Desktop Metal has revealed that their long awaited metal 3D printing system uses a variety of technologies, and that 2 3D printing systems are under development.

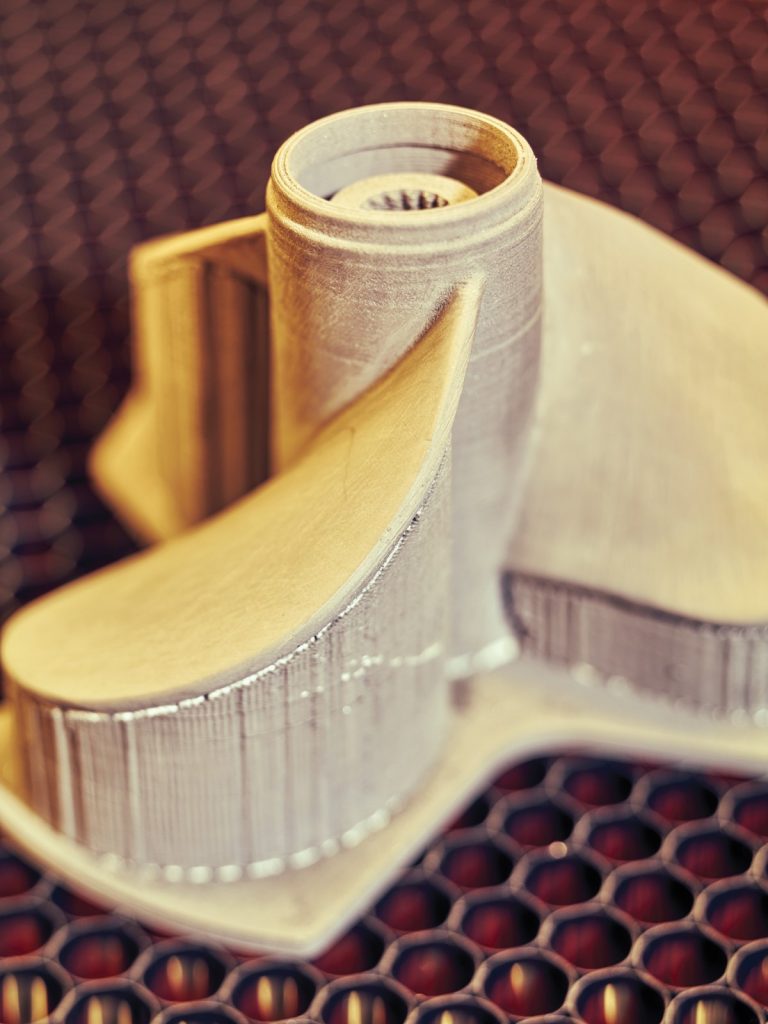

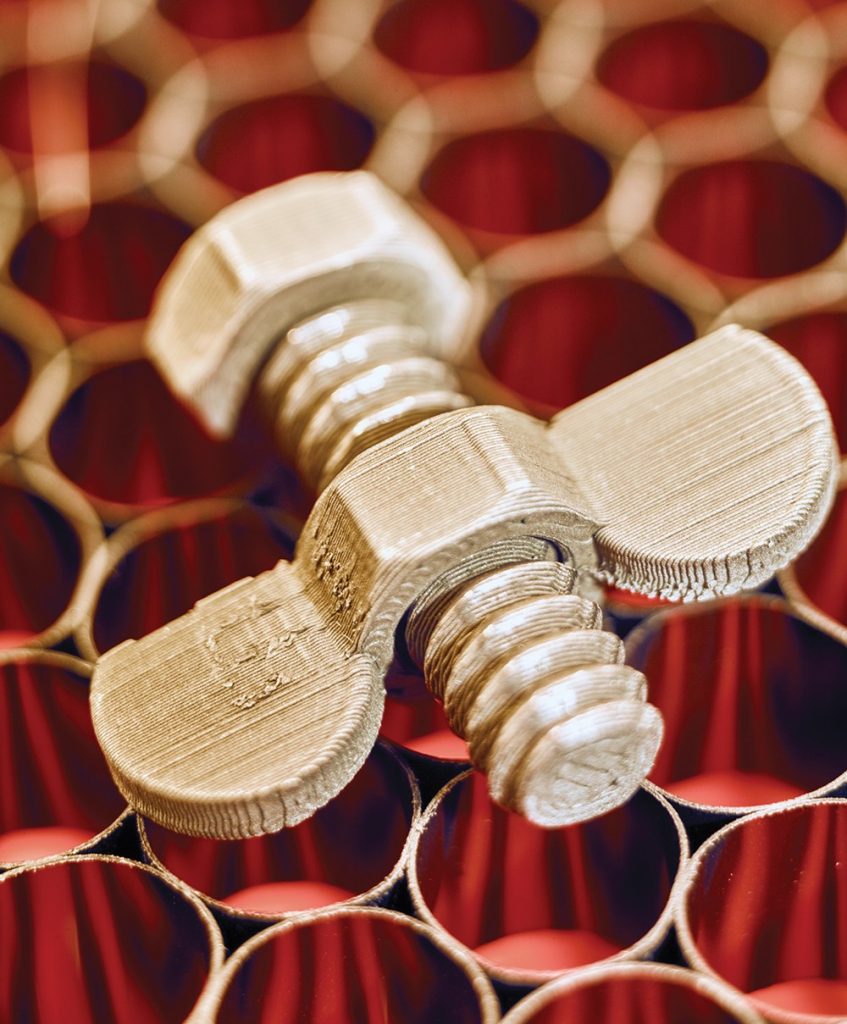

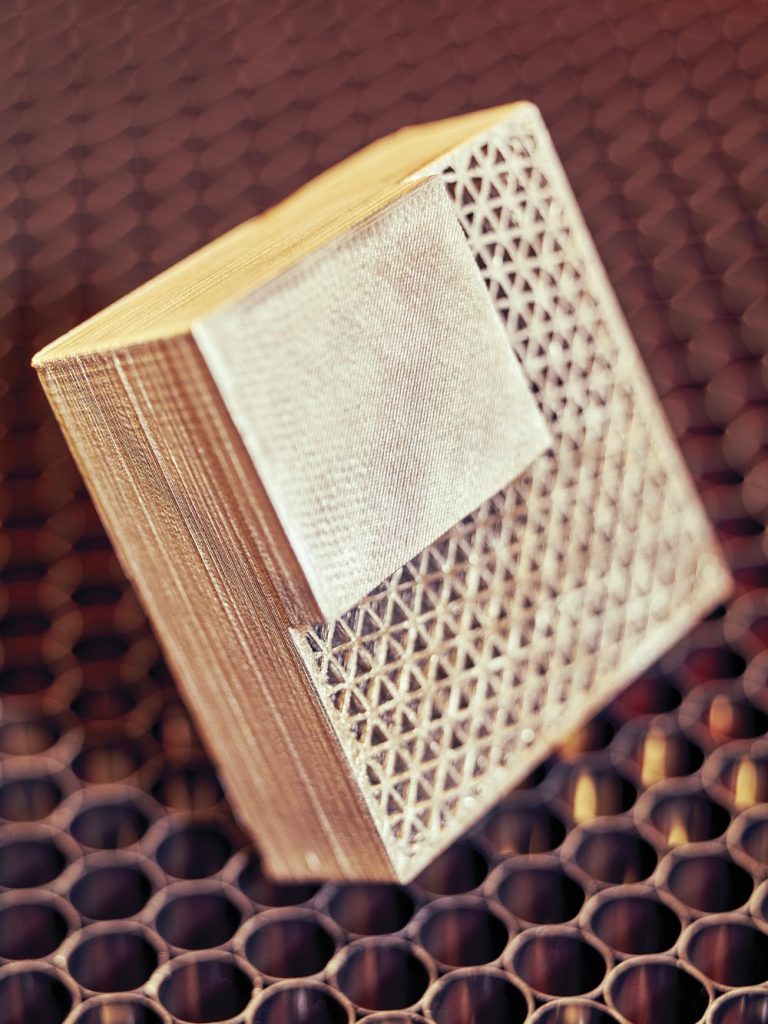

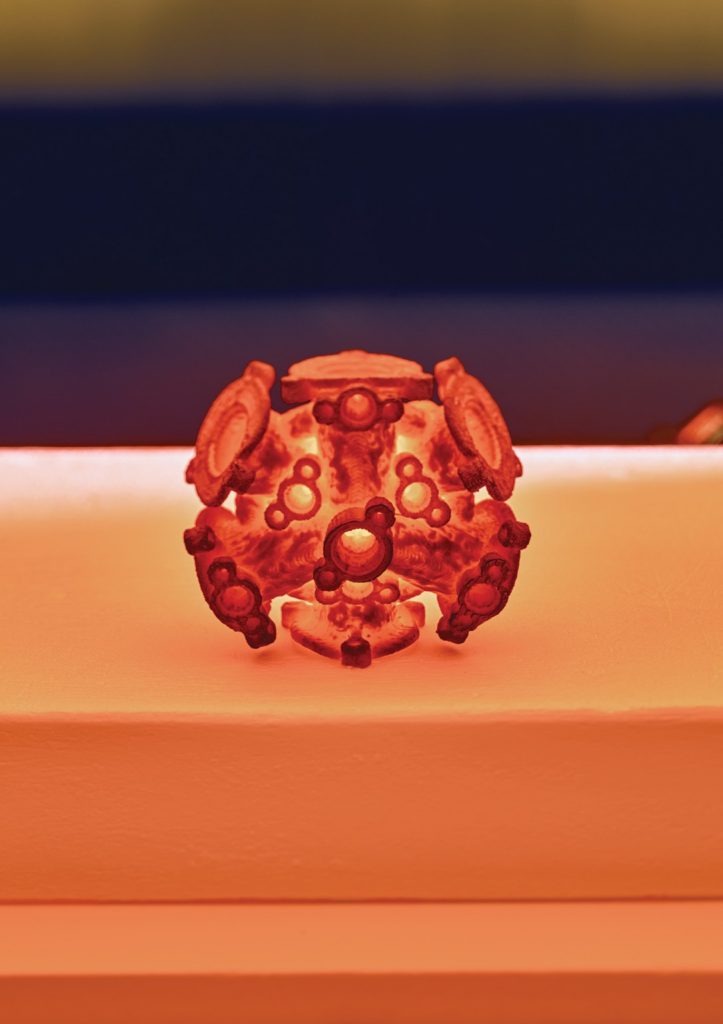

The Desktop Metal Studio system is FDM based, while the Production system is inkjet and powder based. Reservations for both Studio and Production systems are now been taken. A series of photos accompanying an article in today’s MIT Technology Review shows a selection of 3D prints from the machines.

Desktop Metal Studio 3D printer

The Desktop Metal Studio printer extrudes bound metal rods and is similar to plastic FDM 3D printers.

Technical specifications are given as 16 cm3/hour print speed, a layer height of 50 μm and a build area of 300x200x200mm (HWD).

The resulting 3D prints require post processing to debind and sinter. Desktop Metal has designed an, “office-friendly sintering furnace” for this purpose.

The SiC microwave furnace is, “Fully automated with closed loop thermal control and sized to fit through an office door.”

Scaling the process of 3D printing metal

Desktop Metal has also given initial details of a production system. The company describe this as, “the first metal 3D printing system for mass production. Arriving in 2018, the Production system delivers the speed, quality, and cost-per-part needed to compete with traditional manufacturing processes.”

