Innofil3D, a Dutch 3D materials manufacturer acquired by BASF in 2017, has launched two new filaments for FFF 3D printers. One of these materials, Ultrafuse Z PCTG, is the first electrostatic discharge (ESD) safe filament made by chemical giant BASF. The second, Ultrafuse TPU 80A LF, is a tough and flexible material made for both bowden and direct drive extruders.

Both materials contribute to BASF’s growing “Ultra” series of 3D printer materials which includes Ultrasint, for PBF systems, and Ultracur3D for SLA. Ultrafuse is a brand of reinforced filaments developed to have properties suitable for functional prototyping and small series production of parts.

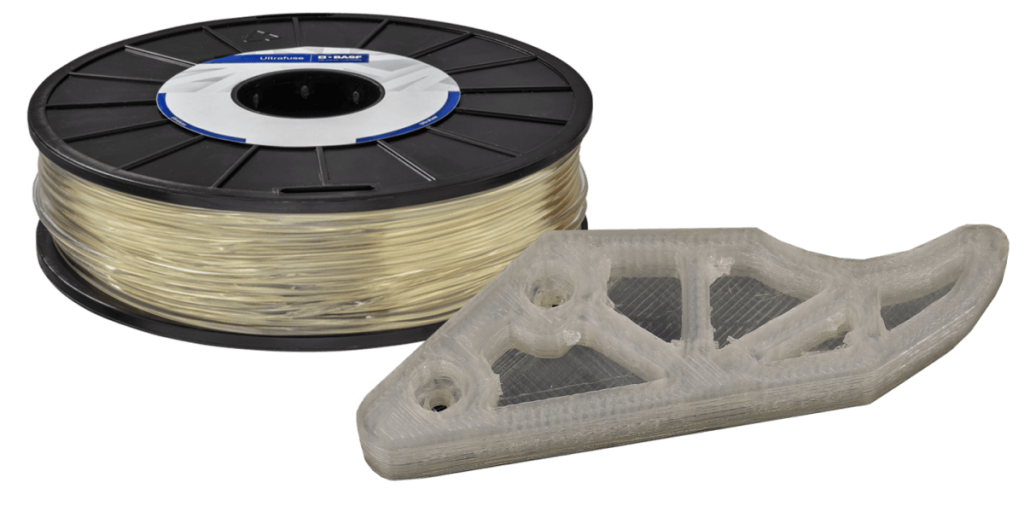

The Ultrafuse filament range from BASF and Innofil3D covers PA, TPU and PCTG polymers. Working with High Speed Extrusion (HSE) technology developer Essentium, BASF has also developed Ultrafuse 316LX, a metal-plastic composite filament that can be 3D printed on a desktop machine and sintered afterwards to make a metal part. In this latest release, BASF and Essentium have worked together again to produce the ESD safe Ultrafuse Z PCTG.

3D printing parts for explosion-prone environments

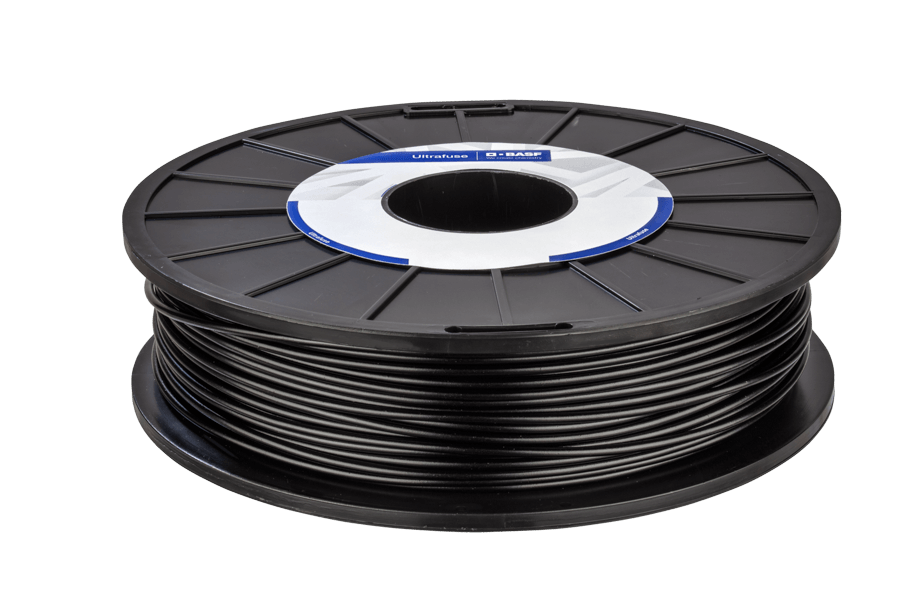

Ultrafuse Z PCTG is an amorphous copolyester developed specifically for electronic applications. In the official description provided by BASF, the material is specially suited to the fabrication of “handheld tools, general assembly fixtures for electronics, robotics and automation components,” and “parts for explosion proof environments.” It has a tensile strength (when 3D printed flat with infill lines parallel to testing direction) of 46 MPa, making its strong enough for lightly loaded fixtures. It demonstrates 35% elongation at break, and a notched impact strength of 74 J/m – significantly higher than comparable PETG. The material is non-marring, and promises to be easy to print, machine and finish. Smooth surface properties achievable in Ultrafuse Z PCTG help to prevent latent failures in end-use parts.

Essentium was brought in to help produce this filament due to its expertise in creating the Z range of ESD safe filaments. In order to maintain the mechanical and ESD dissipating properties of Ultrafuse Z PCTG, the filament should always be kept dry. BASF also recommends the material be stored between 15°C and 25°C in the filament’s originally sealed package.

Flexible material for open platform 3D printers

Ultrafuse TPU 80A LF is a highly flexible material made to be printable on a wide range of open platform 3D printers with a heated bed. The recommended nozzle temperature for this filament is 233 – 240 °C, with a bed temperature of 50 – 80 °C. In terms of settings, the company recommends a print speed of between 18 and 25 mm/s.

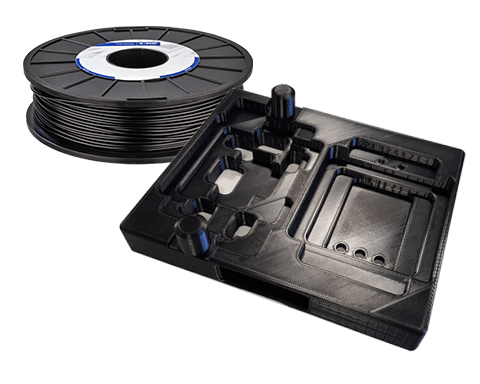

The tensile strength of Ultrafuse TPU 80A LF (3D printed as a flat dogbone) is 22 MPa. The strain at break of this same sample is 640%. At 100% elongation the material shows 8 MPa of stress and, at 300%, 13 MPa. It has good chemical and abrasion resistance. According to Innofil3D Ultrafuse TPU 80A LF is also “One of the first flexible filaments designed to work in bowden type extruders.” Its flexibility and toughness makes its suitable for use in place of springs. It is also useful for making seals, gaskets, plugs, suction cups, bumpers, vibration absorbers and insulation mounts. Innofil3D states, “No other filament on the market can match the printability of this extremely flexible filament.”

Which is your Material Company of the Year? Vote now in the 2019 3D Printing Industry Awards.

For all of the latest material releases and news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook. Looking for something new? Join 3D Printing Jobs now and advertise to attract new talent.

Featured image shows Ultrafuse TPU 80A LF and a 3D printed part. Photo via Innofil3D