I spoke to the manager of DARPA’s 3D printing program about how the Pentagon’s technology incubator is using additive manufacturing.

This week in Las Vegas the Defense Advanced Research Projects Agency (DARPA) will host, “the world’s first, all-machine hacking tournament.” The winner will then face the “World’s best human hackers in the annual DEF CON Capture the Flag competition.” I asked DARPA’s Mick Maher whether the agency is planning something similar for 3D printing, for now nothing is on the cards he says. Makers with a penchant for watching machines battle can always enjoy the recent reboot of Robot Wars.

Mick Maher joined DARPA in 2011, prior to this he studied chemistry and was initially hired by the Martin Marietta Corporation to run a chemistry lab in Baltimore. “They had a big problem on the production floor. On my first day they said you’re no longer in the chem lab, you’re now on production.”

Chemistry’s loss was 3D printing’s gain and after stints at DuPont, AAI and the Army Research Lab (ARL) his work on composite manufacturing caught the attention of DARPA. “DARPA were paying attention to what I doing with materials and manufacturing and when the opportunity came to run the Open Manufacturing program it became a good fit for both me and DARPA. And the rest in history,” he says.

DARPAs Open Manufacturing program began in 2012. Maher explains, “The inspiration around the program was that it was getting really hard to get new manufacturing technology into use.” In particular while metal additive manufacturing was showing signs of promise the technology was not making its way into production in any concerted manner. “The reason was that they didn’t trust the manufacturing process,” says Maher. Potential users were unsure about how 3D printing, “processes scale-up and how the manufacturing parameters that we work with effect the [material] properties.” And so the Open Manufacturing program was created.

3D Printing at the frontier of technology

Of course this was not DARPAs first venture with 3D printing. While the world was occupied with Pokémon for the first time, Gameboy rather than iPhone, and Keanu Reeves was using his knowledge of Kung Fu to defeat Agent Smith, DARPA were already working with the technology. In the, “Early 2000’s maybe late 90s DARPA had done some work looking at 3D additive for ceramics, but as tools for casting,” says Maher. “So if you wanted to put flow paths in turbine blades, that was something we did a long time ago.” Its probably worth bearing this in mind the next time you read about the latest 3D printing “world first.”

In the present day, rapid qualification is, “where we think we’re going to have a really big impact with the program,” says Maher. The qualification and validation of materials and processes is an important dimension for integrating 3D printing into production. Removing this barrier is a recurrence theme in conversations with people working at the frontiers of additive manufacturing.

DARPA’s Open Manufacturing program has three strands. The first is not directly related to 3D printing but looks at bonded composites, “We’ve come up with a methodology that determines what a good quality output of bond is, a composite bond, and developed a bunch of processes that go along with that to improve the reliability of that process including things like plasma surface treatment, new inspection techniques that can verify the cleanliness of a surface before you bond.” Lockheed Martin, Boeing and Northrup Grumman make use of these techniques for bonded aircraft structures.

Making 3D printing stronger and cheaper

3D printing is the focus of the two remaining strands, the Rapid Low Cost Additive Manufacturing (RLCAM) effort and the Titanium Fabrication (tiFAB) effort.

“The [RLCAM effort] is with Honeywell and they’re working on Direct Metal Laser Sintering (DMLS). In particular the material they’re using is Inconel 718 plus,” says Maher. Inconel 718 is a nickel-base super alloy; the metal performs well in extreme environments where high temperatures are present and is resistant to corrosion. These characteristics make it a strong candidate for use in aircraft engines. Maher explains, “We have got a framework together using physics based models. A network of physics based models that model everything from the powder bed to the melt pool, to the laser. We’ve run a series of experiments to calibrate those models so that we understand how these parameters effect the properties and microstructures that are developed within the metal and include some of the environment conditions or starting conditions like the powder size or powder chemistries.” In particular the agency works closely with Lawrence Livermore National Labs.

“We’ve developed terabytes of information with very small builds. What we’ve been able to do with, in particular, Honeywell is be able to basically abstract some of the data we’ve developed and pull that into mathematical models, physics based models and set conditions by which we can basically visualize that parameters will give us a good part and where the parts will begin to incur defects like boiling and porosity, things like that,” says Maher. These areas are discussed in more depth here. But basically if the surface of the melt pool exceeds boiling point vapor recoil momentum will occur. This expands the pool further and can cause weakness due to porosity in the final 3D printed component.

This means DARPA now have a very clear idea about the optimal laser scan strategy for 3D printing metal and the interaction of conditions, or metrology, in the build chamber. “We do a lot of our own in situ inspection, with pyrometers [infrared thermometers] and high speed optical imaging,” says Maher. “We’re looking to go into phase III with Honeywell and we’re looking to demonstrate on actual flight hardware that you can reduce the amount of testing,” he says. This reduction in testing might, “almost cut it in half, and be able to have the same reliability or prediction or performance,” he adds.

Digital Alloys

The project may also have application in creating meta-materials or digital alloys in the future. This futuristic group of materials might use 3D printing techniques to control the microstructure and result in production of a component that has varying properties, such as magnetism. “We took those traditional metallurgical models and tied the performance drivers back to manufacturing parameters. What this enables is once you’ve got that model developed and refined and calibrated you can now start generating the distribution of material properties virtually,” says Maher.

“The big thing with the Open Manufacturing program is we use a combination of a network of models and experimental data and understanding the uncertainly of each,” Maher explains.

