A study produced by four research institutions in Brazil combines two 3D printable polymers into structures ideal for cell-growth. Known as cell scaffolds, these structures are used in regenerative medicine; i.e. repairing the damage to human organs by using the body’s own cells.

3D printing and electrospinning

PCL is commonly used in 3D printing as it is biodegradable and has a low melting point. PLGA is a copolymer often used to make medical devices. Both plastics are approved for non-toxic compatibility within the body by the FDA.

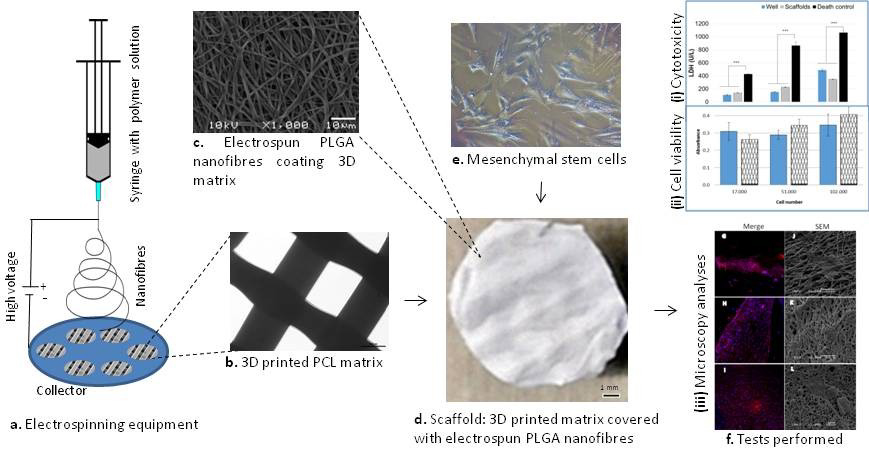

In this study, 3D printed PCL is coated with PLGA using an electrospinning technique. The benefit of electrospinning is that it doesn’t require high temperatures to control a liquid polymer. It also blocks any harmful solvents from entering into a finished object.

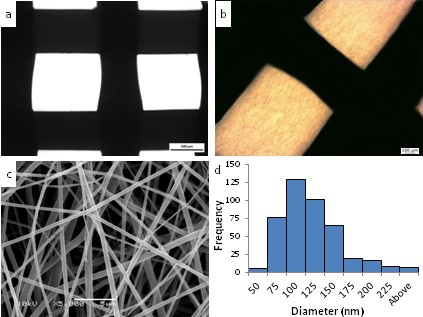

Discs of PCL are 3D printed on a custom made 3D printer. One batch of the discs then get coated in PLGA giving them a woven, microscopic finish.

Double sided scaffolds for “accelerating the regeneration time”

All discs are then laced with stem cells, and monitored for the ability to culture cells. By comparison to PCL alone, PLGA coated PCL promotes better cell attachment due to the varied porosity of the surface.

In addition, the researchers were able to coat both sides of the scaffold to create denser tissue. The authors explain,

A different approach of seeding cells on both sides of the scaffolds was used with the aim of increasing cell density. Thus, it is possible to have stem cells on both sides of the scaffold when transplanting this material to injured tissue, presumably accelerating the regeneration time.

Finding the right combination

TPU, PLA, and graphene oxide have also been combined to created stronger 3D printed scaffolds for cell-growth. Other scaffolds, such as those by Northwestern University, have been fused with calcium-based powders and silk to 3D print structures suitable for cell growth. Finding the right combination of materials could be key to the dream of growing organs suitable for human transplants.

Mesenchymal stem cells cultivated on scaffolds formed by 3D printed PCL matrices, coated with PLGA electrospun nanofibers for use in tissue engineering is published online in the journal Biomedical Physics & Engineering Express. It is co-authored by Natasha Maurmann, Daniela Pereira, Daniela Burguez, Frederico Pereira, Paulo Inforcatti Neto, Rodrigo Rezende, Douglas Gamba, Jorge Silva and Patricia Pranke.

Place your votes in the 1st Annual 3D Printing Industry Awards now.

To stay up to date on 3D printing in medicine, sign up to the 3D Printing Industry newsletter, and follow our active social media channels.

Featured image shows construction scaffolding. Photo by Hans Splinter, archeon on Flickr