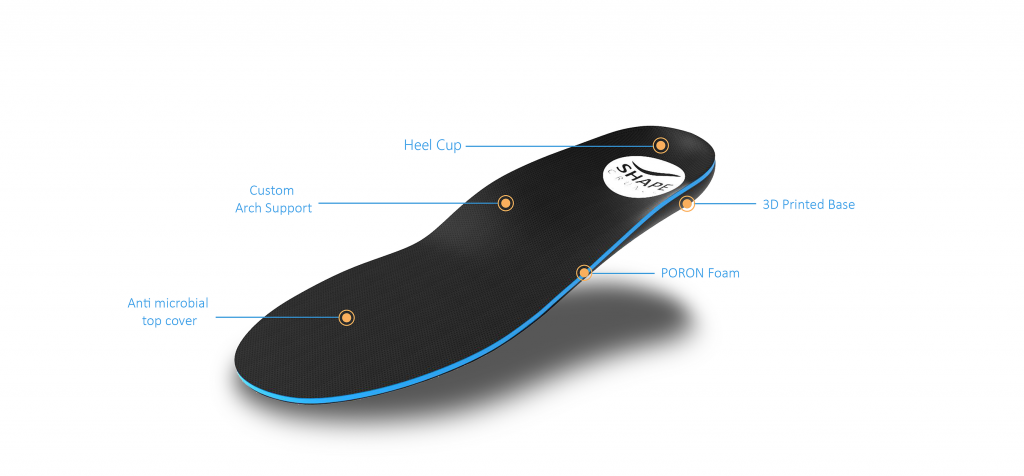

Combining computer-vision, machine learning and 3D printing, Shapecrunch in Delhi, India, is making custom insoles for people with foot problems. Co-founders Nitin Gandhi explains the thought behind the project, “I went to the doctor and he told me to get a pair of custom orthotics. Then I went to a shop to get those made and was surprised to see the manual process,”

“All the machines were imported and the orthotics that I finally got had to be replaced because they were uncomfortable […] Since were already working in 3D printing, we thought how if we 3D print the insoles and see if it’s comfortable. It actually worked.”

Education with bite

DOBOT, a CES 2018 Innovation Awards Honoree, came to the UK Beat show last week to exhibit it’s educational potential. DOBOT founder and CEO Jerry Liu comments, “DOBOT hopes that each kid can enjoy the pleasure taken by robots and artificial intelligence, that’s what we are striving for!”

A University of Washington study, involving experiments with a 3D printer, has discovered more about how mosquitoes know just the right time to bite. Ouch!

What’s new in materials?

Traxer, a 3D printing service provider based in Germany, has released 3DWASH, a new, eco-friendly cleaning agent. 3DWASH is specified for use on alkali-based support materials, such as those 3D printed on the Stratasys Fortus series.

Orbital Composites’ patented carbon fiber 3D printing method is undergoing research at Airbus subsidiary CTC GmbH Stade. In the project CTC is investigating ways the technology can be used to 3D print large areas, like rotor blades and aircraft wings, and work up to 100 times faster than other continuous fiber-reinforced plastic additive manufacturing.

Stanley Abkowitz, known as the ‘Father of Titanium’ has passed away at the age of 90. In 1951, Abokowitz invented Ti-6Al-4V at a U.S. Army laboratory. The titanium-aluminum mixture has since become one of the most commonly used titanium alloys in the manufacturing industry. It’s powdered form is used in metal 3D printing by the likes of GE Aviation, Digital Metal and DARPA.

Let us know what you think are the most important applications of 3D printing. Make your nominations for the 3D Printing Industry Awards 2018 now.

For regular updates on the world of 3D printing, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows the Sliced logo over a 3D printed Tiny Rick. Photo via 3D Print Guy.