Research from the FEM Research Institute for Precious Metals and Metals Chemistry in Germany demonstrates a method of selective laser melting (SLM) in gold. The method could give more design freedom to 3D printed jewelry, watches, and even electronics that use gold as a conductor.

Refined gold

Though SLM is a popular method for 3D printing titanium, aluminium or steel alloys, the authors explain that “Gold and silver alloys are very difficult to process by laser melting because of their high reflectivity and thermal conductivity.”

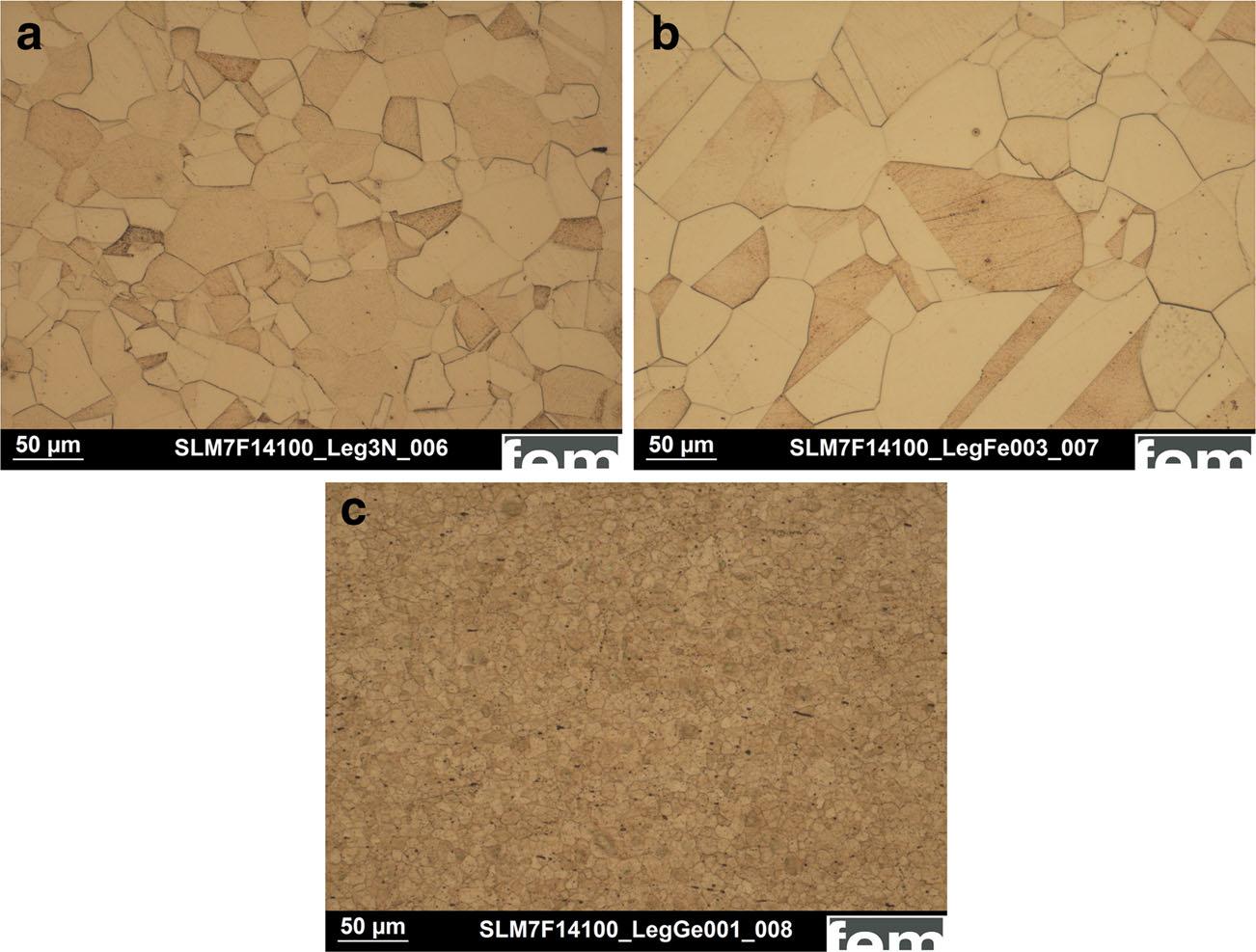

In order to refine these qualities for 3D printing, the researchers combine gold with other metal alloys such iron (Fe) and germanium (Ge). The success of each additional alloy is measured for its hardness, and an ability to mix without creating notable changes to the color of the yellow gold.

Ge001 and Fe003 strains were found to be the most applicable for additive manufacturing. As the Fe and Ge powders are oxidised, these combinations result in less light being reflected by the gold alloy.

Research findings

The FEM Research Institute use an MLab R Laser CUSING machine from Concept Laser for the study. For each alloy combination, additive manufacturing settings are also changed. To this effect, the paper concludes with the optimal parameters for 3D printing gold alloy on the machine. These include:

- Optimal powder size: 5–30 μm.

- Ideal laser speed: 200–450 mm/s.

- Reduced porosity with heat treatment from 3-4% to 0.7%

- Additional porosity control with “Alloying additions of Fe and Ge”

Gold 3D printing casts

3D printing is typically used in jewelry design to create molds for casting metals. In this traditional “lost-wax method” the 3D printed design is used as a sacrificial material that is melted or burned out by liquid metal. This year’s Oscars were created using 3D printed wax models.

With SLM the process is much more direct, allowing for further complexity of designs, and creating less waste material.

The paper Optimization of 18-karat yellow gold alloys for the additive manufacturing of jewelry and watch parts is co-autherd by Ulrich E. Klotz, Dario Tiberto and Franz Held. It is published online in ‘Gold Bulletin: The journal of gold science, technology and applications.’

Vote now in the 3D Printing Industry Awards. Sign up to our newsletter and follow us on twitter.

Featured image shows a pot of gold coins. Photo by Jeremy Schultz, tao_zhyn on Flickr