UNYQ, a San Francisco-based assistive device developer, has teamed up with IKEA to produce 3D printed products for the gaming community.

“The gaming community has been overlooked for a long time when it comes to furniture and accessories that are functional and customized, as well as aesthetically suit individuals’ preferences,” said Eythor Bender, Co-Founder and CEO of UNYQ.

“We have the ability to address the unique needs of these individuals and, in turn, personalize, protect and improve their game.”

Bespoke 3D printed products

Founded in 2014, UNYQ started out manufacturing a range of personalized prosthetic covers for upper and lower limb amputees. More recently, the company has begun developing a ‘total leg’ solution, with a printed socket and foot to compliment its existing products. In the company’s latest range, this expertise has now been transferred to work on specialized gaming products.

Gamers typically spend a large portion of their time stationary, performing repetitive actions, which can lead to massive physical strain on the wrists and spine. Therefore a bespoke, form fitting, product would lessen the potential for injury and improve comfort.

To help understand how best to design a product for the gaming community the company drew on the expertise and input of Stockholm-based Area Academy, an educational e-sport company.

Combining the insights of Area Academy with Carbon’s 3D printing technology, UNYQ and IKEA have developed an initial line of three prototype 3D printed accessories for gamers , named UPPKOPPLA, which means ‘online’ in Swedish.

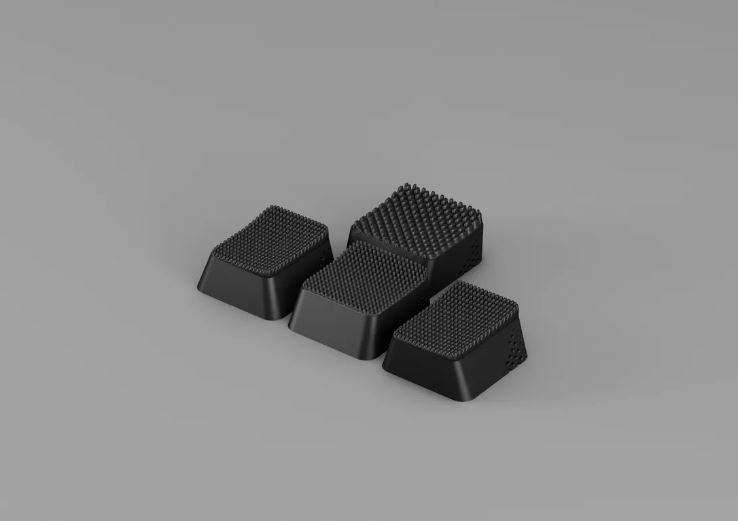

The range includes a biometric wrist support which maintains the correct height of the gamers’ wrist to the keyboard, reducing strain on their tendons. Soft pliable, vented keycaps to make the keyboard feel like a physical extension of a gamers’ fingers. And

a portable mouse “bungee” which clamps the users’ mouse cable in place, preventing tangling and enabling full freedom of movement.

To create the devices, UNYQ used generative design. According to Bender this modeling method “and additive manufacturing process simplifies and shortens value and supply chains, making it easily replicable across different products, more affordable and allowing individuals to partake in the design process.”

3D printed products for gamers

This is not the first time the two companies have teamed up to produce products for the gaming market.

In June 2018 IKEA and UNYQ developed an ergonomic chair for professional gamers, allowing them to sit comfortably for long periods of time. The chair, dubbed the UBIK, used 3D printing and body-scanning to create customized lattice inserts to prop up each sitter in their ideal posture.

Commenting on the extension of their collaboration Michael Nikolic, Creative Leader at IKEA of Sweden, said, “This is an exciting partnership for IKEA. UNYQ has developed a method of creating solutions that fit everyone’s unique needs and tastes, letting customers take design into their own hands.

“It is a great way to give customers exactly what they want, and it also minimizes waste as production is directly aligned with demand and there is no inventory. We are really looking forward to see where this new way of working will take us and are excited to continue to collaborate with UNYQ.”

Currently the collaboration is focused on the gaming market, however the two companies plan to extend the partnership to cover a range of sectors, tapping into ‘underserved’ communities, with varying interests, unique preferences and specific needs.

The UPPKOPPLA collection will be available to order via a smartphone app globally in 2020. Once launched, users will be able to use UNYQ’s photogrammetry, enabled by the user’s phone camera, to create customized versions of the gaming accessories.

Subscribe to the 3D Printing Industry newsletter and follow us Facebook and Twitter for the latest news in additive manufacturing.

Visit our 3D Printing Jobs board to find new opportunities in your industry.

Featured image shows a 3D printed wrist support. Image via UNYQ.