The British engineered Bloodhound car is set to break the land speed record next year in 2017 and following the conclusion of the F1 season at the weekend, we thought we would take a look at other engineering projects that are being developed with 3D printing.

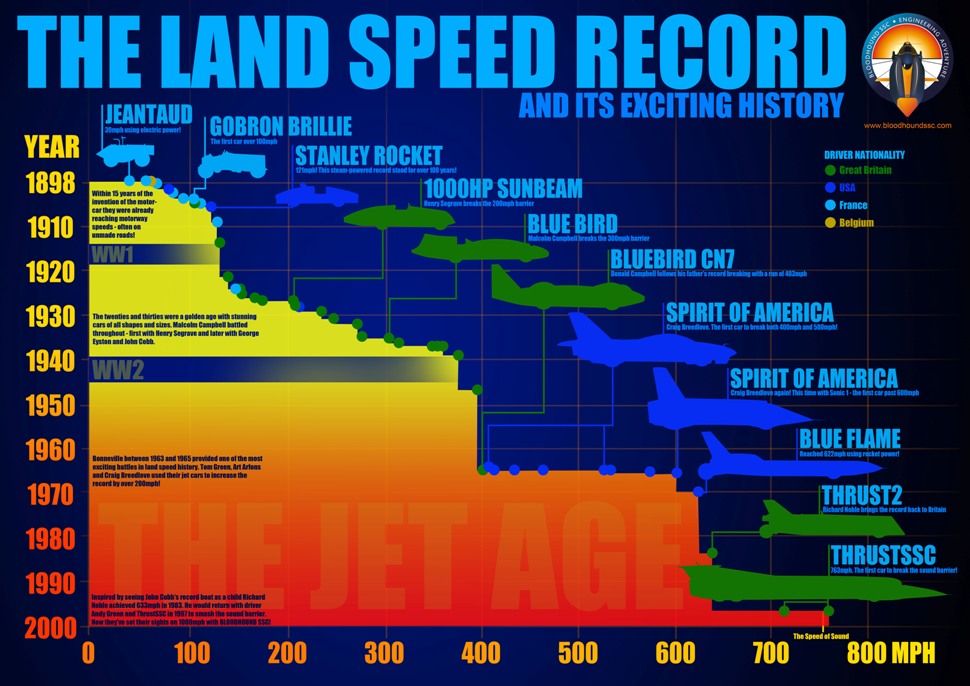

Bloodhound SSC are attempting to beat the current land speed record which stands at 763 mph and is held by Thrust SSC. Thrust being another UK team led by Bloodhound’s Project Director Richard Noble and driven by Andy Green. Using 3D scanning and Computer Aided Design, the Bloodhound SSC will attempt to break the 1000mph barrier next year in 2017. It has recently been announced that Zhejiang Geely Holding Group (ZGH) have decided to invest in the project meaning the Bloodhound takes a step closer to the starting grid. While ZGH are the owners of Volvo and the London Taxi Company don’t expect rocket powered taxis any time soon, at least not until London has been cleared of all its stones and turned to desert.

The Track

The team behind Bloodhound scoured the earth to find the perfect track for the record attempt, focusing on desert that was perfectly flat. The track needed to be at least 12 miles long and 2 miles wide. The chosen destination is Hakskeen Pan, South Africa. The Bloodhound SSC project has become a showcase for engineering capability, pushing the boundaries of science with nearly 300 companies getting involved with the project. The desert, 22 million square metres, in South Africa was recently cleared of 15,800 tonnes of stones by a dedicated team of 317 members of the local community.

The Power

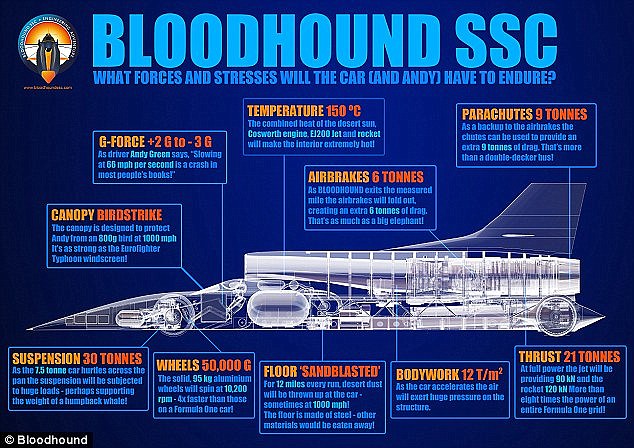

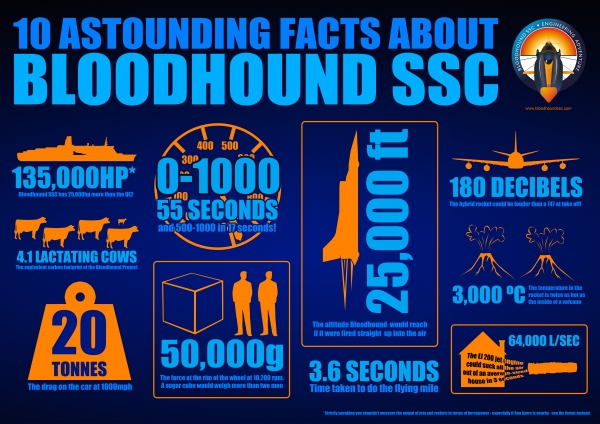

The Bloodhound has three sources of power: a Rolls-Royce EJ200 jet engine, a cluster of Nammo hybrid rockets, and a 550bhp Supercharged Jaguar V8 engine. Combined, these generate 135,000 thrust horsepower which is the equivalent to 180 Formula One cars. This immense power allows the Bloodhound to reach 1,000mph in just 55 seconds and then return back to zero in another 65 seconds, covering 12 miles in the process. The EJ200 jet engine consumes 65,000 liters of air a second, this is the equivalent of sucking the air out of an average house in only three seconds. The rate at which the Bloodhound will decelerate from 1000mph would be the equivalent to slowing from 60mph to a stop in just one second.

3D printing and scanning

To reach these impressive statistics and figures, Bloodhound SSC harness additive manufacturing. For example, creating the steering wheel to perfectly fit driver Andy Green’s hand meant 3D scanning and printing was vital. Upon creating the prototype in plastic with 3D printing, the team created the final form in metal. As the steering wheel needs to withstand significant forces they turned to titanium. The 3D printed steering wheel will not just be for prototyping but actually used in order to break the land speed record. The nose cone and air brake door hinges, which “must be able to withstand 50kN of force transferred from the door itself,” are also 3D printed. The Air Brake is critical to stopping the vehicle. Renishaw have been trusted with these 3D printing tasks as 3DPI reported back in 2013.

The Bloodhound SSC is part of The LIGHT project funded by Innovate UK. The projects complete title is Inspiring New Design Freedoms and Light-Weight Solutions for Metal Additive Manufacturing and also involves Delcam Ltd, HiETA Technologies Ltd, CRDM/3DSystems Ltd, EOS Electro Optical Systems Ltd, Simpleware Ltd and Magna Parva Ltd. The project is certainly a great showcase for engineering talent and the world will be watching when next years record attempt takes place.

Featured Image shows visualization of the Bloodhound during it’s run. Image via Bloodhound SSC.