3D printing has returned to the cover of the Economist magazine. The first issue from July features several articles and a leader about additive manufacturing. This is not the first time 3D printing has been featured heavily by the magazine, however on this occasion 3D printing shares cover space with the President of the United States, Donald Trump.

Does the current issue suggest that wider market opinion about 3D printing has turned a corner after the over exuberance and excessive hype of 2014?

Scepticism looks less and less credible

The tone of the leader would suggest so. The headline is, “3D printers will change manufacturing” and accompanied by the subheading “Sceptics doubt the technology can be used for mass production. Just wait.”

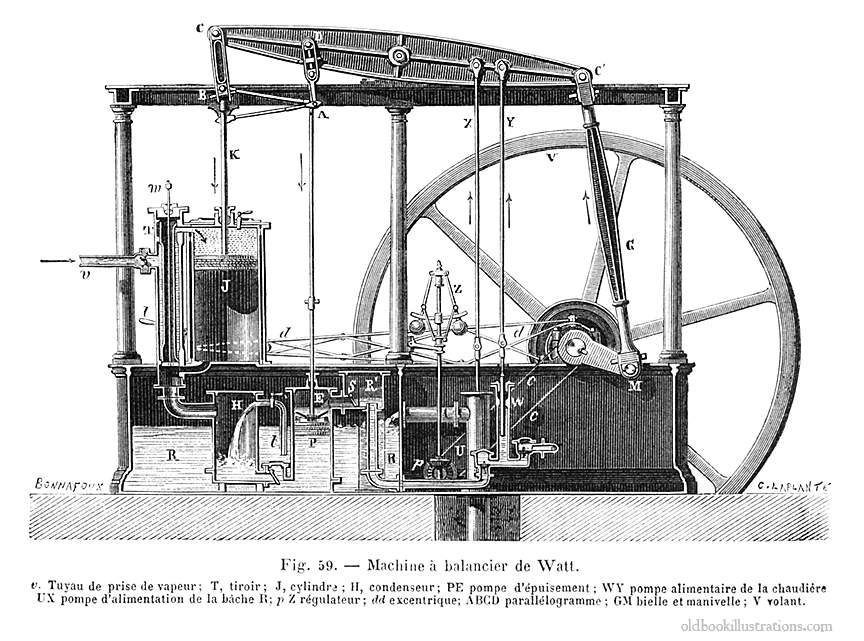

The writer draws comparisons between Taiichi Ohno’s Toyota Production System, Henry Ford’s production line and the flying shuttle, invented in 1733 by John Kay for the textile industry. The article makes the point that manufacturing advances take time to catch on.

The Economist points out that, “sceptics still rule the roost when it comes to goods made in high volumes. They say that 3D printers are too slow and too expensive.” However the article goes on to say, “Such scepticism looks less and less credible.”

Innovation and the advance of society

Although often seen as a conservative voice, the Economist has it’s origins in what might be considered radical by some. When the magazine was founded by James Wilson in 1843 it was to champion the classical Liberalism of John Stuart Mill.

Earlier editions focused on issues such as the restrictions that the patent system placed on technology and how it prevented innovation and the advance of society.

For example, as the first industrial revolution was beginning the Economist wrote frequent articles about this topic and the magazine still describes patents as, “a government-granted temporary monopoly.”

Industry needs to rethink the value of additive manufacturing

Other articles discussing 3D printing can also be found in this week’s Economist. “Making things anew 3D printing transforms the economics of manufacturing” describes how additive manufacturing abandons economies of scale. The article uses Domin Fluid Power, of Bristol in the United Kingdom who are making high-performance hydraulic pumps and powered servo-valves with an EOS metal 3D printer.

Marcus Pont, general manager at Domin, says, “Industry needs to rethink the value of additive manufacturing. It is not just a weight reducer but a cost reducer as far as we are concerned.”

Another article, “Additive manufacturing 3D printers start to build factories of the future” describes some of the advances that readers of 3D Printing Industry will already be very familiar with.

Carbon’s founder and CEO gives the Economist an overview of how his company are creating the factories of the future. The article also gives further insight into Carbons plans, preferring the term digital light synthesis (DLS) Joseph DeSimone says DLS overcomes two common problems of 3D printing, speed and strength. The Economist writes this makes, “digital light synthesis competitive with injection moulding.”

Desktop Metal, Anthony Atala from the Wake Forest Institute for Regenerative Medicine, Erik Gatenholm and Hector Martinez from Cellink also contribute their perspective. The article concludes, “The 3D print shops of the future will still have some workers. But those will mainly be hardware and software engineers. And they are more likely to be wearing white coats rather than overalls.” You can read the full article here.

If you want the perspective of more 3D printing industry experts then check out our series looking at the future of 3D printing.

For more 3D printing insights and analysis, subscribe to our free newsletter and follow our active social media accounts.

Featured image shows a selection of covers from the Economist.