According to the UK’s Manufacturing Technology Centre (MTC), control is the key factor for the implementation of additive manufacturing in an industrial setting.

Speaking at today’s Additive World conference, in which 3D Printing Industry is in attendance, the MTC’s David Wimpenny explains the most important obstacles additive manufacturing needs to address.

David Wimpenny is the Chief Technologist for Component Manufacturing at the MTC and has over 25 years of additive manufacturing research under his belt. In his talk, he encourages an integrated approach in order to have full control of the many processes of additive manufacturing.

About the Manufacturing Technology Centre

The MTC is a membership organization with over 100 members, including Concept Laser and Renishaw. The organization also has academic partners in the University of Birmingham, Loughborough University, and the University of Nottingham.

When the MTC opened in 2010, Wimpenny explained it had just five employees, now it has over 500 and a turnover of over €50 million.

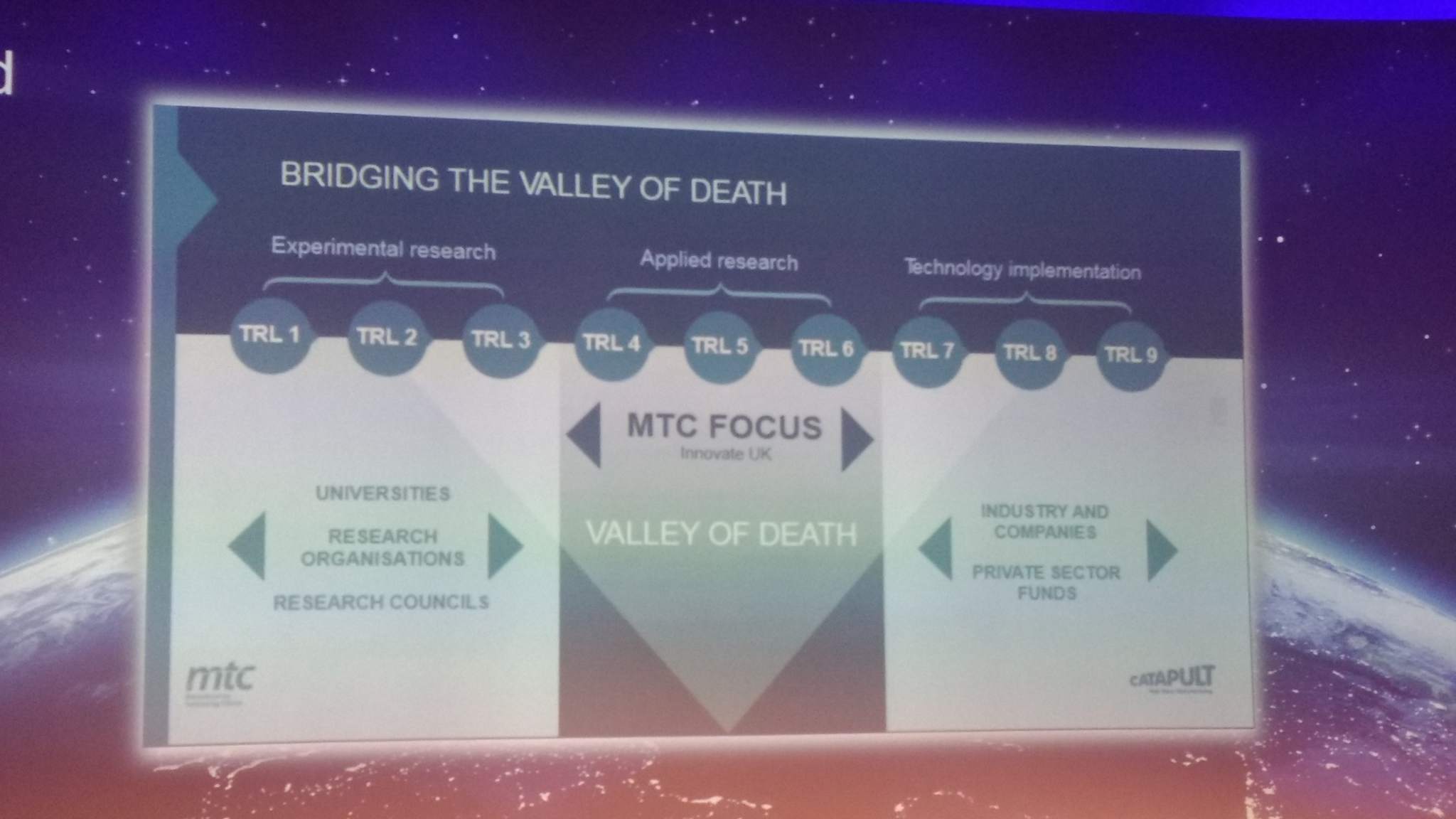

David Wimpenny cites the Fraunhofer model as inspiration, with MTC working with research institutions as well as companies within the industry. By doing so, they aim to bridge the gap between research in the field and its industrial application. Or more dramatically, “Bridging the valley of death.”

They created the National Centre for Additive Manufacturing two years ago, as a visualization of how they expect an additive manufacturing ‘factory of the future’ would look. However, Wimpenny is keen to stress it is not about the number of parts produced in the factory, but about control of the processes. Control of the quality and control of the data is the most important consideration for Wimpenny. As he says,

In a process chain, whatever you don’t control will be a problem

At the moment, for some critical applications, they have to CT scan every part they produce which drives up the cost of production. To address this, they have spent millions of dollars on a powder test lab in order to test the quality of the powders they use. This gives them better control in their research and more consistency in the parts produced.

Also at the conference is Dr.-Ing. Wilhelm Meiners who spoke about the influence of lasers in scaling productivity for series production using additive manufacturing.

Vote now in the 1st Annual 3D Printing Industry Awards. For the latest from the Additive World conference sign up to our newsletter and follow us on twitter.

Featured image shows the inside of the Manufacturing Technology Centre. Photo via MTC.