3D Printing Industry will be flying to Eindhoven next week to cover the Additive World ‘Industrial 3D printing’ conference and get a live demonstration of the MetalFAB1 machine from Additive Industries.

Taking place during the 15-16th March, the first day will be dedicated to discussions regarding additive manufacturing and its applications at the High Tech Campus. While the second day will focus on the MetalFAB1 industrial 3D printer at Additive Industries’ base in Strijp-S.

Additive World will feature talks from leading companies in the 3D printing industry. Speakers include Tom van ‘t Erve of Siemens Industry Software, Dr.-Ing. Wilhelm Meiners of Fraunhofer ILT research group Rapid Manufacturing, Ludo Bautmans of Oerlikon and many more.

Additive World Schedule

The first day of the conference will revolve around a discussion on how to optimize additive manufacturing for industrial use. Talks during the day will cover design for additive manufacturing, materials, equipment, post processing and business cases. During the Additive World Awards dinner in the evening, the winners of the Additive World Design for Additive Manufacturing Challenge 2017 will be announced.

The second day of the conference will focus on Additive Industries’ MetalFAB1 metal 3D printer, and will also include talks from the company. During the day Additive Industries will “open their doors and share ‘what’s cooking in their Labs.’”

MetalFAB1

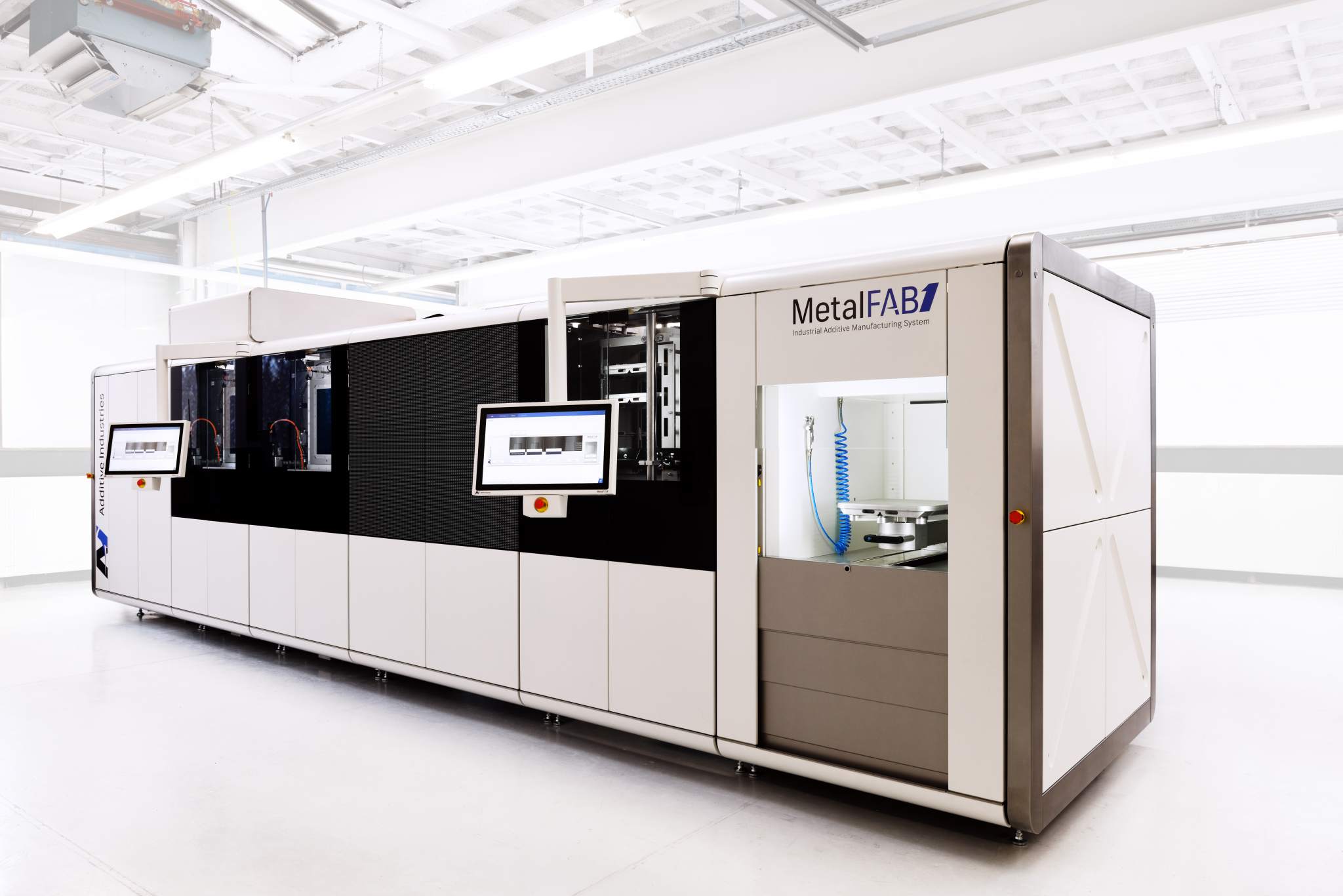

The MetalFAB1 was first unveiled in 2015 and is regarded by the company as “the first industrial metal 3D printing system for series production.” Encapsulating both metal 3D printing and post-processing methods, the system is designed to provide a single solution for creating metal parts. Using multiple lasers in its powder bed fusion approach, the machine also houses “heat treatment, automated build plate handling and storage.”

Reproducibility and predictability

The main focuses of the machine are reproducibility and predictability. Reproducibility is, “assured by a solid machine design in combination with a smart calibration strategy.” The company also state that predictability is enabled by, “combining simulation and in-process quality controls with the core additive manufacturing process.”

As we reported at the recent Additive Manufacturing for Aerospace, Defense and Space conference, certification of 3D printed parts is a key concern for the industrialization of additive manufacturing. This is an area that the MetalFAB1 system hopes to address with its reproducibility and predictability.

The machine has a modular design meaning the system can be expanded further to increase its capabilities even more. Additive Industries describe their 3D printer as bringing “additive manufacturing, from lab to fab.” Airbus APWorks received the first MetalFAB1 last year and 3D Printing Industry are looking forward to getting another look at the machine.

Sign up to our newsletter to receive updates on news from the Additive World conference and make sure to follow us on social media for the very latest from the conference.

Featured image shows the High Tech Campus in Eindhoven where the conference will be held. Photo via High Tech Campus.