Through 3 rounds of funding, Innovate UK will share £3 million with companies incorporating design into the early stages of their projects. The fund’s first round, offering £1 millon, runs through January and February 2017 and could be the perfect opportunity for UK-based businesses to integrate 3D printing into their processes.

Who are Innovate UK?

Innovate UK is an agency created to inspire the implementation of science and new technologies in companies. The agency occupies a similar space to the additive manufacturing focused program America Makes and will publish a roadmap for 3D printing later this year.

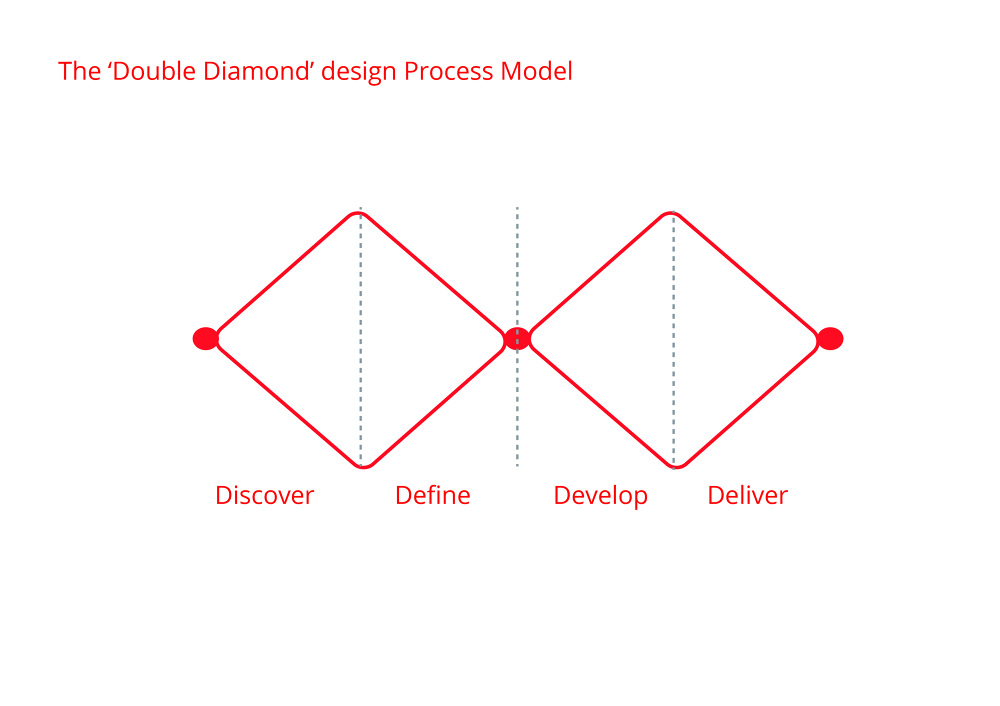

The Design Foundations competition aims are to ‘stimulate high-quality, human-centred design activities at the earliest stages of the innovation journey.’ The brief specifies that projects must comply with the ‘double diamond’ design process model.

Double diamond design

The double diamond model is a diagram illustrating the four key stages of a design process and how they inform each other. It was created by the British Design Council in 2005 to aid businesses in the pursuit of innovation.

Projects applying to the Innovate UK competition can be up to the ‘Develop’ stage of the process, with the fund helping them to achieve final delivery of their idea and continue the design cycle.

The British Design Council also support the fund with findings that show every £1 invested in early-stage design, i.e. Discover, Define and Develop, can return £20 to the business employing these techniques.

3D printing application examples

In an interview with 3D Printing Industry editor-in-chief Michael Petch Innovate UK lead manufacturing technologist Robin Wilson explains the integration of design for production. Drawing on his experience from an earlier position at automotive manufacturer Land Rover, Wilson explains:

…we CAD modeled the whole car and how it would be put together in real time to not only get the product design right but the manufacturing environment could also be developed in parallel.

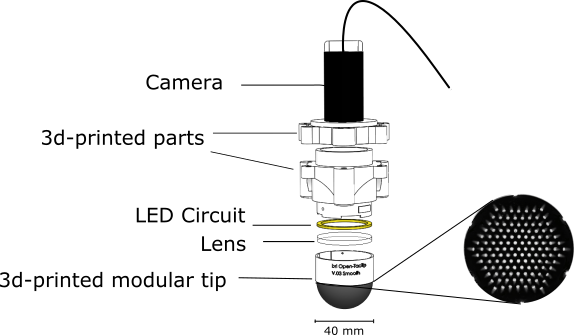

Bringing ideas to life through design, the University of Bristol, UK, has 3D printed a fingertip for robots. Known as the TacTip, this sensor can be installed into industrial machine and robot hands enabling them to process objects by touch.

The TacTip project fulfils innovative design needs through identifying a specific need in the market, and providing a low-cost solution that lasts.

Design can also fulfil human needs through the creation of bespoke products.

Jackson Gordon’s bionic arm is based on the customer’s brief to create a functional prosthesis inspired by the Metal Gear Solid 5 video-game. Throughout the process Gordon tested his CAD models of the hand by 3D printing them. The way the pieces fitted together, and performed in certain tasks, was redesigned in CAD software, and translated into the next prototype.

Theoretically, Gordon’s company Armatus Designs could use such a fund as this from Innovate UK to realise more bespoke designs, and make them commercially available.

The Phantom Pain Functional Prosthetic Hand Clip via: Armatus Designs on YouTube

A full brief and guidelines for Innovate UK’s first £1million Design Foundations competition can be found here. Deadline for registration is 22 February 2017.

The 3D Printing Industry Awards for innovation are now open for nominations.

Featured image shows ‘Suddenly there was a new idea’ Innovate UK stand at New Scientist Live conference 2016. Photo via: Innovate UK on Facebook