Metal 3D printing company Seurat Technologies has qualified 6K Additive’s 316L stainless steel powder for use on Seurat’s Area Printing platform, to enhance sustainability in the additive manufacturing sector.

Seurat Technologies’ pilot factory in Greater Boston is set to operate solely on clean energy, aiming to produce over 25 tons of metal parts each year. Meanwhile, 6K Additive stands out for its notably lower energy consumption and reduced carbon emissions in manufacturing. According to the company, this achievement is attributed to its use of sustainable feedstock sources, implementation of a highly efficient microwave plasma process, and delivery of yields exceeding 90%. Compared to conventional atomization methods, 6K Additive’s approach demonstrates a substantial reduction in environmental impact.

“Our ability to leverage machining scrap, used powders, and other revert feedstock for a wide variety of metal powders sets us apart from any other powder supplier in the industry with regard to sustainability. Backed by the efficiency of our UniMelt process, it’s clear why 6K Additive is considered a leader in sustainable powder production for AM,” said, Nick Pflugh, Chief Commercial Officer for 6K Additive. “Customers now have a very compelling reason to work with Seurat for part production, powered by the world’s most sustainably sourced powder from 6K Additive.”

6K Additive’s contributions to eco-friendly additive manufacturing

Seurat utilizes 100% green energy to innovate and localize manufacturing with its Area Printing technology, developed at Lawrence Livermore National Laboratory. This metal AM technology facilitates high-precision, high-volume, and decarbonized manufacturing processes. Seurat estimates that its implementation could directly mitigate up to 100 million tons of CO2 by 2030.

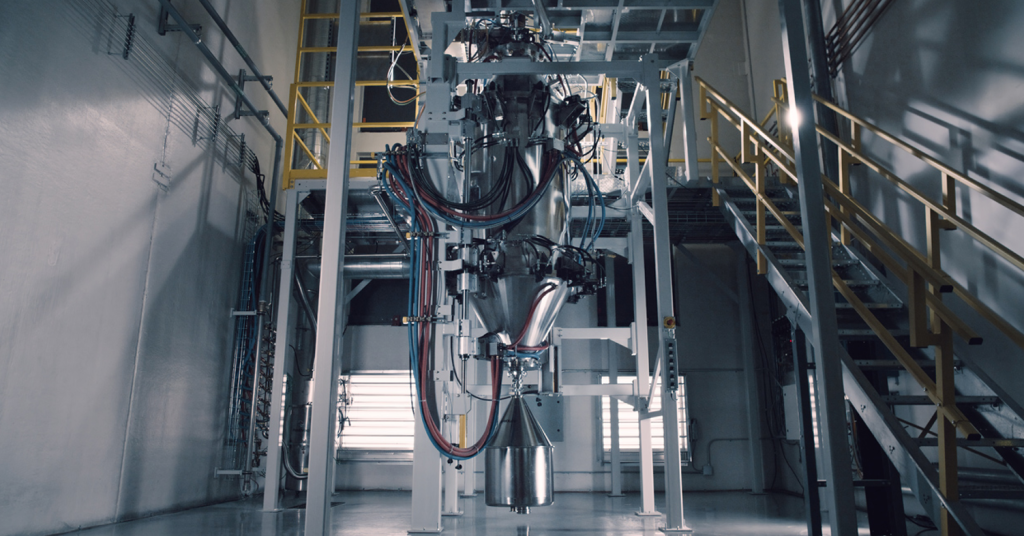

6K Additive’s product portfolio includes a range of premium powders, such as nickel, titanium, copper, stainless steel, aluminum alloys, and refractory metals like tungsten, niobium, and rhenium. The company’s proprietary UniMelt system is highlighted for its unique capabilities, including precise plasma control, minimal contamination, superior performance, and high production throughput.

Back in 2023, 6K Additive and Fraunhofer ILT collaborated on a life cycle assessment (LCA) for additive manufacturing, aiming to clarify its environmental impact. Utilizing sustainably produced Ni718 powder from 6K Additive, the study assessed carbon emissions from material through post-processing on a laser powder bed fusion (LPBF) machine.

Early findings presented at Formnext 2022 revealed significant reductions in energy and carbon emissions with 6K’s UniMelt platform. The study emphasized the importance of evaluating the entire additive manufacturing process for sustainability, addressing market demands for carbon neutrality solutions.

“Our partnership with 6K Additive is beneficial for Seurat on several fronts,” added, Ben Fotovvati, Additive Manufacturing Process Engineer at Seurat Technologies. “Not only are we partnering with a supplier that can meet our powder quality requirements, but we are also teaming with a leader in sustainably sourced materials, which aligns perfectly with our decarbonization mission.”

A greener future within the AM sector

Sustainability is paramount in the 3D printing sector to mitigate environmental impact, conserve resources, and foster a more responsible approach to manufacturing. As the industry continues to evolve, integrating sustainable practices will be essential for its long-term viability and growth. This year alone saw two entities aiming to increase the sustainability of AM processes.

Supported by the National Manufacturing Institute Scotland (NMIS) with £1 million, the AM-BATS project aids over 100 Scottish SMEs in adopting industrial additive manufacturing. NMIS has guided firms across sectors to integrate 3D printing, aiming to unlock new opportunities and fostering a shift towards sustainable manufacturing in Scotland’s industries.

Over three years, NMIS assists in feasibility assessments, provides training, and evaluates sustainability benefits. The initiative, aiding 36 ventures, spans industries like EVs, food, sports, and medicine. Companies leverage additive manufacturing for enhanced products, citing faster development, sustainability, and efficiency. Examples include medical devices by Confidence Plus and eco-friendly fashion by ROCIO.

At the beginning of the year, the winners of the Environmental Additive Research for Tomorrow’s Habitat (EARTH) project received a $1.2 million grant from America Makes. Conducted in partnership with the National Center for Defense Manufacturing and Machining (NCDMM), this project focuses on advancing sustainable additive manufacturing practices, particularly in terms of recycling and reutilization of 3D printing materials. Selected to advance this mission, the winning projects will utilize the funding to explore and validate additive manufacturing designs and materials that align with sustainability criteria.

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 6K’s UniMelt plasma production system is uniquely capable of converting high-value metal scrap of numerous forms into high-performance metal powders for additive manufacturing. Photo via 6K Additive.