Biological and chemical researchers are developing 3D printable inks capable of self-assembly, i.e. forming a shape based on a reaction within itself.

In this article, 3D Printing Industry examines two papers exploring 3D printing for self-assembling inks. First the 3D cell bioprinting of self-assembling peptide-based hydrogels from researchers at the University of Manchester, UK. And second, 3D printing of self-assembling thermoresponsive nanoemulsions into hierarchical mesostructured hydrogels from the Massachusetts Institute of Technology (MIT).

In the first instance, hydrogels are embedded with stem cells that self-assemble into their 3D printed shape.

In the second, a new type of ink for vat polymerisation is explored, self-assembling through a reaction to heat.

University of Manchester hydrogels

There are two possible approaches to tissue engineering: designing from the ‘top down’, or the ‘bottom up’. The use of 3D printing is explored in both approaches.

When tissue engineering is conducted from the top down, a 3D printed scaffold is coated in cells to form a tissue-like shape, as for example in the graphene scaffolds developed by Case Western Reserve University (CWRU) in Cleveland, Ohio.

Conversely, in the bottom up approach cells are encapsulated within a material that mimics natural tissue and can then be left to culture. The mimicking material is typically a hydrogel, which is water-based and jelly-like. This is the method explored by the University of Manchester.

Possibilities for breast cancer research

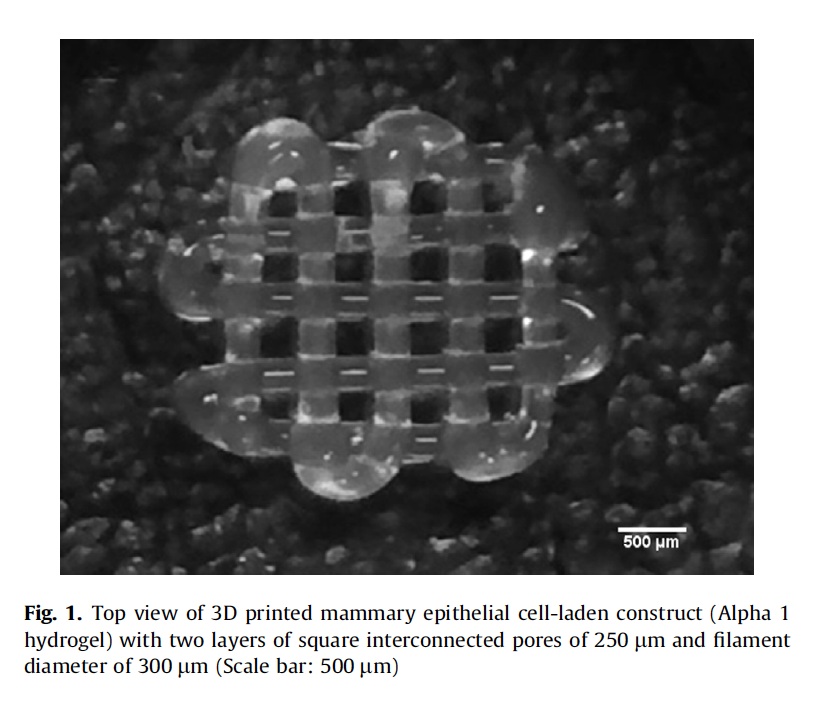

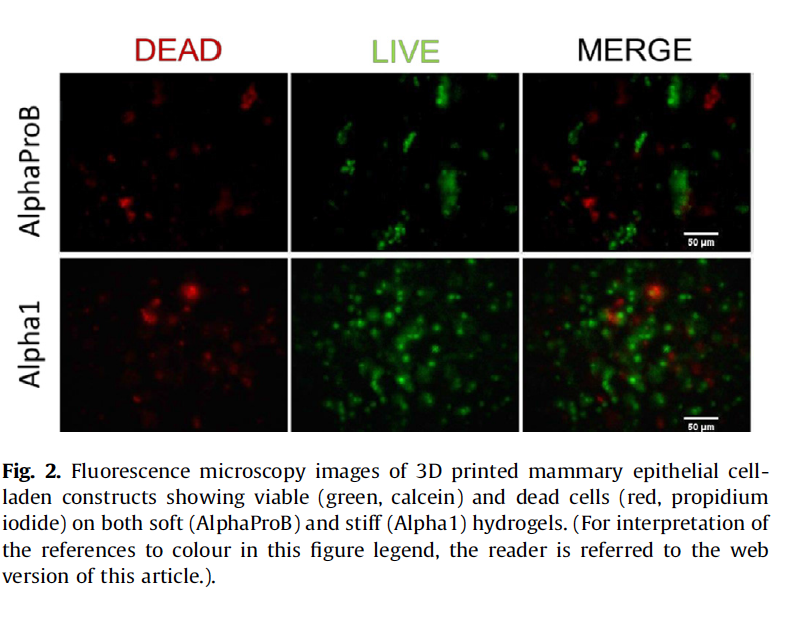

In order to be comparable to natural tissue 3D printed materials need to retain a complex structure, the right balance of softness versus rigidity, and be able to encourage cell growth and spreading.

