3D printer manufacturer Stratasys has launched its new Selective Absorption Fusion (SAF) HighDef Printing capabilities and the launch of the H350 printer, Version 1.5 (V.1.5).

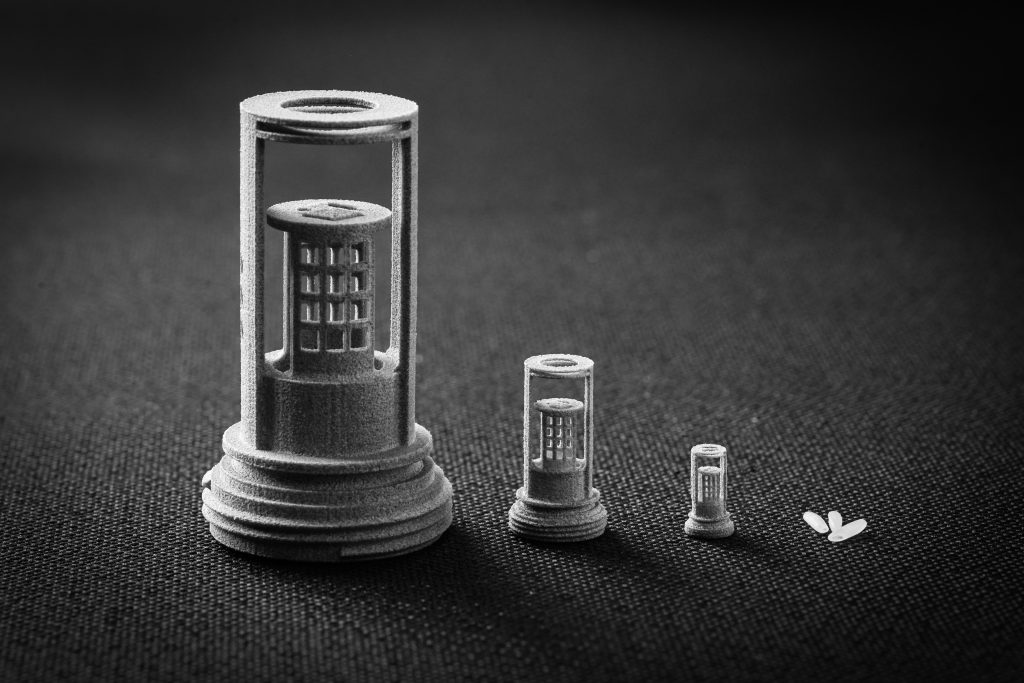

According to the company, the HighDef Printing capabilities promise to deliver more precise and detailed prints, catering to industries like aerospace, automotive, and healthcare. This advancement enables manufacturers to produce intricate parts with smoother features, such as gears and mechanisms while ensuring reliable repeatability. The integration of SAF thermal control further enhances the versatility of additive manufacturing, suitable for various design possibilities.

“High-definition printing enables tighter tolerances, moving assemblies and a new range of applications for SAF customers,” said Adam Ellis, Corporate Applications Manager, Stratasys. “Bringing HighDef to our customers will help us expand and improve their capabilities and increase their adoption of 3D printing in manufacturing roles.”

Stratasys SAF technology

Introduced in 2021, and developed by Xaar, SAF technology selectively applies an infrared-sensitive binder onto polymer powder, fused with an infrared lamp. This ensures consistent part quality and mitigates warping. The Big Wave powder management system as stated by Stratasys, optimizes powder distribution, reducing waste and operational costs. Ideal for tooling and high-volume production, SAF offers high throughput and exceptional part properties across various polymer powders.

Stratasys’ unveiling of new products seeks to expand SAF technology adoption across diverse manufacturing sectors by providing enhanced functionalities and broader applications. Through a firmware update, the integration of HighDef Printing capabilities ensures compatibility with previous H350 printer models without additional costs for customers. This strategic move highlights Stratasys’ dedication to delivering value-added solutions while maximizing existing infrastructure utilization for its clientele.

Alongside the introduction of HighDef Printing, Stratasys’ novel H350 V1.5 printer, features upgraded sensors and remote service capabilities to enhance operability and maintenance. Striving to meet customer demands and adapt to evolving performance criteria, Stratasys endeavors to equip manufacturers with efficient production scaling tools, maintaining speed and quality standards.

Commenting on the significance of these developments, Torben Lange, VP of SAF R&D at Stratasys, emphasized the alignment of the upgraded H350 and new capabilities with customers’ expressed needs. He highlighted the potential for exploring new applications and use cases, thereby facilitating the seamless integration of additive manufacturing into diverse production workflows.

Technical specifications of the H350 V.1.5 3D printer

| Printer Performance | |

| Effective build size (XYZ) | 315 x 208 x 293 mm; (12.40 x 8.18 x 11.53 in) |

| Effective build volume | 19.2 l (5.07 gallon) |

| Layer thickness | 100 μ (0.004 in) |

| Time to a full build | 11.62 hrs. |

| Power | |

| Requirements | 400VAC, 3P+N+PE, 50/60 Hz, 16A |

| Consumption | 3.25 kW, 5 kW (peak), 0.15 kW (Idle) |

| Operating conditions | |

| Temperature | 20-25˚C (68-77 deg F) |

| Humidity | [40-55]% RH |

| Extraction rate | 300m3/h (177 CFM) with adjustable damper |

| Dimensions (W x D x H) | |

| Printer | 1900 x 940 x 1730 mm; (74.8 x 37.0 x 68.1 in) |

| Printer crate | 2156 x 1196 x 2100 mm; (84.9 x 47.1 x 82.7 in) |

| Weight | |

| Printer | 825 kg (1819 lb) |

| Crated printer | 950 kg (2094 lb) |

| Connectivity | |

| Network requirements | RJ45 Ethernet connection 35MBit, Network with DHCP server and internet access |

| Software | |

| Supported software workflow | GrabCAD Print, GrabCAD Print Pro, GrabCAD Print Server, Materialise Magics, Siemens NX, and PTC Creo |

| Certificates | |

| Safety | EN ISO 12100:2010 |

| Electromagnetic | DIRECTIVE 2014/30/EU |

| Environmental | REACH, RoHS, WEEE, Modern Slavery Act, CoA, CoC (and from 2021, Conflict Minerals regulation), TSCA |

| Materials | |

| Powders | Stratasys High Yield PA11, SAF PA12 |

| Fluid | Stratasys HAF (high absorption fluid) |

| Warranty and Service | |

| Warranty | 1-year limited warranty (warranty includes print heads and consumables*) |

| Service | Service plans include print heads and consumables* |

Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows Stratasys’ new HighDef Printing capabilities are designed to allow for more exact, high-definition printing with detailed resolution. Image via Stratasys.