Additive Manufacturing Technologies (AMT), the award-winning Sheffield-based OEM, is at RAPID + TCT 2019 this week showcasing advanced post-processing technology for 3D printing. AMT will introduce two of its latest machines at the show in Detroit, including the latest post-process coloring system.

AMT CEO Joseph Crabtree, said, “We are looking forward to a busy week here at RAPID in Detroit, meeting with customers and sharing our vision with potential new partners.”

Boundary layer automated smoothing technology

Founded in 2017, AMT manufactures automated post-processing systems for 3D printing.

PostPro3D is AMT’s first post-processing system. It uses a proprietary method called Boundary Layer Automated Smoothing Technology (BLAST), which was developed at University of Sheffield‘s Advanced Additive Manufacturing (AdAM) Centre, under the name PUSh. This technology was commercialized by AMT as BLAST.

The BLAST process supports various 3D printing technology such as powder bed fusion, HP Multi Jet Fusion, High Speed Sintering, and FDM/FFF. It is compatible with polymers commonly used in industrial 3D printing such as Nylon 6, 11, and 12, ULTEM, PMMA, TPU, and TPE. According to AMT, the BLAST finished parts are close to injection molding.

Furthermore, parts processed with PostPro3D are ISO 10993-5, ISO 10993-1, and ISO 10993-12 certified, which means they are not toxic to cells (cytotoxicity). Therefore, these parts can be certified for medical use.

Processing beyond borders

The PostPro3D has a process chamber of 600 x 400 x 400 mm. The machine is connected through a 3G network for remote monitoring and diagnostics. It takes approximately 90-120 minutes to process the parts in PostPro3D.

In order to commercialize its systems in the U.S and EU, last year, AMT collaborated with Mitsubishi Electronics to certify the PostPro3D with a UL and CE marking. PostPro3D is built with various components from Mitsubishi Electric, which include power supply, FR-D700 frequency inverter drive, and an optional MELFA RV series robotic arm, among several other parts.

Color post-processing

At this weeks show AMT will showcase two new products: PostPro3DColor and PostPro3DMini.

The PostPro3DColor system, along with post-processing 3D printed parts, is also capable of coloring them in a single step. The machine uses a cartridge which diffuses the targeted color as mist inside the chamber of the machine. The colored particles attach to the component while it smooths.

PostPro3DMini, on the other hand, is a smaller version of the original PostPro3D with a process chamber of 300 x 350 x 300 mm. The machine is priced at $32,000 and is available to pre-order with expected delivery in Q4 2019.

RAPID + TCT 2019 visitors can see the full range of AMT’s machines at booth 656. On 21 May, AMT’s Executive VP Americas, Luis Folgar, will also give a talk on the importance of automated post-processing solution in the additive industry.

Crabtree added, “Visitors to the AMT booth at RAPID + TCT are welcome to discuss their automated post-processing needs, investigate the PostPro3D range, including full specifications, and discover the advantages of implementing a true Digital Manufacturing System in collaboration with AMT.”

Vote now in the category of OEM of the year for 2019 3D Printing Awards.

3D Printing Industry is on the ground covering all the exciting news from America’s largest 3D printing shows, RAPID + TCT 2019. Subscribe to our 3D printing newsletter to stay up to date and join us on Twitter and Facebook.

Visit our 3D printing Jobs page to start a career in manufacturing.

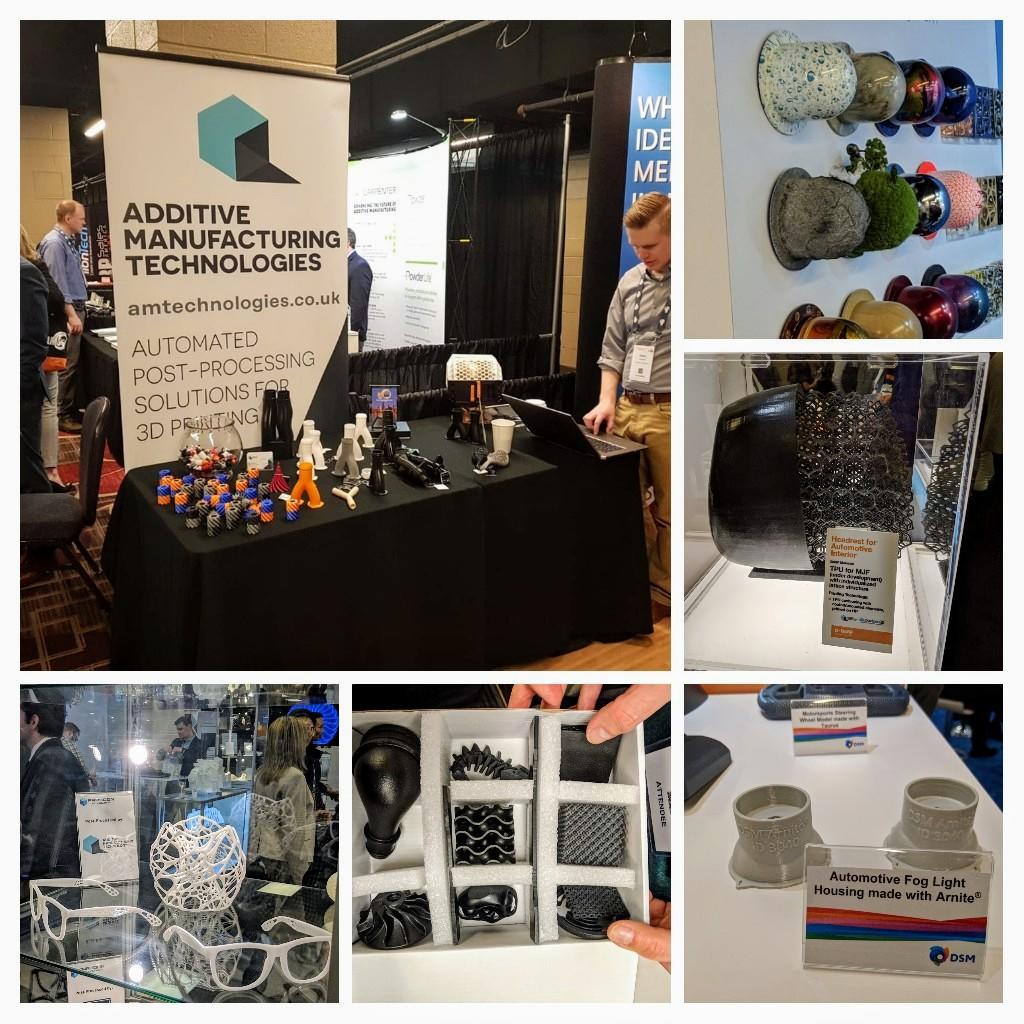

Featured image shows 3D printed parts post-processed with AMT’s PostPro3D. Image via AMT.