The material chosen by Domingos et al. and the Univeristy of Manchester is a peptide-based hydrogel, formed of amino acids. The amino acids in peptides are composed of carbon, hydrogen, oxygen, and nitrogen which are essential to the body’s ability to process substances within the body.

The conclusions of the study find that the peptide-based hydrogel is able to support cell proliferation after 7 days of culture. This means the cells are able to self-assemble or ‘sort-out’ into the shape they would naturally adopt within the body. The successful culture of the mammary epithelial cells in this instance, also give scope to using the method for breast cancer research.

The 3D printing process of a cell-laden peptide hydrogel is an improvement on ‘top down’ approaches in two ways. Firstly, it doesn’t damage valuable stem-cells with high-temperatures or radiation. And secondly, it is a more direct approach. 3D printing cells within the structure of a hydrogel cuts out the further steps required in first 3D printing a scaffold, and then coating it in cells.

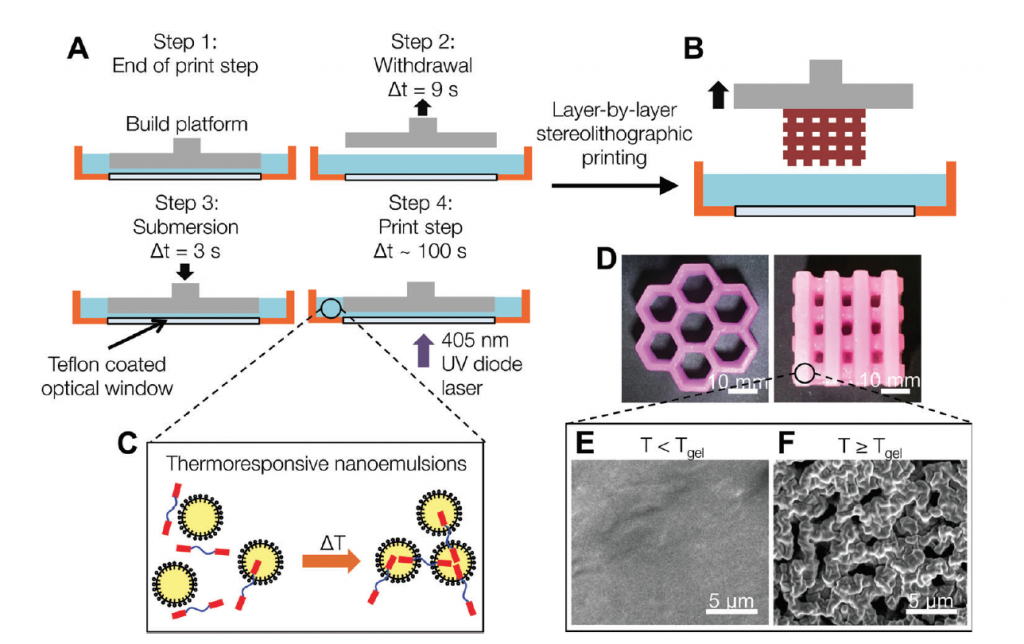

Heat sensitive MIT structures

Where the University of Manchester’s research takes the FFF layering approach to their 3D printed hydrogel, MIT looks at a photosensitive ink, 3D printable through the SLA vat polymerisation method. Heat-sensitivity is how the inks self-assemble to form a desired structure.

In this technique, nanoemulsions are used, which are sub-millimetre droplets composed of water and oil. As they are oil-based, the nanoemulsions repel water and as such are capable of being manipulated to control it. Adding them to 3D structures can recreate ‘veins’ within the structures, that can be used to mimic the functionality of blood vessels, or to secrete medication in a controlled manner.

The aims of this technique are similar to research conducted by Columbia University, who have created a hydrogel based clock-like mechanism that also releases drugs into the body. The research at Columbia University however relies on magnets to control the secretion of drugs, whereas the nanoemulsions gives MIT’s technique a microfluidic approach.

Science imitates nature

3D printing materials gives the precision control necessary to copy the complex shapes of cells found in living organisms. Developing self-assembling inks then encourages these cells to proliferate in a more natural way. Combining the two approaches gives a more faithful-to-life representation of cells within the body, enabling more accurate scientific research and understanding of the human body.

Featured image shows Ink in water by Lee Royal on Flickr