XJet, an Israeli 3D printer manufacturer, has sold a Carmel 1400 3D printer to Marvel Medtech, a Wisconsin-based medical device manufacturer specializing in cancer treatment.

Dror Danai, CBO of XJet, said, “With over 500,000 women dying from breast cancer every year, and with 40,000 of those in the USA alone, Marvel Medtech’s solution has truly transformative potential in the healthcare industry.”

“We were delighted to offer the Carmel 1400 in solving their production issues, and we are very proud to play our part in bringing this life-saving technology to market.”

Guided MRI for cancer treatment

Marvel Medtech has developed an interactive MRI system called Solada. It is a robotic system which allows intervention inside the MRI imaging bore. Researchers have classified these kinds of robots as surgical computer-aided design and computer-aided manufacturing (CAD/CAM) robots, distinct from ‘surgical assistant robots’.

A CAD/CAM robot is a surgical guidance system which requires human intervention. For example, in case of a biopsy, despite the guidance of a robot the biopsy needle will still have to be probed by a physician.

Marvel Medtech calls Solada an interactive Magnetic Resonance Imaging Guided Intervention (iMR-IGI). The device enables real-time monitoring and guidance of probes for surgical procedures inside the MRI scanner.

For now, Marvel Medtech is focused on developing Solada for breast biopsy only. So far, the medical company has raised $2,500,000 which includes $2 million in grants from the National Cancer Institute (NCI) and National Institutes of Health (NIH).

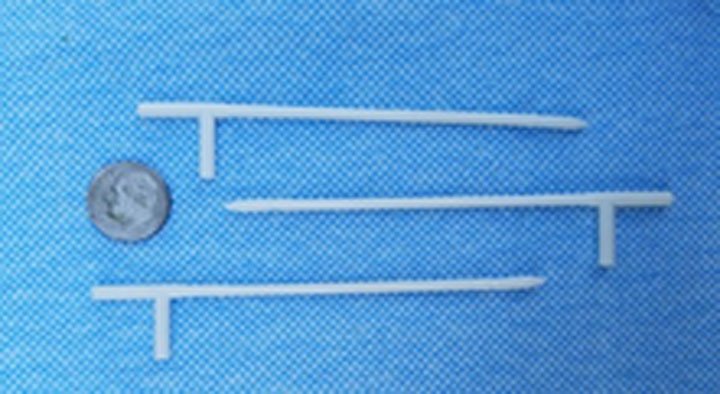

3D printed cryotherapy probe

Marvel Medtech acquired the Carmel 1400 machine because it is capable of 3D printing precise and complex ceramic objects with soluble supports. The Carmel 1400 machine will be used to 3D print a ceramic cryotherapy probe for the Solada robotic system. The probe will help destroy tumorous breast cancer cells.

Ray Harter, President of Marvel Medtech, explained, “The tools used inside an MRI scanner must be compatible with strict safety guidelines, and crucially, not disrupt image quality. Because they are one of the most electrically insulating materials, ceramics are an ideal material to achieve this.”

Harter continued, “However, we were unable to find a ceramic-based 3D printer able to accurately and cost effectively produce our ceramic probe. This is why we are adopting XJet’s Carmel 1400 solution.”

Fight against cancer

3D printing in the medical field is having a significant impact, especially in the fight against cancer. Treatments that were limited before due to complex tools not being available are now more effective. Such examples include 3D printed bolus for administering medicine, full-body phantom and presurgical models.

Now, Xjet’s Carmel 3D printer will make another marvel in medicine achievable which once was perhaps improbable, if not impossible.

Danai said, “This application is a great example of how our unique ceramic 3D printing technology can enable manufacturers to overcome the limitations of traditional ceramic production. Indeed, we believe that XJet NPJ opens the door for the invention and production of many new products and tools to answer some of mankind’s biggest challenges, and we’re excited to see how it will impact our lives in the future.”

XJet is at RAPID + TCT 2019. Visit booth 1103 to see what the Carmel 1400 3D printer can do.

Vote now for upcoming 2019 3D Printing Awards in the category of 3D printing for a better world.

Once again. like previous year, we are covering all the latest news from RAPID + TCT, subscribe to our 3D printing newsletter and stay on top of the news. Also, join us on Facebook and Twitter for live updates.

Visit our 3D Printing Jobs board to start a career in additive manufacturing.

Featured image shows a gear 3D printed on Carmel 1400. Image via XJet/Twitter.