Leading industrial 3D printer provider ExOne has announced a collaboration with Sandvik Additive Manufacturing to advance its binder jet 3D printing process. Both companies will work towards optimizing the use of metal powders with binder jet 3D printing, with ExOne aiming to offer its industrial customer base an improved binder jet processing solution with the collaboration.

John Hartner, Chief Executive Officer, ExOne, commented on the new program, “We are excited to announce our material collaboration partnership with Sandvik Additive Manufacturing. Sandvik is a world class engineering company with extensive knowledge of materials and their applications to various industries.”

“We look forward to advancing ExOne’s binder jetting process with this new collaboration and creating new solutions that enable broader customer adoption.”

Combining ExOne binder jetting with Sandvik material expertise

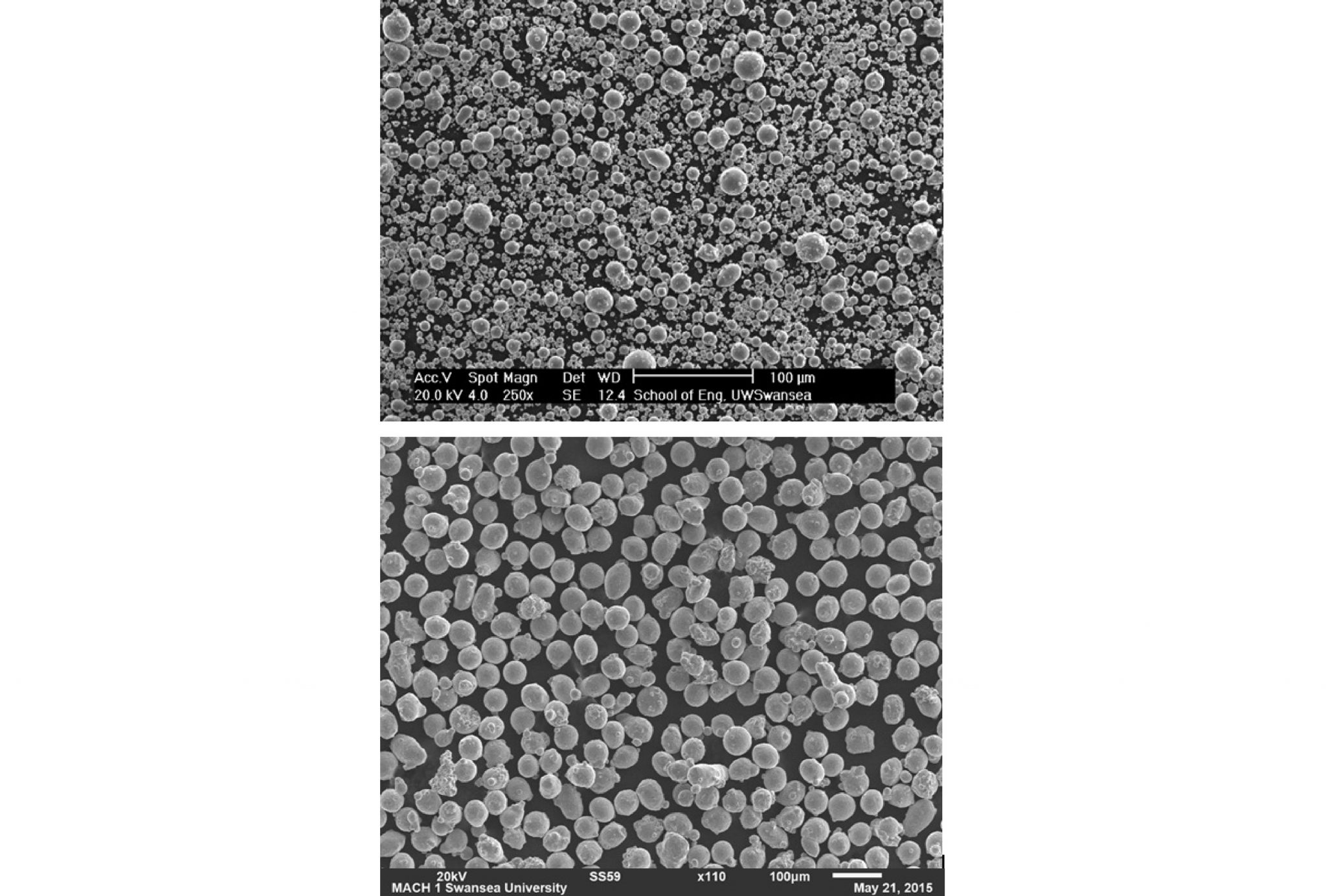

The collaborative program will center on qualifying and optimizing Sandvik’s Osprey metal powders with ExOne’s binder jetting machines. Both companies will study how the powder and binder jetting technology interact with one another, as well as developing the 3D printing process settings. Furthermore, ExOne and Sandvik Additive Manufacturing will create post-processing heat treatments for stainless steels, tool steels and nickel alloys, before moving on to various other materials.

ExOne identified Sandvik Additive Manufacturing, the AM arm of Swedish engineering group Sandvik, to help develop its binder jetting process due to the company’s capabilities in materials technology, metal powders, different AM-processes for metals and post-processing technologies. Sandvik recently, and effectively, demonstrated its advanced production techniques, and will leverage its expertise across the additive manufacturing value chain, from metal powder to finished components, in its material collaboration with ExOne.

“This material collaboration will strengthen our ongoing R&D cooperation with ExOne even further,” stated Mikael Schuisky, VP and Head of R&D and Operations, Sandvik Additive Manufacturing. Sandvik currently has multiple ExOne binder jetting machines in its portfolio, as well being a beta customer of ExOne’s new X1 25PRO, set to be showcased at RAPID + TCT this week. Schuisky continues:

“It also offers great opportunities to qualify our leading Osprey™ metal powders for the ExOne platform, to enhance end customer productivity and product performance.”

Developing binder jetting 3D printing

Recently, ExOne has made strides towards developing and advancing its binder jet 3D printing technology.

The new X1 25PRO is its latest metal binder jetting additive manufacturing system, utilizing the metal injection molding (MIM) powder-handling capabilities of the company’s INNOVENT+™ research 3D printer. It is leading the charge for ExOne among burgeoning binder jet competition across the industry.

Earlier in May 2019 the company revealed it was collaborating with Oak Ridge National Laboratory (ORNL) to develop a new binder jet technology benefiting both sand and metal 3D printers. The two organizations have been working together on binder jetting technology since 2015. Rick Lucas, ExOne’s Chief Technology Officer, comments:

“We believe these collaborative efforts will effectively and efficiently result in the establishment of new materials, binders and process developments, retaining our significant edge over competitors and other technologies in the industrial manufacturing space”.

You can vote for the ExOne X1 25PRO in the third annual 3D Printing Industry Awards, and view the other nominees. Help decide this year’s winners now.

Keep up to date with RAPID + TCT this week by subscribing to the 3D Printing Industry newsletter, following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a 3D binder jetting print head. Photo via ExOne