There is now just over one month to go until the Cobo Center in downtown Detroit opens its doors on the RAPID + TCT 2019 additive manufacturing exhibition. Already, 3D Printing Industry has reviewed the schedule for this year’s event which has a strong automotive track. Since then though, various companies have started to share details about what they will be bringing to the show.

Expected to attract a crowd of around 6,000 people, RAPID + TCT 2019 will take place from May 20 – 23. Here we have some previews of upcoming exhibits from voestalpine, Optomec, DuPont, XJet, Lubrizol and Dow, including an update from show organizer SME.

SME brings 3D printer search engine to show floor

A new feature coming to the showfloor at RAPID + TCT 2019 is the Interactive RAPID AM Portal (iRAMP). Provided by American manufacturing association SME, iRAMP kiosks will be dotted around the hall, enabling manufacturers to identify the right 3D printing equipment for their requirements.

More than simply a “nice feature” of the show though, feedback generated through the use of these kiosks will be used to help build a better platform for determining technical and mechanical feasibility.

In the official announcement on the search engine from SME, the association states, “An AM equipment repository with searching ability is a foundational capability for advancing AM adoption. But iRAMP’s vision extends beyond that.

“AM adoption depends on these fundamental questions: “Can I Make It?” (technical feasibility) and “Should I Make It?” (economic feasibility)” – two question that is the core of its future development.

Lookout for signposts leading to SME iRAMP kiosks.

Hands-on 3D printing experience at XJet

Also embracing interactivity at this year’s event will be Israel metal and ceramic 3D printer developer XJet. Alongside a range of applications for the company’s Carmel machine series, XJet will also be hosting a ‘support removal clinic’ at its booth. The company has also recently reinforced its customer support within the region.

XJet CBO Dror Danai, comments, “XJet is all about pushing the boundaries of what is achievable with additive manufacturing technology, and at RAPID + TCT we have some fantastic demonstrations of this.”

“This year our participation is about showing the US market what NanoParticle Jetting technology can do for the first time in ceramic and metal AM.”

See XJet at RAPID + TCT 2019 on booth 1103.

Liquid Additive Manufacturing of silicone at Dow

American multinational chemical corporation Dow will be exhibiting 3D printer materials at RAPID + TCT 2019 with guest R.D. Abbott Co., Inc., an elastomer supplier.

Dow SILASTIC™ 3D 3335 liquid silicone rubber will be applied by R.D. Abbott to 3D print on a German RepRap L280 Liquid Additive Manufacturing (LAM) 3D printer.

See the exhibit at booth 1673.

DuPont to launch new 3D printer materials

On a separate booth DuPont Transportation & Advanced Polymers, a business unit of DowDuPont Specialty Products, will be launching a new line of semi-crystalline 3D printer materials.

High performing in mechanical toughness, these materials, according to Dupont, “will offer customers greater manufacturing agility by enabling a seamless transition across different 3D printing scenarios while maintaining consistent properties.”

Jennifer L. Thompson, Ph.D., R&D programs manager for DuPont Transportation & Advanced Polymer, will give a presentation on the materials on May 23, at 10:15 a.m. EDT.

To learn more visit booth 552 from 22 May 2019.

Voestalpine shows what metal additive is capable of

On behalf of steel technology company and capital goods group Voestalpine, the Voestalpine AG High Performance Metals Division will be demonstrating its additive manufacturing capabilities at the show.

According to Martin Beaton, President of voestalpine Additive Manufacturing Centers & Vice-President of Innovation & Value-Added, North America, “Our aim has always been to help our customers grow and to utilise the latest advances in technology to achieve their growth goals.”

“We hope that the show will help support this goal and look forward to seeing you in May.”

The company has metal additive manufacturing capabilities and develops its own powdered and wire-feed material on site.

Visit Voestalpine at booth 757.

Lubrizol’s bio-based TPU

The Lubrizol Engineered Materials division of Ohio specialty chemicals corporation Lubrizol, is to showcase its range of 3D printer materials in Detroit next month.

Special focus will be paid to the company’s Estane® 3D ECO TPU, an thermoplastic polyeurethane made from approximately 30% bio-based content.

“Estane® 3D ECO TPU is part of our strategy to build our FFF portfolio based upon customer and market requirements, ensuring same or superior level of properties both for prototype and mass production opportunities, along with the renewability feature,” comments David Pascual, Global 3DP Marketing Manager at Lubrizol Engineered Materials.

“Results are overwhelming, and we will continue to strive to increase our polymer portfolio for 3D printing.”

Find Lubrizol Engineered Materials at booth 133.

Demo Optomec’s latest LENS hybrid system

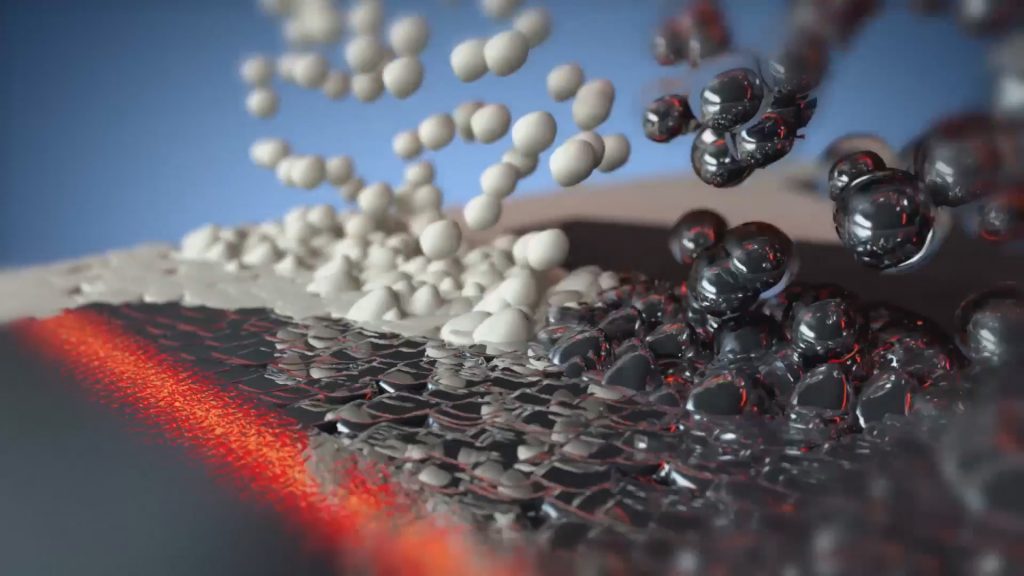

And finally (for this update at least) Albuquerque 3D printed electronics and LMD specialist Optomec is to demo its latest machine, the LENS 860 Hybrid Controlled Atmosphere System, at RAPID + TCT 2019.

You can find this machine and more at Optomec’s booth, number 517.

3D Printing Industry will be reporting live from RAPID + TCT 2019. To stay up to date with all event’s announcements, presentations and exhibits, subscribe to our newsletter. You can also join us on Facebook and Twitter. Looking for a job in the industry? Visit our 3D Printing Jobs board.

Decide this year’s winners of the 2019 3D Printing Industry Awards.

Featured image shows Optomec LENS technology. Clip via Optomec