Bold claims for the process are 100x faster, at a 20x lower cost. The company describes the process as Single Pass Jetting,

Breakthrough Single Pass Jetting (SPJ) process delivers speeds up to 8200 cm3/hr–100x faster than laser-based systems. With zero-tooling needed, it’s the fastest way to manufacture complex metal parts.

“Single Pass Jetting builds metal parts in a matter of minutes instead of hours,” says Desktop Metal. The forthcoming metal additive manufacturing for production is described as having a build area of 330x330x330mm (HWD), resolution is given as below 50um voxels and print speed reported as 8200 cm3 per hour.

Advantages of the Desktop Metal system are described as bi-directional Single Pass Jetting with 2 print bars containing, “over 32,000 jets” working in conjunction with powder spreaders. The 3D printing system allows, “jetting millions of droplets per second.”

Metal Injection Molding materials for 3D printing metal

Desktop Metal are working with Metal Injection Molding (MIM) powder materials. Of the 30 materials that will be available for 3D printing metal, 7 are described as core materials with the remainder listed as in development.

The core materials are Alloy Steel 4140 (Chrome Moly), C11000 Copper, Low expansion Kovar F-15, Super alloy Inconel 625, Stainless steel 316L (Austenitic) and 17-4 PH and H13 tool steel.

Development materials include Tungsten Heavy Alloy, Veloxint Tungsten Chromium, Cobalt Chrome F75, BASF Catamold and Titanium Ti64.

