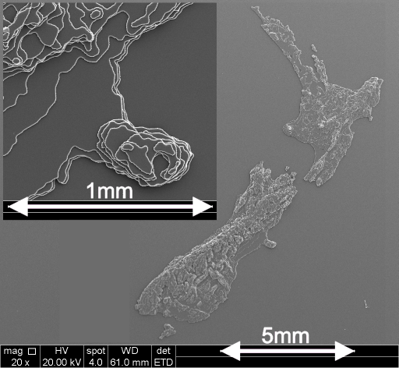

Callaghan Innovation, a government agency supporting technology businesses in New Zealand, has developed new micro 3D printing technology enabling the production of structures smaller than a strand of human hair.

MicroMaker3D, Callaghan Innovations additive manufacturing arm, has patented Laminated Resin Printing (LRP) – a novel 3D printing technology for rapid prototyping of high-resolution microscale structures which was presented at RAPID + TCT last week.

Neil Glasson, the lead engineer at MicroMaker3D, said, “We recognized the growing demand for miniaturized structures – the vital components in an increasing number of devices and manufacturing applications – and then we went about finding a way to produce these structures in a less costly way.”

Laminated Resin Printing

Callaghan Innovation introduced LRP as a unique form of microfabrication n November 201,. Upon its debut, Andrea Bubendorfer, co-inventor of LRP, explained, “Microfabrication – the production of very small high-value devices – is an export industry for New Zealand. Until now, however, making these miniature structures has been slow and expensive.”

At this time, LRP attracted a further $684,000 of pre-seed funding from public research organization KiwiNet. According to Glasson, MicroMaker3D is using LRP to produce dense, detailed objects as small as 5 μm. The technology can be used to fabricate both single and multi-layer structures with extreme thermal and chemical resistance. This includes substrates including paper, fabric, silicon wafers, and PCBs.

Miniaturization and additive manufacturing

Cath Andrews, Senior Business Development Manager at Callaghan Innovation, stated, “LRP was developed to address a growing market need to rapidly produce microscale structures in an efficient, convenient and cost-effective way.”

“It could open up miniaturization as a new high-value application in additive manufacturing, an industry that already exceeded $US7B in 2018. So, it’s not surprising that with its development it’s attracting investor and end-user interest.”

Presently, Callaghan Innovation is seeking to commercialize LRP technology globally for researchers, developers and manufacturers to create a wide range of submillimeter 3D printed structures for applications such as electronics, wearables, sensors, and IoT devices.

It’s your last chance to tell us who you think are the leaders of additive manufacturing. Vote for the 2019 3D Printing Industry Awards.

For more on additive manufacturing news, subscribe to our 3D Printing Industry newsletter and follow us Facebook and Twitter.

Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

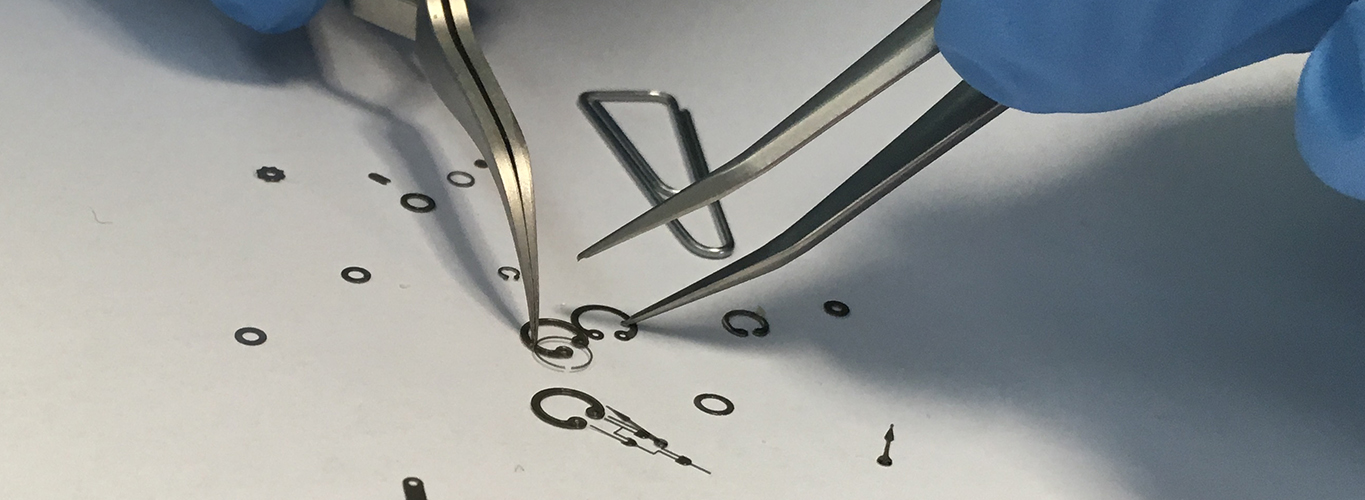

Featured image shows 3D printed microstructures. Photo via Callaghan Innovation.