6K Energy, a division of advanced material specialist 6K, has signed a strategic supply agreement with metal recycling firm Aqua Metals.

Through this partnership, the two companies are working to establish a circular material supply chain for lithium-ion battery materials, said to be the first of its kind in North America.

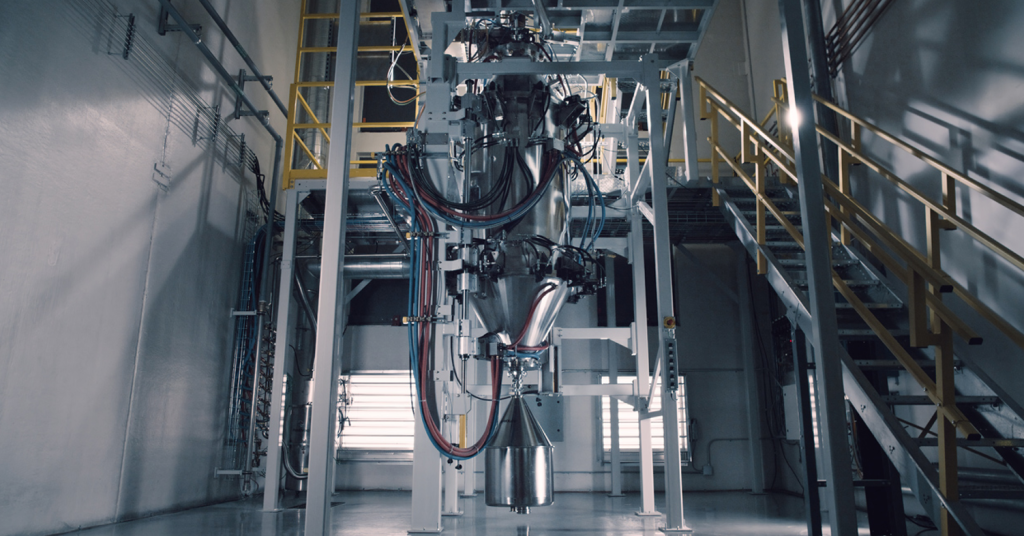

The agreement will see Aqua Metals supply 6K Energy with recycled battery materials from its Sierra ARC facility based in Reno. Leveraging its proprietary UniMelt microwave plasma technology, 6K will convert these critical minerals into cathode active materials (CAM) at its PlusCAM factory in Jackson, Tennessee.

The company will then sell the recycled CAM to domestic battery manufacturers, creating a fully circular US-based supply chain.

The agreement aligns with the US Government’s efforts to re-shore its manufacturing capabilities, amid global trade challenges and increased emphasis on environmental sustainability. By 2030, the lithium-ion battery manufacturing capacity in the US is expected to reach nearly one terawatt-hour.

As such, the partnership will qualify for domestic content incentives under the Inflation Reduction Act (IRA).

“This agreement extends beyond a supply contract; it’s a partnership aimed at redefining industry standards for environmental responsibility and cost-efficiency in battery material production,” commented 6K Energy President Sam Trinch.

“6K Energy will be the first in North America to incorporate large quantities of sustainably recycled metals into our advanced battery materials using our low-cost, low-carbon footprint CAM production technology.”

6K’s UniMelt technology

6K Energy claims that its UniMelt technology can produce most materials needed for manufacturing lithium-ion batteries, including NMC, LFP, LLZO, LNMO, LMO, LTO, and silicon anode.

Producing zero liquid or solid waste, UniMelt boasts a minimal carbon footprint. The technology reportedly produces 70% less greenhouse gas emissions than alternative material recycling processes.

Unlike other multi-step methods, UniMelt produces feedstock in a single closed-loop step. This is said to lower production process times by 95%, translating to 50%-60% reductions in material conversion costs.

In addition to the production of lithium-ion battery materials, UniMelt technology is also heavily deployed by 6K Additive, 6K’s 3D printing division, to produce 3D printable metal powders from scrap material.

It was announced last year that 6K Additive had partnered with medical manufacturing firm Surgical Metal Recycling to recycle end-of-life surgical implants. Here, UniMelt is used to convert the implant components back into titanium powder, which can then be used to 3D print new implants.

Speaking to 3D Printing Industry at RAPID + TCT 2023 Leslie Frost, 6K Additive’s Senior Director of Marketing, stated that this process enables an “incredibly sustainable and circular supply chain.”

Elsewhere, 6K Additive has partnered with French industrial metal 3D printing specialist Z3DLab to produce its ZTi titanium alloys range. Leveraging UniMelt technology, 6K additive processes the ZTi alloys into spherical, dense powders optimized for additive manufacturing, achieving up to 100% yield.

A US-based circular supply chain for battery materials

Through the strategic supply agreement, which will begin this year, Aqua Metals has committed to providing 6K Energy’s PlusCAM facility with 30% of the nickel and lithium carbonate it needs for CAM production.

This agreement will enable North American electric vehicle (EV) and lithium-ion battery manufacturers to access domestically produced cathode materials that are affordable and possess a low-carbon footprint.

What’s more, the collaboration seeks to address a growing demand for the recycling of manufacturing scrap and end-of-life batteries, while reducing reliance on minerals imported from overseas. Based on current metal prices, the materials supplied under this partnership will have an estimated value of more than $50 million once both companies’ facilities reach full capacity.

“Our strategic agreement with 6K Energy represents a pivotal moment in our mission to build a more sustainable battery ecosystem from the ground up here in North America,” commented Steve Cotton, President and CEO of Aqua Metals.

“Together, we are demonstrating the viability and economic benefits of closed-loop recycling for critical battery metals and laying the foundation for the US to claim leadership in this rapidly accelerating global industry.”

Securing circular supply chains

The emergence of global threats to imports, such as the COVID-19 pandemic, conflict in Ukraine, and attacks on commercial shipping, has resulted in the increased adoption of additive manufacturing to secure and re-shore circular supply chains within the US. This adoption has also been driven by efforts to develop more environmentally sustainable manufacturing methods.

Last year, North Carolina-based titanium developer IperionX entered into an agreement to supply multinational automotive manufacturer Ford with 100% recycled titanium. This agreement forms parts of the two companies’ ongoing collaboration to design, test, and 3D print titanium components for Ford Performance production vehicles.

The deal supports Ford’s efforts to reduce its carbon footprint, with the company committing to achieving carbon neutrality by 2050. Significantly, IperionX-produced titanium can be fully recycled at the end of the product life-cycle, allowing for a fully circular, low-carbon, and US-based automotive supply chain.

Last year also saw IperionX secure key development permits for its Tennessee-based Titan project. Titan plays a key role in securing the US-based material supply chains for titanium and rare earth minerals used in defense, EV, and renewable energy applications. Ultimately, this project plays a key role in achieving the company’s goal to create a fully circular supply chain of titanium in North America.

Away from the US, a €5.6 million European Union (EU)-funded project was recently launched to promote the remanufacturing and create a fully-circular domestic supply chain within Europe. Called CREDIT, the project will develop a new AI-powered digital platform to support the remanufacturing process and promote circularity of firms within the home appliance, automotive, telecommunications, and aerospace industries.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows the 6K Energy PlusCAM factory. Image via 6K Energy.