According to the company, working with MIM materials, “opens up an ecosystem of low-cost, high-quality alloys with a mature supply chain and well-studied process controls.”

Desktop Metal Production systems can be reserved for $5,000, Studio Systems are $1,000 to reserve. The Production System reservations require a Studio System reservation.

Pricing

Purchase of the Desktop Metal Studio System for $120,000 includes:

DM Studio Printer (add additional Printers for $49,900 + tax)

DM Studio Debinder (add additional Debinders for $9,900 + tax)

DM Studio Furnace (add additional Furnaces for $59,900 + tax)

Consumable Starter Kit (media, gas, debinder fluid, effluent filters and build plates)

Installation and training by DM Sales Partner

Cloud-based software & updates (local cloud option available)

1-year warranty and maintenance

Hardware-as-a-service (HaaS) pricing is also available. Pricing is given as $4,000/month for 36 months or $3,250 over 48 months.

The Desktop Metal Studio 3D printer is priced at $49,900.

Further details about both systems are available on the Desktop Metal website here.

To be the first with all the latest 3D Printing Industry news, subscribe to our free newsletter here. You can also follow our active social media accounts.

Desktop Metal were nominated by our readers as one of the most innovative 3D printing enterprises of the year, let us know if you agree and make your vote in the Annual 3D Printing Industry Awards here.