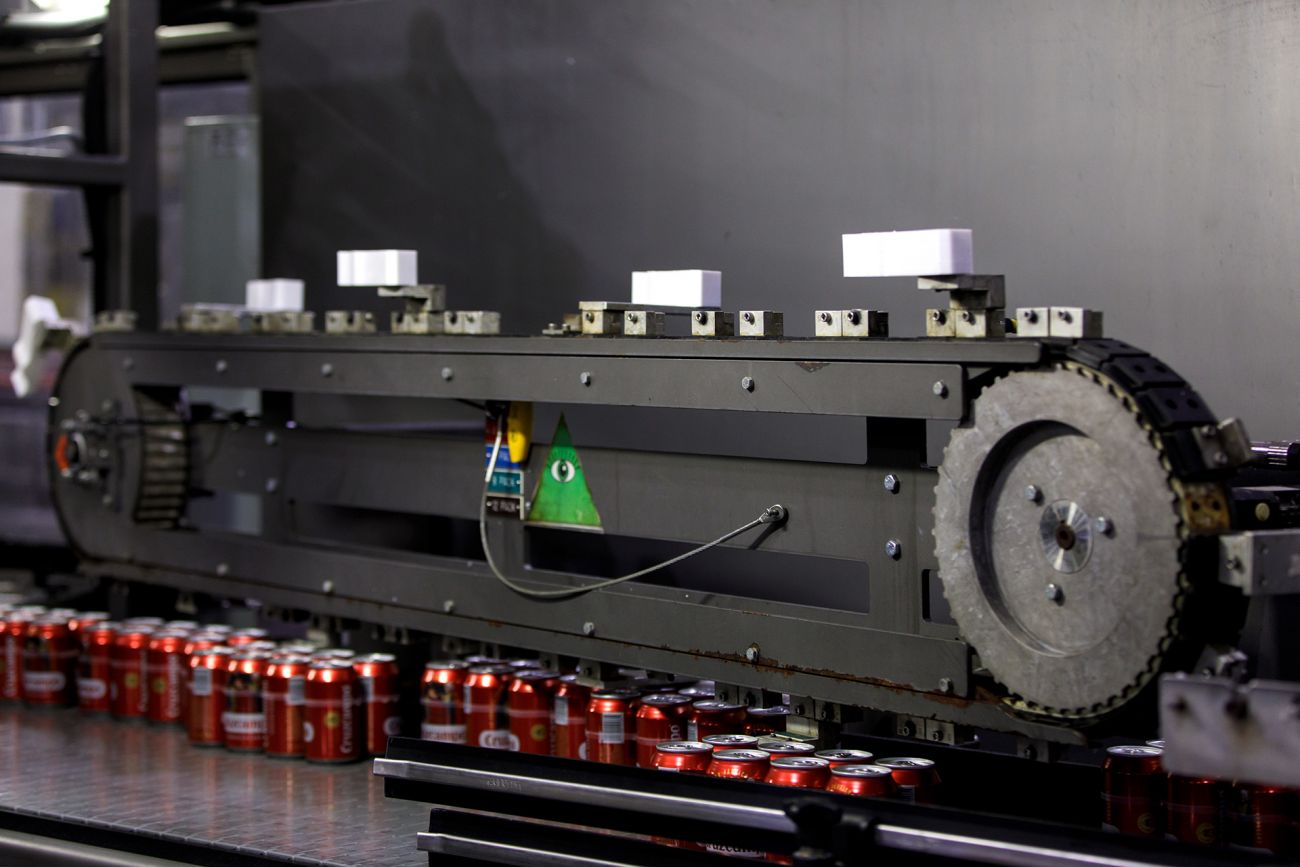

Dutch brewing company Heineken is using Ultimaker 3D printing technology to produce functional end-use parts for its beer production line in Seville, Spain.

With the aid of Ultimaker S5 printers, Heineken is now able to print its own parts on-demand, reducing the need for outsourcing. The company claims this increases production uptime and saves around 80% in production costs.

“We’re still in the first stages of 3D printing, but we’ve already seen a reduction of costs in the applications that we found by 70-90% and also a decrease of the delivery time of these applications of 70-90%,” said Isabelle Haenen, Global Supply Chain Procurement at Heineken.

