Today, our thought leadership series looking at the future of 3D printing takes a detour with a look at another important part of the additive manufacturing ecosystem, 3D scanning.

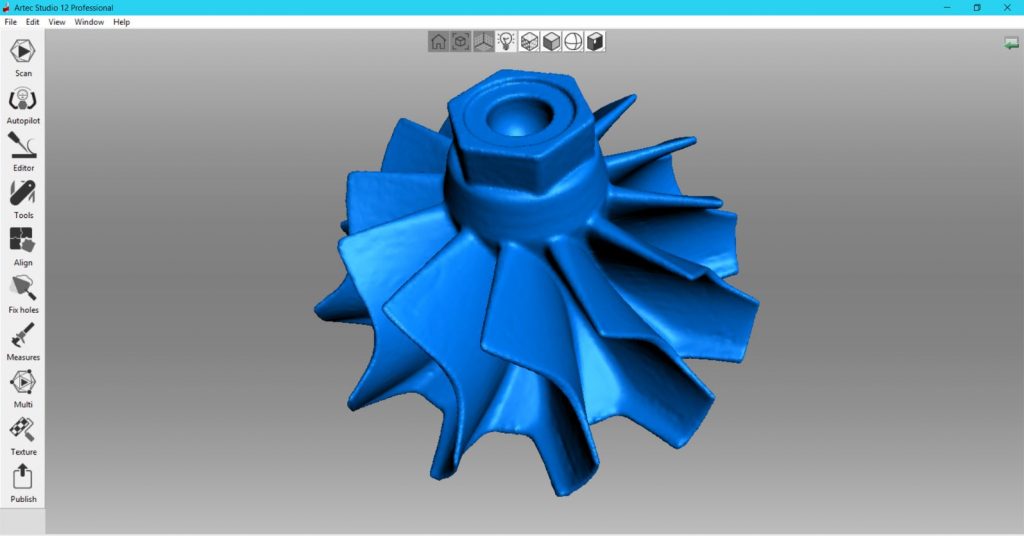

Andrei Vakulenko is Chief Business Development Officer at Artec 3D. Artec 3D provides professional solutions for 3D digitizing real-world objects with complex geometry and rich texture in high resolution.

3D Scanning: The Next Five Years

The future of 3D scanning will be based on the idea of democratizing the process. The technology has a wide range of applications, however, the learning curve for professional 3D scanning technology has limited the adoption rate. The next great race when it comes to 3D scanning is around how best to incorporate Artificial Intelligence (AI) into the technology to both add new capabilities to the technology and make the process itself as easy as taking video on a cell phone.

Artificial Intelligence

AI is starting to and will continue to shape how professional 3D scanners are designed – the recent release of the NVIDIA Jetson mini supercomputer is a significant advancement to enable this shift. Although the industry is not here yet, 3D scanners will soon be able to learn to understand what they are scanning. This will increase the customer base enormously, as 3D scanning will be used not only to create replicas of physical objects, but also to perform quality control tasks during the scanning itself. The interesting applications will be where it is not easy to give a “yes” or “no” answer, but rather requires some form of judgement.

For instance, if a 3D scanner can understand that it is scanning the exterior of an airplane, it will not only be able to register dents on the plane’s surface, but be able to take it a step further and flag which ones require immediate attention and which ones are insignificant enough to leave for the time being. This creates a more integrated process and turns a 3D scanner into more of a total solution for certain industries and processes.

Another scenario in the same vein would be the quality control of car seats and making sure the seams are straight enough to be sold to the public. At the moment, these types of decisions are made by a person, who just judges by eye which seams are straight enough and which are unacceptable. There is an intuitive margin of error that that person uses to determine if the quality is acceptable. In the future, an AI-based 3D scanner will be able to make these “subjective” decisions themselves.

This concept would also be easily applied to the medical field for examining the shape of the body and the curvature of a person’s spine. With these advancements, a school nurse could use a 3D scanner to check the spines of all of her students, and if any issues were found, she could organize for that child to be sent to a specialist for further diagnosis and treatment.

With these future AI capabilities, new reverse engineering, quality control, and medical applications create new markets for 3D scanning. The medical industry is particularly interesting as it is quickly embracing the concept of customized medicine. While this generally applies to drug treatments tailored to a specific person’s needs, it will expand to encompass the customization of medical devices to a patient’s body, which will require 3D scanning.

Deep Learning

While the AI applications above reflected and mimicked human intelligence – visual perception and decision-making, there are also opportunities to meld deep learning with 3D scanning technology. 3D body scanning serves as a good example for this.

Artec 3D is currently working in conjunction with the University of Luxembourg on a deep learning project. An Artec Shapify Booth, a 3D full body scanner, is set up in a public area of the university for 3D scanning volunteers. The body scanning data collected is being analyzed by scientists at the university’s Interdisciplinary Centre for Security, Reliability and Trust (SnT) to better understand the human posture and how to fit a parametric model to 3D scans. Body scans garnered via the Shapify Booth are high precision, however, unless a person is scanned in skin-tight clothing, it won’t show the true measurements of a person’s body. The goal is to understand how to automatically fit a parametric model to the 3D scan so that a fully clothed person can be scanned and accurate body measurements can be generated.

Perfecting this technology would result in the ability to use the 3D scan to automatically create a 3D model that can move anatomically. This could be used for a virtual dressing room, animating a person for television or film, or even inserting someone into a video game or virtual environment so that they have an accurate avatar. These are just a few ways in which this research could be leveraged.

Industry Limitations to Overcome

While there are some very intriguing applications on the horizon, there are still some hurdles that 3D scanning will have to overcome. When cheap 3D sensors first appeared – like PrimeSense and Intel RealSense – there was a lot of excitement and developers rushed to create innovative apps that would work with these technologies. However, the quality of the scanning was extremely poor. This excitement and the resulting unattainable expectations was a misstep for the industry that impacted consumer perception of the technology. However, as time has passed, professional 3D scanners have become cheaper and cheaper. As the price point comes down, this should once again spur interest into developing apps to work with 3D scan data and 3D models that will boost the technology’s popularity.

Another traditional hurdle within the 3D scanning field has been lighting and the challenge of scanning outdoors and in uncontrolled environments. There have been some recent advancements to overcome this obstacle, but the majority of the industry’s technology still struggles with this issue. The new Artec Leo can scan in sunlight with high accuracy, so now 3D scanning can be conducted in areas that were previously impossible to scan in or very difficult – requiring a tent to be pitched or other methods to create shade and control lighting. These advancements will be especially useful for forensics, archeological digs, or any quality control that needs to be performed outside.

While 3D scanning is already widely used in numerous, diverse applications, the advancements of AI and deep learning will make the technology even more intuitive and feature-rich. While 3D scanning still somewhat lives in the shadow of 3D printing, this will soon be proven an old way of thinking.

More information about Artec 3D is available here.

This is an article from the 3D Printing Industry thought leadership series looking at the future of 3D printing.

If you’d like to give your perspective on the future of additive manufacturing or trends in the 3D printing industry, then get in touch.

For further insights into the future of 3D printing, sign up to our newsletter and follow our active social media channels. Let us know your thoughts about this perspective on the future of 3D printing in the comments below.