LINK3D, a New York-based 3D printing workflow software provider, has partnered with the German AM R&D hub Aachen Center for Additive Manufacturing (ACAM) to promote AM industry in Germany and Europe.

LINK3D will build a showroom to demonstrate the capabilities of its AMES & Additive Workflow Software to ACAM partners such as the Fraunhofer Society, a conglomeration of 69 research institutes across Germany.

On the partnership, CEO of LINK3D, Shane Fox, said, “it’s an honor to be collaborating with an organization like ACAM and Fraunhofer as they have an extensive knowledge and experience around additive manufacturing. We believe this collaboration will introduce new technologies that the industry has never seen.”

Streamlined 3D printing

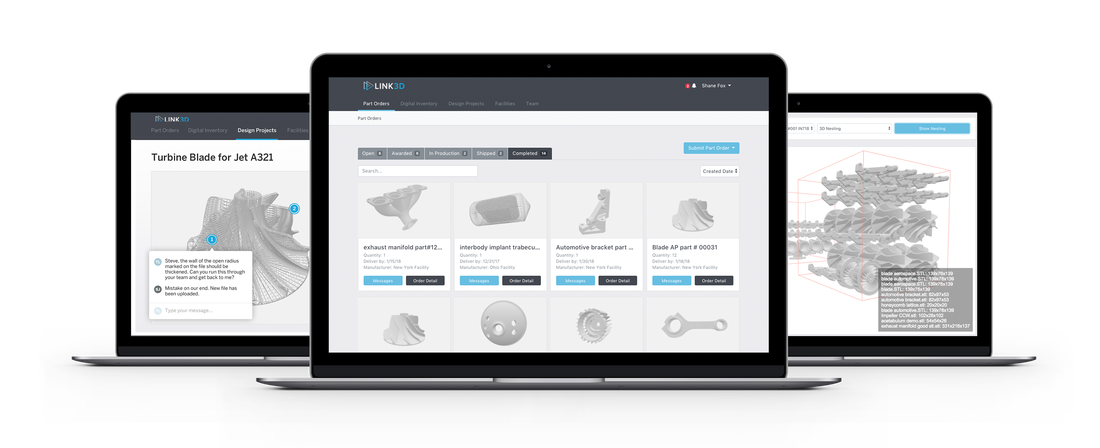

A live demonstration will be held for LINK3D’s automation workflow system. The invitees will be able to familiarise themselves with the software and see how it handles: order submission processes, quoting and cost tracking, production scheduling, customer feedback, and data analytics.

A training center is also planned as part of the project, where employees of the training partners can learn how to optimize manufacturing operations with LINK3D.

Since the founding of its Digital Factory in 2017, LINK3D has become one of the leaders in the workflow management software for AM. Most recently, the company added Production Planning System (PPS) to optimize its Digital Factory.

“Aachen is the cradle of laser-based metal AM technologies – we won’t forget this heritage – but a large part of the AM future will be decided in the digital world.”

Managing Partner of ACAM, Johannes Schleifenbaum said further, “we will support this with the formation of a ‘digital additive enterprise’, where customers can holistically experience the disruptive power of AM. We are very glad that LINK3D will be at our side on this journey!”

On-demand 3D printing

In recent times, many AM companies have realized the importance of real-time and cloud-based technologies.

This year, Xometry raised $25 million in funding and acquired MakeTime. The company also added HOOPS communicator to its instant quoting engine.

Earlier this month, the nano-scale 3D printing service provider, BMF Material Technology (Guangdong, China) partnered with cloud-based software Onshape, to provide its customer with real-time CAD support.

In a similar venture, 3YOURMIND, an AM workflow company, and 3D Center announced the launch of an online 3D printing platform.

Catch all the 3D printing related news by subscribing to our 3D printing newsletter. Also, join us on Facebook and Twitter.

For jobs in the industry, please visit our 3D printing job site.

Featured image shows data analytics generated through LINK3D’s PPS. Image via LINK3D