Researchers from the University of Delaware (UDEL) are using the XJet Carmel 1400 3D printer to develop novel 5G antennas.

XJet, the Israeli 3D printing company behind NanoParticle Jetting (NPJ), made the announcement of this collaboration at RAPID + TCT earlier this week. Hanan Gothait, CEO at XJet said, “The University of Delaware’s application of NanoParticle Jetting technology for antennas is truly pioneering.”

“5G is expected to bring about a true revolution in wireless technology and with it the connectivity to support everything from autonomous vehicles and smart cities to long-distance surgery, live-streaming virtual reality and the prospect of a limitless ‘Internet of Things’.”

3D printing 5G antennas lenses

5G signals, or fifth generation cellular network technology, are said to deliver data 10-20 times faster than 4G and 3G. However, due to its sensitivity to objects, 5G signals need a vast increase in the number of antennas.

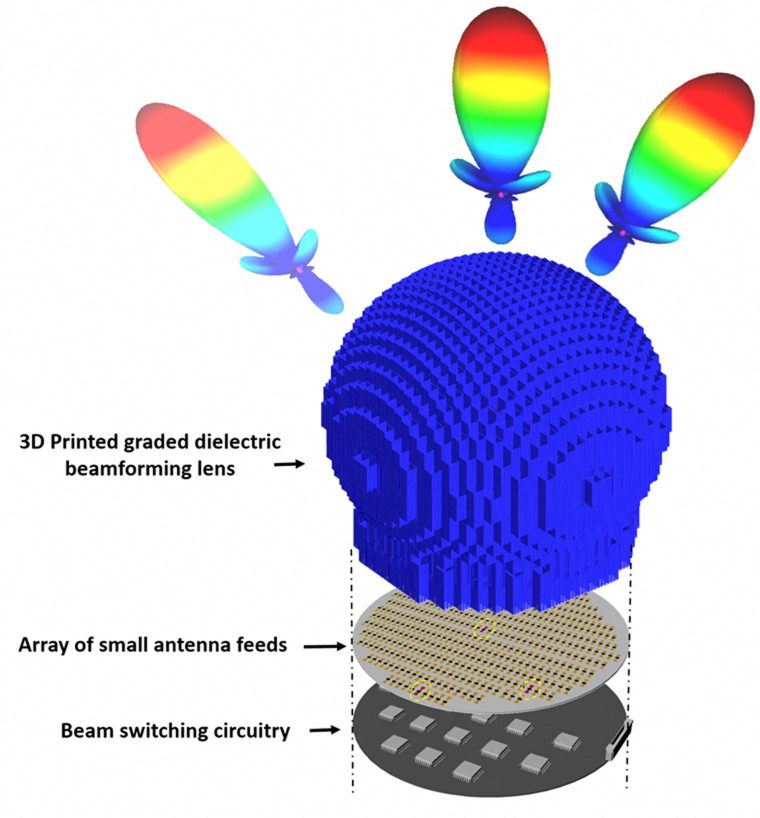

Mark Mirotznik, Professor of Electrical Engineering, UDEL, and his research team developed special software and algorithms to design small, lightweight, and cost-effective 5G antennas, known as Passive Beam Steering. To manufacture lenses with the complex structure, small channels and material properties for the novel antennas they sought XJet’s NPJ technology.

“Discovering XJet NanoParticle Jetting was a real lightbulb moment for us. In one stroke, it solved our previous frustration in achieving both the material characteristics combined with the geometric properties essential to our solution,” added Professor Mirotznik.

Passive Beam Steering

Professor Mirotznik continued, “[It’s] the only process capable of producing the inner walls of each channel with the accuracy and smoothness required to retain wave direction – but in ceramic.”

“XJet’s ceramic is an isotropic, 100% density ceramic with the right dielectric constant, which does not ‘absorb’ and weaken signal. Quite literally, any tiny variation in tolerance could lead to the diversion of the signal to the wrong place, and that couldn’t be afforded.”

The development of antennas took place at Youngstown State University (YSU), Ohio. Professor Eric MacDonald, Friedman Chair for Manufacturing, YSU, explained, “We carried out research to establish the nature and properties of XJet printed Zirconia. This suggested the crystal structure of the prints are nearly even.”

“This opens the potential for 3D printing of a variety of microwave devices including antennas, lenses, and filters. Two simple dielectric resonator antennas were demonstrated with the material, showing that the measured material properties can indeed be used for accurate design of such devices with electromagnetic simulation tools.”

The XJet Carmel 1400 3D printer is also being used by Marvel Medtech, a Wisconsin-based medical device manufacturer, to innovate breast cancer treatments.

Don’t forget to vote for the 2019 3D Printing Industry Awards.

Subscribe to our 3D Printing Industry newsletter and follow us Facebook and Twitter for the latest additive manufacturing news.

Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

Featured image shows a digital demo of XJet’s trademark NanoParticle Jetting metal 3D printing process. Image via XJet NPJ.