Essentium, Inc., the developer of the High Speed Extrusion (HSE) FDM 3D printing platform, has exhibited its 180-S platform in action for the first time at at Rapid + TCT 2019.

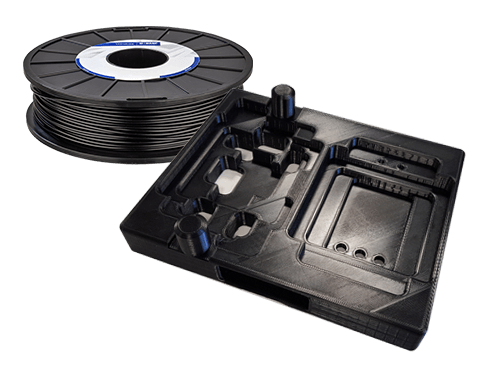

The company also demonstrated its electrostatic discharge (ESD) safe Ultrafuse Z PCTG, 3D printing material, which protects electrostatic-sensitive devices.

Faster 3D printing with HSE

Headquartered in College Station, east Texas, Essentium specializes in the development and provision of additive manufacturing materials and processes. This includes HSE and FlashFuse technology, which it has combined in its 180-S platform, an additive manufacturing system that intends to address both the speed and strength issues with traditional FDM/FFF 3D printers.

Essentium claims that its 180-S 3D Printer is 10x faster, printing faster than 500mm a second, and 5x more accurate than these traditional 3D printers. This performance is achieved by utilizing a non-slip, high torque extruder system and all linear motor. When printing, the HSE nozzle can adjust to temperatures from 20-600 degrees.

Blake Teipel, CEO and Co-founder of Essentium commented on the advantages of HSE, “While companies have already begun to include 3D printing in their production processes the bulk of manufacturing continues to be done by traditional CNC machines as firms are hindered by speed and scale obstacles.”

Adding, “The Essentium HSE is smashing through these barriers, providing speed without compromising the performance of the printed part to accelerate the shift to large-scale additive manufacturing. It is enabling wide-ranging applications as firms enter Industry 4.0 helping to drive greater innovation, efficiency and sustainability across their product development lifecycles.”

The company claims that one unnamed customer is using the technology, which “decreased its time to tool by 85 percent over aluminium tooling and achieved a 97 percent cost savings over other traditional methods.”

3D printing with Ultrafuse

With regard to materials, the company primarily produces filaments for general use in polymer processing and is also known for its FlashFuse technology – a method combining 3D printing with electric welding. To supplement its printer, Essentium have also developed a ESD safe material in tandem with BASF.

Called Ultrafuse Z PCTG it is an amorphous copolyester developed specifically for electronic applications. The filament can be processed at speed while being strong enough to withstand impact loading, fatigue, or cyclic loading and protect electrostatic-sensitive devices.

It has a tensile strength of 46 MPa, making its strong enough for lightly loaded fixtures. It demonstrates 35% elongation at break, and a notched impact strength of 74 J/m – significantly higher than comparable PETG.

The material is specially suited to the fabrication of “handheld tools, general assembly fixtures for electronics, robotics and automation components,” and “parts for explosion proof environments.”

As demand for industrial scale 3D printing continues to grow, Essentium has been keen to partner with digital manufactures around the world, most notably Belgian software and 3D printing service provider Materialise.

While there has existed a partnership between the the two companies since November 2018, it received an update at this year’s RAPID + TCT 2019, where it was announced that Materialise’s Magics Essentials software will be integrated with the HSE 3D Printing Platform.

Prior to this, Essentium announced a $22.2M Series A funding from BASF and Materialise in January this year, which aimed to develop HSE materials and introduce an open market model for 3D printing. Essentium have also recently moved its headquarters to a larger facility in Austin, Texas to sustain its growth.

Don’t forget to vote for the 2019 3D Printing Industry Awards.

Subscribe to our 3D Printing Industry newsletter and follow us Facebook and Twitter for the latest news in additive manufacturing.

Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

Featured image shows Essentium’s High Speed Extrusion 3D Printing Platform. Photo via Essentium.