Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

Belgian 3D printing company Materialise and Renishaw have announced a strategic partnership to bolster efficiency and productivity for manufacturers utilizing Renishaw’s AM systems.

The collaboration equips Renishaw’s AM system users with Materialise’s specialized build processor software for the RenAM 500 series, alongside access to Magics, Materialise’s premier data and build preparation software. This integration aims to streamline workflows, improve control over the 3D printing process, reduce production time, and improve overall AM efficiency.

“Working with Materialise enables us to support Renishaw users deploying 3D printing in a host of different manufacturing applications,” said Matt Parkes, AM Strategic Development Manager at Renishaw. “Their next-generation build processors, in combination with their software portfolio, complement our recent technology updates. We’re pleased to be collaborating on the tools needed to support the industry as metal 3D printing becomes an essential piece of the manufacturing puzzle.”

Streamlining metal AM workflows

Materialise notes that laser powder bed fusion (LPBF) is pivotal in the growth of metal AM for large parts, offering customizable settings for increased production. However, mastering this technology can be daunting for novices, prompting the need for software solutions to streamline the process and address workflow complexities.

Materialise’s new build processor software enhances Renishaw’s TEMPUS technology for the RenAM 500 series, enabling simultaneous laser and recoater operation, saving time while maintaining part quality. By efficiently handling complex geometries and high part volumes, it also allows custom print parameters at the part level, improving productivity and facilitating mass production of identical or diverse parts.

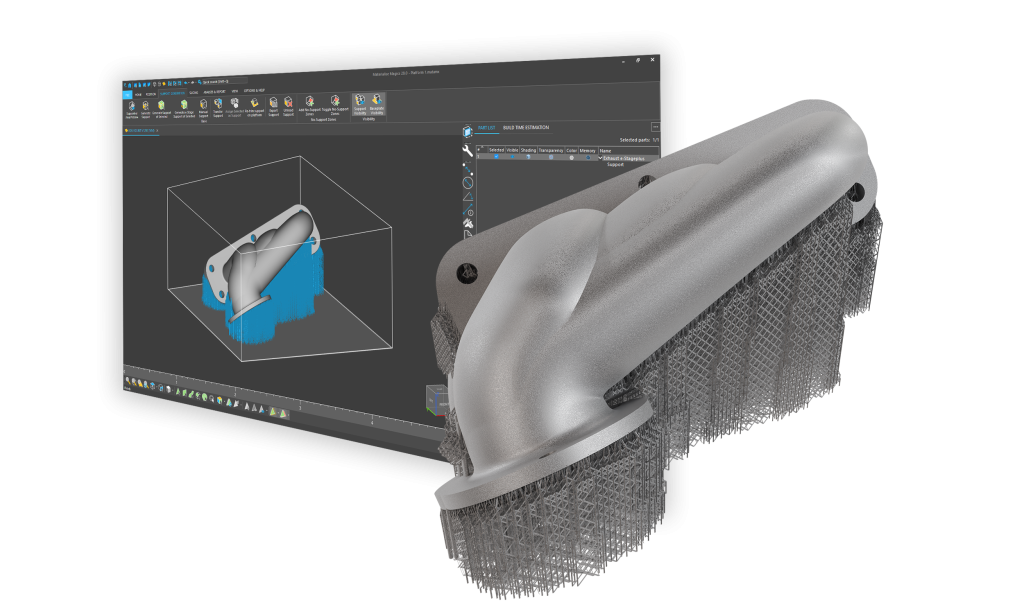

Materialise’s build processor software seamlessly integrates with Renishaw’s AM systems, enabling easy connection to Magics, a technology-neutral software for data and build preparation. Magics offers advanced workflow control and automation, including e-Stage for Metal+, which uses physics-based modeling to streamline data and build preparation for LPBF systems, automating support structure generation.

Manufacturers can use Materialise’s Build Processor Software Development Kit to create custom processors for their metal 3D printing requirements, enhancing cost efficiency, production speed, and part quality. This enables the production of intricate parts and mass customization with consistent quality, shorter lead times, and lower scrap rates.

A collaborative approach toward metal AM

As companies look to adopt metal AM technology for large-scale production, partnerships are becoming increasingly crucial. For instance, Xact Metal partnered with System Create Co. to broaden access to cost-effective metal 3D printing for SMEs in Japan. With three decades of 3D printing experience, System Create Co. will provide technical support for Xact Metal printers, furthering its mission of enabling widespread adoption of affordable metal 3D printing technology in Japan.

In a joint effort, Oerlikon‘s subsidiary Oerlikon AM and US-based 3D printer manufacturer 3D Systems collaborated to advance the scalability of metal AM. Leveraging 3D Systems’ Direct Metal 3D printing technology and Oerlikon AM’s proficiency in surface engineering, the collaboration aims to expedite market penetration, particularly in the semiconductor and aerospace sectors. Additionally, Oerlikon AM has bolstered its capabilities by acquiring its fourth 3D Systems DMP Factory 500 printer, facilitating innovation and precision in metal additive manufacturing tailored for demanding industries.

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows key visual for e-Stage for Metal+. Image via Materialise.