Metal 3D printing start-up Seurat Technologies has raised $41 million in a Series B funding round led by investment firm Capricorn’s Technology Impact Fund (TIF).

Using its newfound capital, the firm aims to accelerate the R&D and commercialization of its Area Printing process, which uses two million laser points to enable the mass production of end-use-quality parts. According to Seurat, its “groundbreaking” technology is “infinitely scalable,” and potentially offers cost savings compared to traditional die-casting processes for manufacturers operating in “all industries.”

“Seurat is bringing to market a completely revolutionary technology. Think evolving from writing a letter to the advent of the printing press, but with lasers printing metal parts.” said James DeMuth, CEO and Co-Founder of Seurat Technologies. “Bringing on new financial and strategic investors at the caliber of Capricorn will greatly aid Seurat in taking the big next step forward towards commercialization.”

Seurat Technologies’ slow-burner

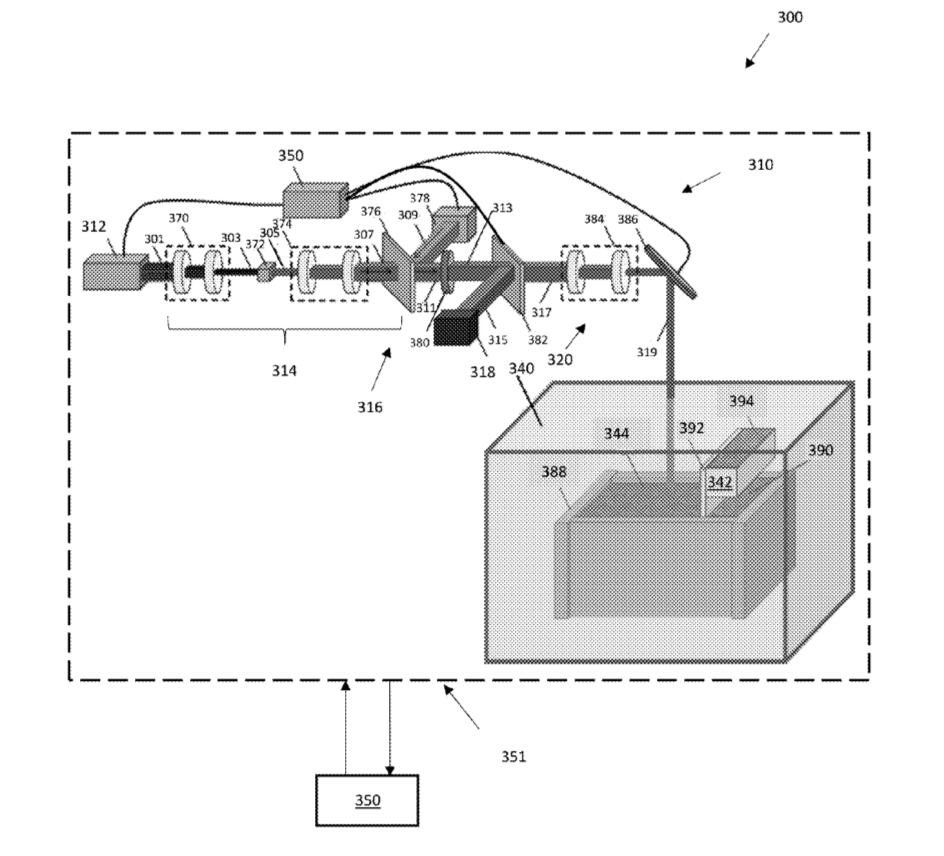

Since being founded in 2015, Seurat Technologies has iteratively developed its proprietary Area Printing process, with the intention of marketing it to automotive, consumer tech and industrial clientele. Compared to existing technologies, Area Printing’s ‘USP’ is that it involves focusing more than two million points of laser light onto a metal powder bed, which can be fine-tuned to rapidly create end-use parts.

Within the automotive sector, the company sees potential applications for its technology in producing on-demand spares and prototyping components for next-gen electric vehicles, while it believes that the inherent scalability and spatter-free nature of its process also make it ideal for producing large-format parts with industrial applications.

Thanks to the high throughput of Seurat Technologies’ technology, users effectively stand to benefit from a lower cost per part, and the firm says that its first-gen system is 50% cheaper to run than current machines. In fact, the company is targeting further efficiency gains moving forwards, and it anticipates that its Area Printer will become more affordable to manufacture with than die casting by 2030.

However, the company’s process has been under development for at least six years, and since it was granted a patent back in 2017, the firm’s commercial offering has yet to materialize. Given the ‘novel energy-recycling element’ outlined in this patent, and the eco-friendly focus of its new investors, Seurat Technologies will be hoping that it now has the backing needed to finally bring its technology to market.

Edging towards marketability

Seurat Technologies’ latest round of funding follows a $13.5 million Series A investment made by True Ventures in January 2018, and takes its total raised to over $57.9 million. The additional funding is set to be deployed as a means of advancing the company’s proprietary technology, and helping accelerate the process of bringing it to market.

The investment has been provided as part of Capricorn’s wider TIF initiative, and Seurat Technologies’ CEO James DeMuth has already hailed the program’s potential in expediting its product commercialization. In essence, TIF is a VC partnership that invests in those tech firms developing novel materials, devices, systems and business models.

Already, the program has seen Capricorn provide backing to sustainability and renewable energy-focused firms such as Saildrone and Helion Energy, and in the past, the company has also been an early supporter of the likes of Tesla and SpaceX, potentially making it an ideal partner to help Seurat Technologies launch its first products and scale thereafter.

“Capricorn invests in fast-growing companies with superior management teams that are fundamentally transforming industries,” said Ion Yadigaroglu, Partner of the Technology Impact Fund and Capricorn Investment Group. “Seurat is clearly a disruptor in the AM space, offering a powerful Area Printing technology platform that creates significant value to the entire manufacturing sector.”

In addition to funding from Capricorn, Seurat Technologies has also received investment from the $44.6 billion global mobility supplier DENSO, as well as continued support from long-term backers True Ventures, GM Ventures, Porsche Automobil Holding SE, Siemens Energy and Maniv Mobility.

“Working with Seurat advances DENSO’s Industry 4.0 journey and keeps us at the forefront of manufacturing technology,” said Tony Cannestra, Director of Corporate Ventures at DENSO. “It also supports our broader investment strategy, which focuses on collaborations that speed innovation, help meet customer needs and get us closer to a greener, safer, more seamless mobility future.”

Metal 3D printing at scale

While it remains difficult to assess Area Printing’s end-use capabilities, Seurat Technologies is hardly the first company to set its sights on high-throughput metal 3D printing. SLM Solutions launched its powerful NXG XII 600 3D printer at Formnext Connect, featuring twelve simultaneously operable 1 KW lasers, which enable mass part production.

In terms of Powder Bed Fusion (PBF) systems, Chinese 3D printer manufacturer Farsoon Technologies released a new power-oriented machine at the TCT Asia 2021 trade show. Designed to allow industrial adopters to “scale up metal production,” the company’s ‘FS721M-8’ 3D printer packs eight 1000W lasers and an impressive 720 x 420 x 420mm build volume.

Elsewhere, Sciaky has revealed that last year its Electron Beam Additive Manufacturing (EBAM) systems achieved their highest throughput to date, depositing over 12,000 lbs of titanium. The firm says that the High Deposition Rate (HDR) of its machines and demand from aerospace and defense clients, allowed it to reach the new milestone.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a Seurat Technologies metal 3D printed part. Image via Seurat Technologies.