In this article looking at the future of 3D printing Eujin Pei and Giselle Loh, of Brunel University London, UK discuss how material properties and material behaviour can be controlled to support the integration of functions.

Functionally Graded Additive Manufacturing by Eujin Pei and Giselle Loh, Brunel University London, UK

Additive Manufacturing (AM), commonly known as 3D Printing has the ability to produce parts with freedom of geometry and enabling the operator to fully control the production process chain.

We predict that in five years ahead, the prospect of Functionally Graded Additive Manufacturing (FGAM) will enable us to focus on material-centric fabrication by highlighting the structure-property relationship.

This process is characterized by simultaneous synthesis and densification of three-dimensional objects that are driven by the pre-determined organisation of the deposited material as opposed to only its shape and form.

Why is Functionally Graded Additive Manufacturing important?

FGAM is an integrated design approach and a technological framework to model, analyze and fabricate components that are characterized by gradual variations in composition and structure over volume, corresponding with multiple and continuously varied functional constraints.

FGAM parts attain their multi-functional status from their property gradation, which can be achieved by mapping performance requirements and allocating the material structures throughout the 3D space.

FGAM establishes a radical shift from contour modelling (based on geometry and shape) to material-performance (based on functional parameters) modelling. The aim of FGAM is to fabricate performance-based geometrical components driven by their graduated properties and material behaviour to support the integration of functions.

The use of additive manufacturing to vary micro-structure

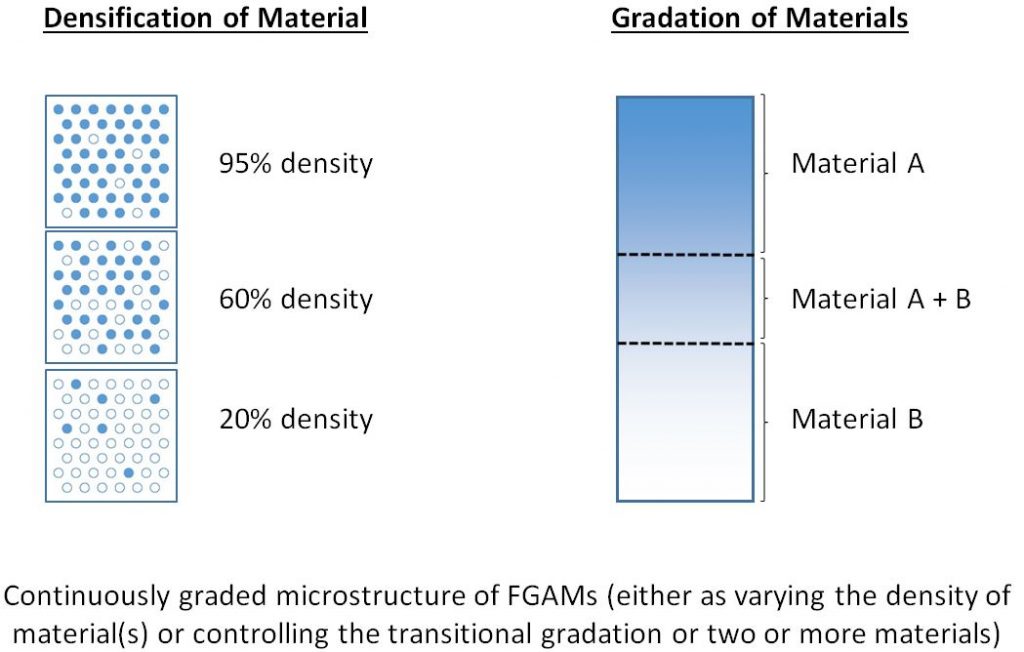

The use of FGAM can achieve properties such as varying the level of glass transition, density, elasticity and translucency. The differences in micro-structural phases contribute to different material properties within the singular component.

In short, Functionally Graded Additive Manufacturing (FGAM) is defined as a single Additive Manufacturing process that either uses the gradational mixing of materials or controlling the density of a material to fabricate freeform geometries with variable-properties within one component.

With respect to current Computer Aided Design (CAD), existing limitations lie in employing digital entities (programming, designing and simulation) that can accurately describe the micro-scale properties of materials and to generate the toolpaths for fabrication.

Current CAD tools employed for AM technologies have remained fairly traditional and no material information is taken into consideration in this intermediate file format.

For FGAM to take off, it will require a totally new approach of Computer-Aided Engineering (CAE) analysis that can specify, model and manage material information for Local Composition Control (LCC).

Eujin is the Programme Director for the BSc Product Design and BSc Product Design Engineering courses in Brunel Design. He is a Chartered Engineer (CEng) and a Chartered Technological Product Designer (CTPD). He chairs AMT/8 within the British Standards Institute (BSI) which publishes national standards for Additive Manufacturing.

Giselle Loh is PhD Researcher at Brunel University London. Giselle is currently researching functionally graded additive manufacturing and 4D printing.

A research paper with more information about Functionally Graded Additive Manufacturing is available here.

The authors are involved in investigating aspects of Functionally Graded Additive Manufacturing and joint PhD supervision, industry partnerships and collaborative research opportunities are very welcome. For more information, contact: [email protected]

Featured image shows the Redefining exhibition at the Design Museum London for Made in Brunel.