The University of Nottingham are researching the use of additive manufacturing in the automotive industry. The project is called Functional Lattices for Automotive Components (FLAC). The objective is to use 3D printing to create more fuel efficient auto mobiles while also improving their performance.

The project has been funded by a £368,286 ($452,918) grant from Innovate UK. The British government’s innovation agency which backs projects that use advanced technology like additive manufacturing. Recently, Innovate UK have funded projects including the 1000mph Bloodhound supersonic car and have also just announced they will be funding British companies who are incorporating 3D designing into their businesses.

The FLAC project will be a three-year long process and thus will likely be relocating its work to Nottingham’s new Institute for Advanced Manufacturing building when it completes construction at the end of this year.

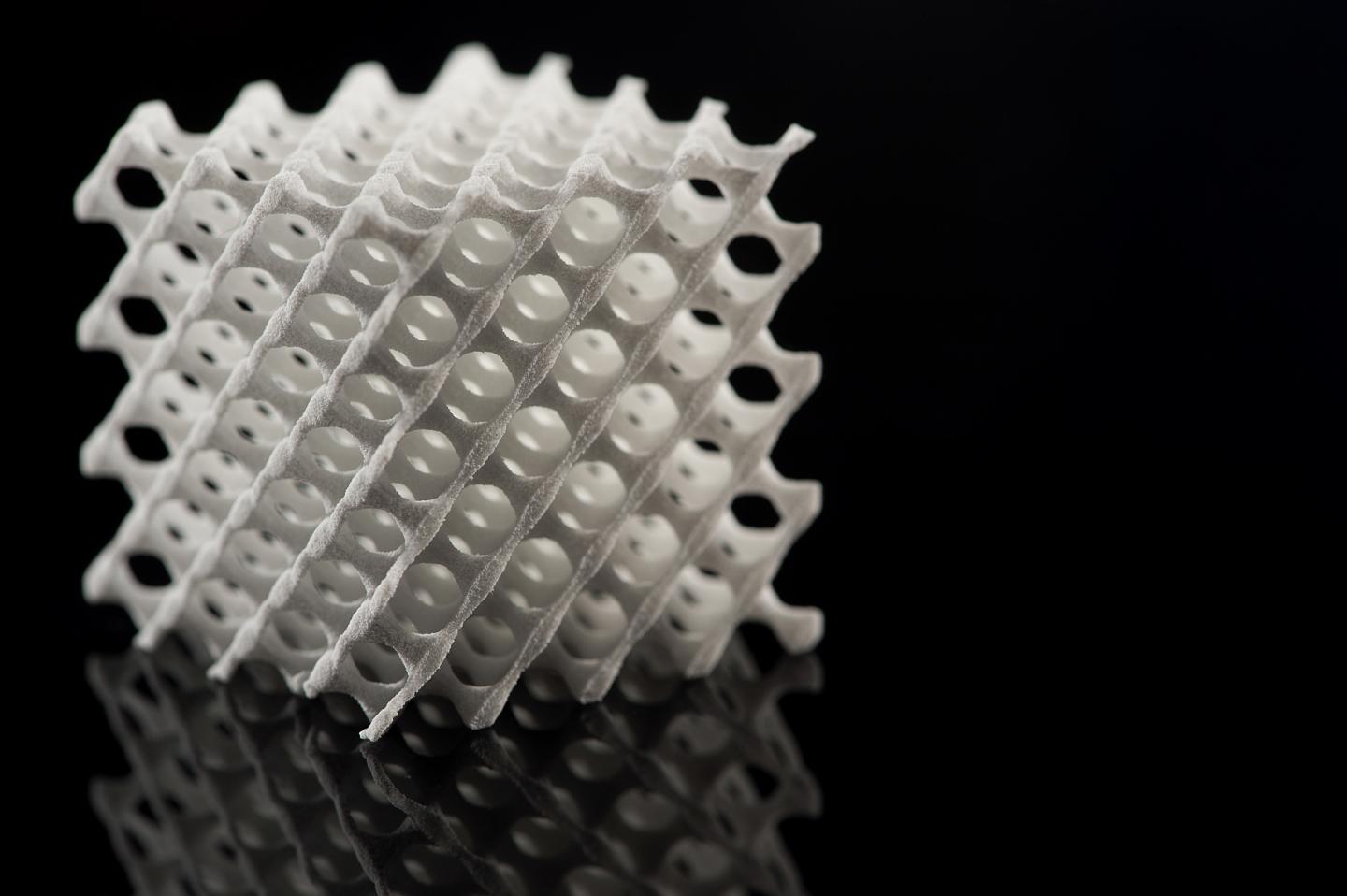

Engineers on the FLAC project will be using Selective Laser Melting (SLM) which is also known as Direct Metal Laser Sintering (DMLS). By using this technique, they will be able to create complex metal lattice structures that provide strength yet reduce weight with less density. This, in comparison with traditional techniques, is beneficial as it will reduce waste with less materials used and the reduction in the need for milling.

Through advancing individual components such as “brake calipers, heat sinks for LED headlights and power train sub-systems,” the FLAC project will aim to reduce weight in car parts by 40-80%. This is important as the automotive industry continues to implement carbon reducing strategies.

FLAC project lead, Professor Chris Tuck from the Additive Manufacturing and 3D Printing Research Group, explains how this will affect UK businesses,

FLAC will benefit UK automotive companies, increasing their competitiveness by allowing them to adopt innovative routes for the design and manufacture of lightweight on-vehicle componentry, with shorter lead times and lower costs than are presently available.

Increased performance

Not only will additive manufacturing reduce weight through the parts created, it also creates new possibilities to increase performance of parts in comparison to traditional subtractive manufacturing processes. Allowing for components to be produced with extra complexities such as hollow ducts that increase airflow. This would not be possible with traditional techniques that rely upon milling blocks of metal. By adding the components in layers, the process is able to introduce complex lattice structures.

Results of the project

The University of Nottingham explains that immediate benefactors of the FLAC project will be in the luxury car market and in advanced motorsport. In the future such techniques, as they advance and become more cost-effective, will be incorporated on a larger scale. The UK car manufacturing industry is particularly important as Professor Chris Tuck explains,

The automotive sector is one of the UK’s leading export sectors by value, representing around 6.3 per cent of all UK exports. Successful delivery of FLAC’s portfolio will enhance the R&D leadership in the key automotive technologies, and strengthen the UK automotive supply chain, resulting in increased revenues to the UK economy and government.

Sign up to our newsletter to receive up to date 3D printing news.

Featured image shows An example of a triply periodic minimal surface lattice structure developed during the FLAC project. Image via The University of Nottingham.