German RepRap, manufacturers of FFF 3D printers, has introduced its first Liquid Additive Manufacturing (LAM) production-ready 3D printer, the L280. The company stated:

“LAM is a very interesting 3D printing process because it works with a material that is in a liquid form that is vulcanized under heat exposure to its final form, contrary to the FFF technology.”

“In this way, objects can be produced that have the same properties as injection-molded parts – a clear advantage because insights from the 3D printed prototype can be transferred directly to injection-molded serial parts.”

Liquid Additive Manufacturing

Last year, German RepRap presented the first prototype LAM system at Formnext in Frankfurt, to demonstrate how liquid materials, such as Liquid Silicone Rubber (LSR), can be processed in LAM 3D printers. Differing from FFF hardware, the LAM 3D printer deposited layers of silicone from a syringe whilst using thermal energy to ensure crosslinking.

During this process, the application direction and the vulcanization, a chemical conversion process used in the Digital Light Processing (DLP) at the macromolecular level, can be altered. As a result, parts can be made stronger when compared to injection molding.

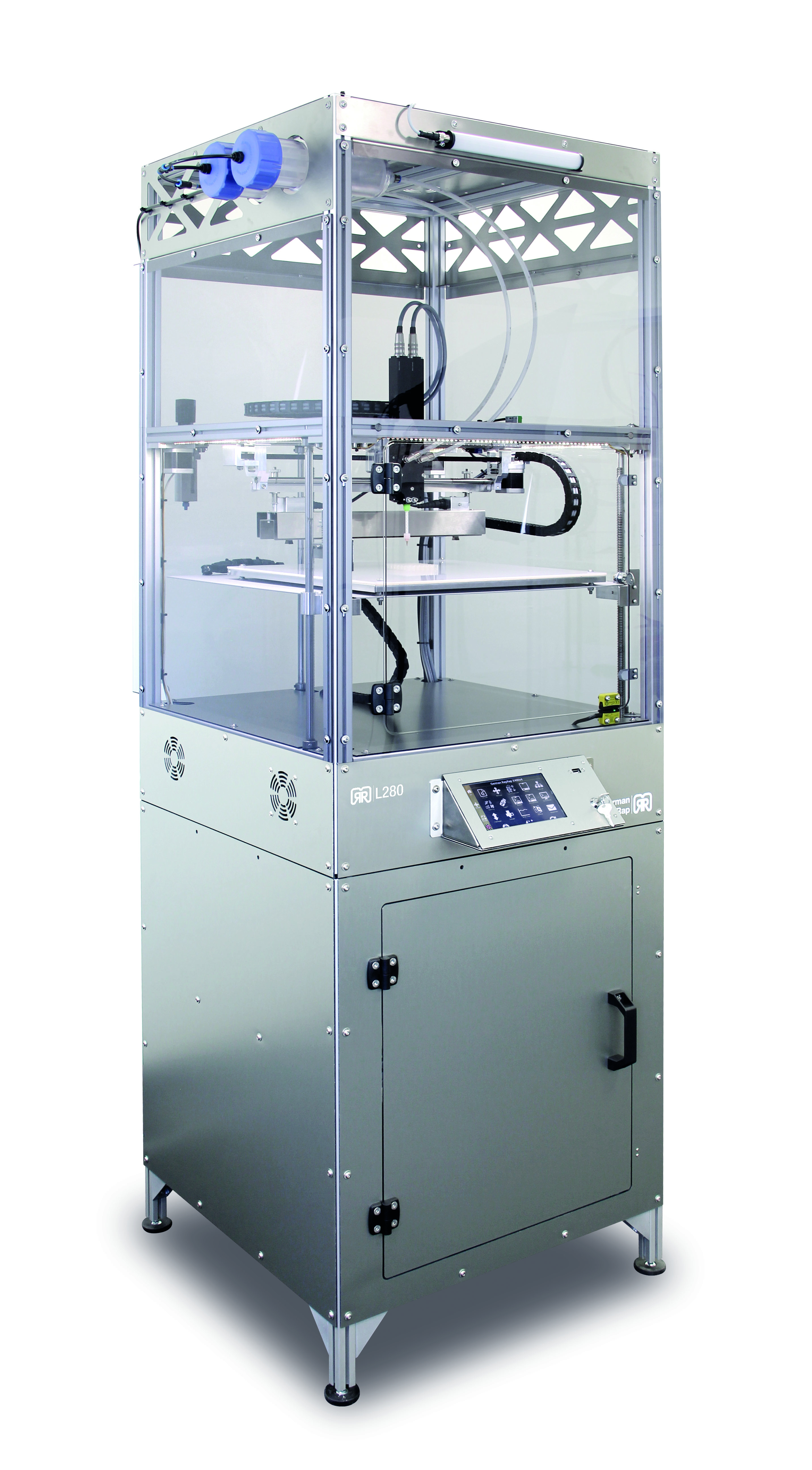

The L280 3D printer

The L280 provides a heated print bed and high-temperature halogen lamp to enable optimal cross-linking during the LAM process for durable parts. In addition, the printer features a pressure chamber of 280 x 280 x 200mm (X x Y x Z) and network connectivity. The L280 also includes safety technology which monitors the curing process and immediately stops the process according to irregularities.

Moreover, a maintenance contract and a professional on-site service are available as an option from trained technicians using the L280. According to German RepRap, the L280 3D printer has “proven its reliability in continuous operation in extensive tests and pilot applications in practice.”

| Pressure chamber * (XxYxZ) | 280 x 280 x 200 mm |

| Print speed | 10-150 mm / s |

| Traversing | 10 – 300 mm / s |

| Repeat accuracy * (X / Y) | +/- 0.1 mm / s |

| Layer thickness (min.) | 0.22-0.9 mm |

| Materials | EVOLV3D LC 3335 Liquid Silicone Rubber (LSR) |

| Nozzle Options | 0.23 | 0,4 | 0.8 mm |

| Temperature pressure plate | 110 ° C |

| Options | Maintenance contract, barrel removal |

| Data exchange | Data transfer with USB stick |

| Software | Simplify3D software |

| Operating voltage | 230 VAC |

| Ambient temperature | 15-26 ° C |

| External dimensions (WxDxH) | Printer with cartridge system: 700 x 700 x 2040 mm

Printer with barrel removal: 700 x 700 x 2260 mm |

| Mass | 120 kg (without sampling system) |

| Technology | LAM |

German RepRap will debut the L280 3D printer at Formnext in Frankfurt, where 3D Printing Industry will be reporting live.

Keep up with the latest additive manufacturing news by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace or seeking new talent? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the LAM process within the L280 3D printer. Photo via German RepRap.