“Local manufacturing helps us a lot in increasing uptime, efficiency and output. We use 3D printing to optimize the manufacturing line, create maintenance and quality control tools, and create tools for our machines which help us increase safety for our people. I think there will be even more purposes in the future.”

Potential of 3D printing in large scale beer production

Founded in 1864 in Amsterdam, Heineken now owns over 165 breweries in more than 70 countries. The Sevilla brewery alone produces several brands of Heineken-owned beers, amounting to around 500 million liters of beer per year. With production operating at such scale, any stoppages could have potentially costly implications.

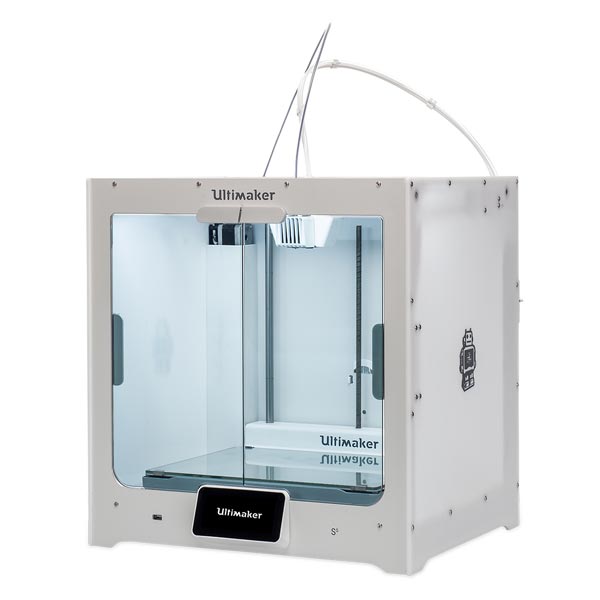

Spurred on by the potential gains of additive manufacturing, Heineken began using the Ultimaker 2+ in a limited capacity last year – mainly for safety applications. Its engineers then began experimenting with the Ultimaker S5 3D printer, a larger, enterprise-ready machine.

The S5 is specifically designed for professional manufacture of tools and end-use parts. Building on the Ultimaker 3, the S5 features a larger build volume and a range of ease-of-use enhancements. It uses materials such as Tough PLA, Nylon, and semi-flexible material TPU 95A.

Tapping into 3D printing technology

The engineers quickly learned that they could save a lot of time and money using the S5 to creating custom optimized functional parts for its production line. By 3D printing these parts on-demand, the company found that it could save money while avoiding operational downtime as there was no need to have an inventory and no need to wait for part deliveries.

Over the course of a year, Heineken also identified several parts which could take advantage of 3D printing. For example, a can pusher, used to reject and direct bottles, previously produced out of metal using conventional manufacturing would cost substantially more and have a longer lead time.

Similarly, a pack spinner, used for rotating bottles on the production line, cost a similar amount to produce and have an average lead time of using conventional manufacturing in the same area as the can pusher.

On the more costly end, safety latches, preventing the machines operating during maintenance, in their thousands with an average lead time of weeks could be produced by the S5 for hundreds with a lead time of days.

Jos Burger, CEO of Ultimaker commented on Heineken’s integration of its 3D printing technology, he said, “Every company has its own unique challenges in the production process, which is why the ability to create custom solutions straight from the factory floor is such a game-changer for the manufacturing industry.”

He added, “Heineken is a prime example of a company that’s utilizing the Ultimaker S5 as an all-purpose manufacturing machine. We have enjoyed watching the use case evolve over the past year, from safety applications to the creation of fully functional parts for machines that lead to significant savings, and we cannot wait to see what they come up with next.”

As the successful experimental phase draws to a close in the Seville brewery, Heineken now hopes to start up multiple projects to apply these functional applications and scale them to its global operation.

Ultimaker is at RAPID+TCT 2019 in booth #427.

Vote for your 3D Printing Innovation of the Year in the 2019 3D Printing Industry Awards.

Keep up to date with all the news from Rapid this week by subscribing to the 3D Printing Industry newsletter, following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an Ultimaker S5 3D printer. Photo via Ultimaker.