HRE Wheels, a California-based wheel manufacturer, has added a new titanium 3D printed wheel to its HRE3D series. The second generation wheel, installed on a 2019 Ford GT, was designed and 3D printed with the help of metal 3D printing specialist GE Additive.

HRE President and CEO Alan Peltier, said, “We’re proud to be breaking new ground in wheel manufacturing with the updated HRE3D+ wheels.”

“Working with GE Additive have given us access to some truly cutting-edge technology, and we’re exploring the future of wheel technology together with tools that will continue to evolve over the next few years.”

From forging to 3D printing

HRE manufactures custom forged one-piece and three-piece wheels for sports and luxury vehicles. A one-piece wheel, also called a monoblock, is either forged or cast from a single piece of metal, whereas a three-piece wheel is separated into a center, inner and outer barrel, all of which can be made using different materials and processes.

HRE’s wheels are usually made with CNC machines. However, in this method about 80% of the material is removed and wasted from a 100-pound aluminum block. CNC machining the wheels also somewhat limits the design creativity.

Through its partnership with GE Additive, HRE Wheels has been exploring alternative methods of wheel manufacturing.

Reinventing the wheel

In 2018, HRE Wheels partnered with GE Additive’s consultation service AddWorks to 3D print a wheel using the Arcam Q10 and Q20 electron beam melting (EBM) systems. This year, HRE Wheels and GE Additive put their heads together to improve on the previous design of the HRE3D wheel.

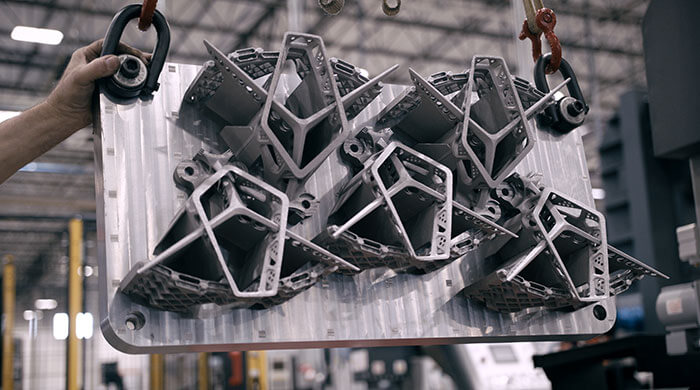

The second generation wheel is 3D printed in titanium in two different sizes for the rear and front of the car. The wheel parts were made using an EBM 3D printer by Arcam AB and the Concept Laser X LINE 2000R. Before installation, the 3D printed parts were tested using GeonX Virfac software which evaluates finished components for design intent.

One big different between the first model and this second generation wheel is the weight. Each rear wheel, with twenty-one inches diameter, weighs 19lbs, and the front wheels, with a twenty-inch diameter, weigh only 16lbs. On average HRE is saving four pounds per wheel compared to the previous model.

With plans to continue this partnership further into the future, Peltier concluded, “We can’t wait to see what we’re able to accomplish next.”

For more news on how additive manufacturing is changing the world, subscribe to our 3D printing newsletter and join us on Facebook and Twitter. Looking for a job? Visit our 3D Printing Jobs board.

Featured image shows a purple Ford GT 2019 fitted with HRE3D wheels. Image via HRE Wheels.