The second program uses Electron Beam Additive Manufacturing (EBAM), DARPA are working with a wire-based technique rather than the powder bed method used by Arcam. 3D printing metal using wire fed methods enables much larger components to be produced and the process used in the tiFAB project is similar to the Rapid Plasma Deposition (RPD). RPD was developed by Norsk Titanium, who recently announced a $1 billion project in Plattsburgh, New York.

Maher explains how DARPA’s tiFAB effort works, “That’s with Boeing and we’re working with Titanium 6AL-4V (Ti-6Al-4V).” The 3D printing process is handled by Sciaky of Chicago who acts as a sub-contractor for Boeing. “When you look at DMLS you’re probably laying down about a quarter pound per hour, the Sciaky [EBAM] machine is laying down about 20 lbs. per hour,” says Maher.

For tiFAB and Boeing this process has some interesting applications for making various structures. Maher says, “It could be wings, it could be fuselage components. Think about any of the kind of structures where you have to machine away a lot of material to get that the configuration that you want.” Traditional subtractive processes, where machining is used to remove material, result is a substantial amount of waste. The material that ends up on the factory floor compared to the material in the final product can be measured using the buy-to-fly ratio.

“Where-ever you see a component that is going to have a high buy-to-fly ratio, our thought process is you come in with the process that tiFAB is working with and get near net shape and basically be able to trade off that machining cost. It ends up being a much better cost case,” explains Maher.

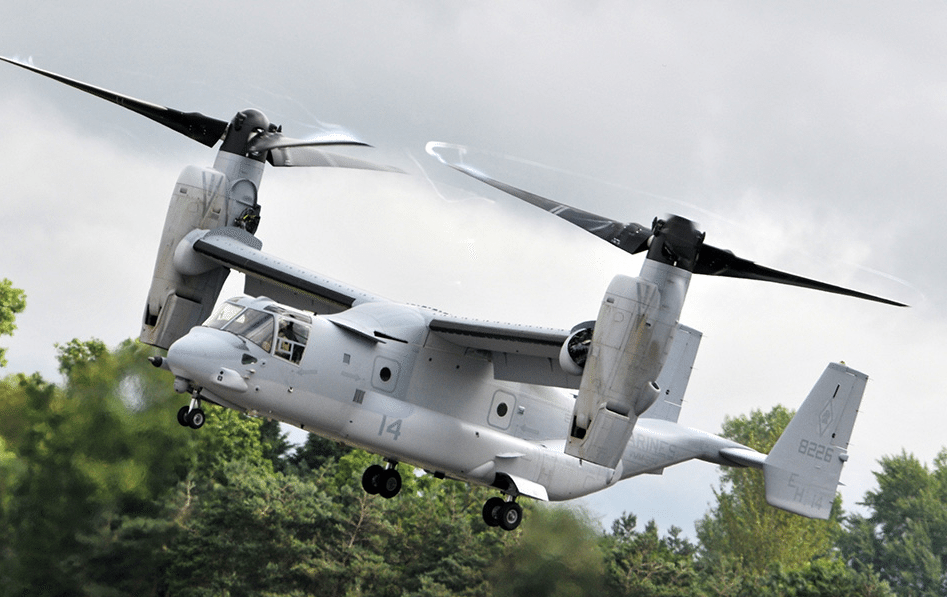

It was recently reported that one Boeing’s MV-22B Osprey tiltrotors, “Made its first flight incorporating a flight-critical component built using 3D-printing techniques.” According to Boeing, “The V-22 Osprey is a joint service multirole combat aircraft utilizing tiltrotor technology to combine the vertical performance of a helicopter with the speed and range of a fixed-wing aircraft. With its rotors in vertical position, it can take off, land and hover like a helicopter. Once airborne, it can convert to a turboprop airplane capable of high-speed, high-altitude flight. This combination results in global reach capabilities that allow the V-22 to fill an operational niche unlike any other aircraft.”

Partnership with Universities

Another component of the Open Manufacturing project is underway at Penn State University. “It’s our Manufacturing Demonstration Facility (MDF),” says Maher. The MDF is, “A training point for helping to distribute what we do in the Open Manufacturing program and making the community aware of it. And then they actually do some demonstration of technologies like this subtractive/additive technique for us,” says Maher. The MDF at Penn State University is also important to DARPA in another way. “It’s my honest broker to where these models should be used and how do they compare to some of the existing models we have,” he says.

Lehigh University, sometimes referred to as a hidden Ivy League university, and Iowa State are also on the Boeing program. “Honeywell tends to work with Penn State directly,” adds Maher.

“The thing with the tiFAB program is, when we get that framework out and its verified and validated, which is an important part of Open Manufacturing, the ability to be used by programs where they are making one or two vehicles you can realize the true capability of additive manufacturing because you don’t have to test your way through that qualification/certification process,” says Maher. Some of this work involves presenting the results of DARPA’s projects to wider industry groups. A recent example of this was the presentation given to America Makes. Maher says, “We presented all our data and the outcome of the framework and models, we did a good outreach to the community.”

Depending on how deep down the rabbit hole you’ve fallen, DARPA’s work can be fascinating or frightening. The agency is synonymous with paving the way to the Internet and more recently creating the onion router (Tor) technique for anonymous online communication. Detractors point to initiatives like the Social Media in Strategic Communications program for, “detecting and conducting propaganda campaigns on social media” or the nightmare inducing Big Dog. But with Facebook getting in on psychological manipulation, Google buying Boston Dynamics and Apple focused on preserving enjoyment of Dragons for an elite majority, there is something refreshingly honest about DARPA’s mission to, “create technological surprise for U.S. enemies.” Especially, while big tech companies claim to be making the world a better place.