Stratasys has announced a partnership with Don Schumacher Racing (DSR) – the winningest team in the National Hot Rod Association (NHRA), the largest auto racing organization in the world, to accelerate prototyping and new component design.

Based in Brownsburg, Indiana, DSR’s efforts to become more competitive has led to the integration of the Fortus 450mc and F370 3D printers. In doing so, its production arm, Don Schumacher Motorsports, is using 3D printing to accelerate design iterations, workflows and final part production.

“With Stratasys 3D printing in place, anytime a crew chief has an idea for a project or concept part, we can design it, print it out, and test fit and function rapidly at a low cost – whether it’s a prototype or final part,” said Scott Cutler, Senior Manufacturing Engineer, Don Schumacher Motorsports.

“Thanks to 3D printing, we’re able to be more innovative – which equals consistent performance on the track.”

Speeding up race car production

Amongst the developments made at RAPID + TCT last week, Stratasys declared that DSR would join its list of customers using additive manufacturing in competitive and high-performance environments.

As such, DSR, who fields seven professional teams competing in the NHRA Drag Racing Series, is using the Fortus 450mc and F370 3D printers for chassis or weldment fixturing, prototype development, final design proof-of-concept, and finished ultralight usable components.

The 3D printers are currently fully integrated into the team’s fabrication shop and will utilize a variety of materials for strong and flexible parts. This includes Stratasys’ FDM TPU 92A, a durable elastomer material. Pat Carey, Senior Vice President at Stratasys added:

“Competitive motorsports demand technology that can not only handle the design complexity of these environments, but also rapidly create prototypes and parts to withstand the high-performance requirements of racing.”

“Don Schumacher Racing is a great example of the power of additive manufacturing at work – and we’re excited to work alongside the team and tackle the most extreme challenges across their production environment.”

Additive accelerates automotive

DSR is accompanied by several motorsport companies using additive manufacturing technologies from Stratasys. Earlier this month, Stratasys also announced a collaboration with Arrow Schmidt Peterson Motorsports (Arrow SPM), an NTT IndyCar Series racing team, to integrate its 3D printing technology to improve the performance of its vehicles on the race track.

Prior to this, German automobile manufacturer Audi AG expanded production at its Volkswagen Group R8 facility, the Böllinger Höfe, with a separate 3D printing department. This included the adoption of the Stratasys full-color, multi-material 3D printing with the J750 for its product design process.

It’s your last chance to tell us who you think are the leaders of additive manufacturing. Vote for the 2019 3D Printing Industry Awards.

Also for latest additive manufacturing news, subscribe to our 3D Printing Industry newsletter and follow us Facebook and Twitter.

Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

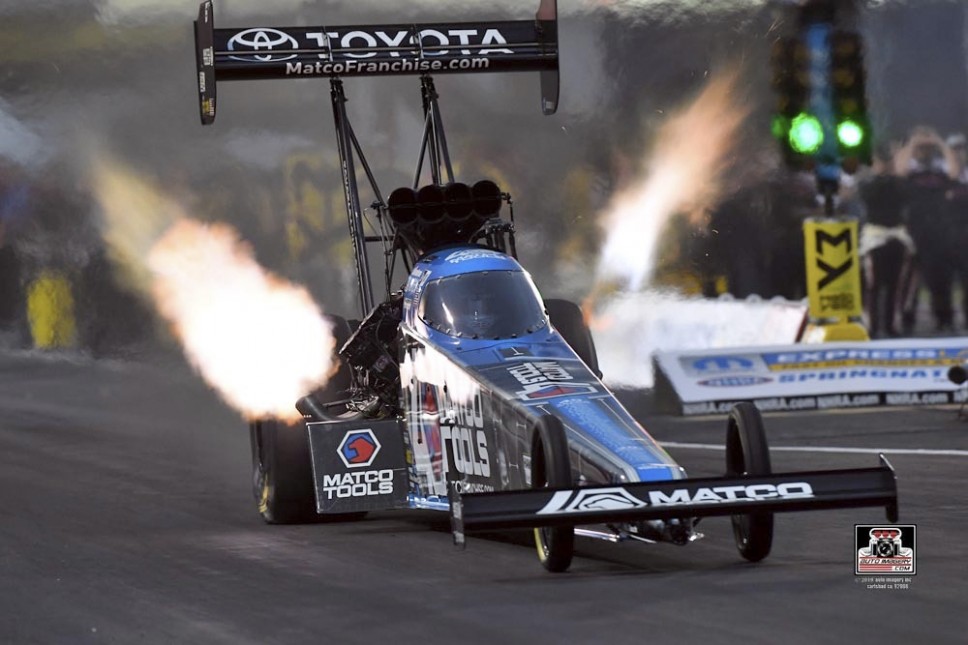

Featured image shows a DSR race car. Photo via DSR.