Inkbit, a startup of the Massachusetts Institute of Technology (MIT) Computer Science and Artificial Intelligence Laboratory (CSAIL) has developed an industrial 3D printer with machine-vision and machine-learning technologies.

“The company was born out of the idea of endowing a 3D printer with eyes and brains,” said Davide Marini, co-founder and CEO of Inkbit.

“Everyone knows the advantages of 3D printing are enormous, but most people are experiencing problems adopting it. The technology just isn’t there yet. Our machine is the first one that can learn the properties of a material and predict its behavior.”

“I believe it will be transformative because it will enable anyone to go from an idea to a usable product extremely quickly. It opens up business opportunities for everyone.”

Multi-material inkjet 3D printing

In 2015, Inkbit co-founders Marini, Wojciech Matusik, an associate professor of electrical engineering and computer science, Javier Ramos, Wenshou Wang, and Kiril Vidimče sought to develop a high speed, high precision 3D printer capable of processing high-quality materials.

According to the team, rubber-like materials such as silicone, and high-temperature materials such as epoxy, are among the most difficult to 3D print and lead to uneven distribution and print process failures like clogging. Such materials are also prone to shrink over time.

To address this, a 3D printer with the ability to produce 10 materials at once with machine vision was constructed. This would lead to the commercialization and development of Inkbit’s multi-material inkjet 3D printer dubbed as “Snapper”.

The “eyes and brain” of a 3D printer

Matusik’s research group integrated a custom optical coherence tomography (OCT) scanner, which uses light with a long wavelength to see through the surface of materials as well as scan layers at a resolution the fraction of the width of a human hair. This acts as the “eyes” of the 3D printer enabling autonomous corrections in real-time, i.e., compensation for warping and shrinkage with a machine-learning system or “the brain”.

Presently, the Snapper 3D printer has 16 print heads to create multi-material parts and a print block big enough to produce hundreds of thousands of fist-sized products a year. This allows users to prototype and additively manufacture new objects on the same platform. The system can also accurately 3D print flexible materials around objects with computer chips or electronic components.

“Before, people could make prototypes with multi-material printers, but they couldn’t really manufacture final parts,” added Matusik. “This is something that’s not possible using any other manufacturing methods.”

Commercializing the Snapper

The first industrial Snapper 3D printers, which features a build volume of 450 x 250 x 250mm, will be acquired by Johnson and Johnson, a strategic partner of Inkbit. Following this, the systems will be shipping later this year.

Moreover, a proprietary system for mixing two materials just before 3D printing will be integrated into the Snapper systems to be shipped next year.

“Some of this is so far ahead of its time,” Matusik says. “I think it will be really fascinating to see how people are going to use it for final products.”

Find the latest additive manufacturing news by subscribing to our 3D Printing Industry newsletter and following us Facebook and Twitter.

Also, visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

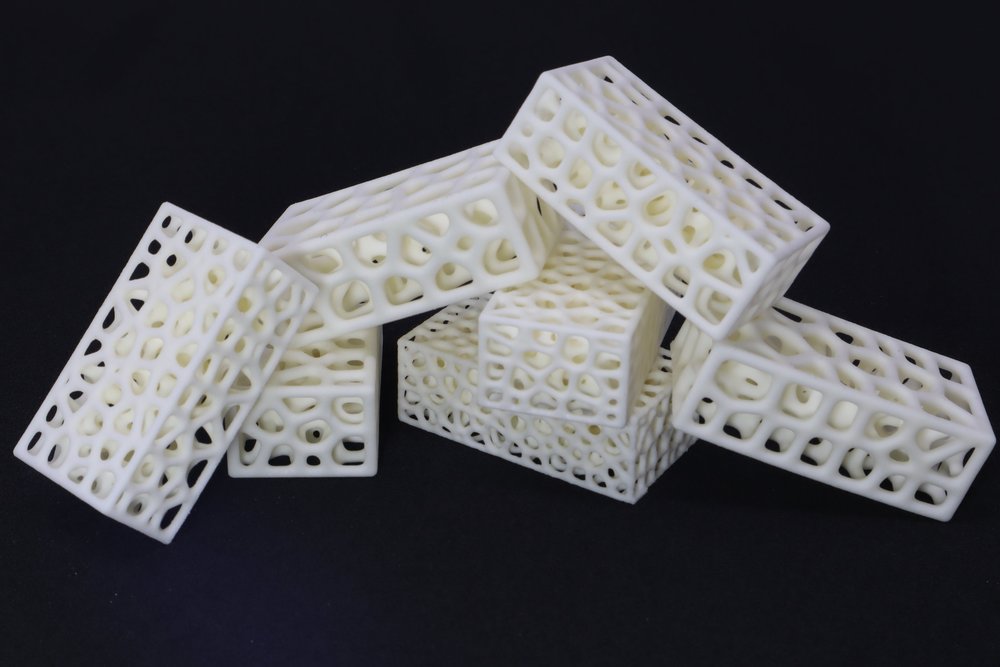

Featured image shows a flexible lattice structure produced by Inkbit’s Snapper 3D printer. Clip via Inkbit.