By using 3D printing, French pharmaceutical company UPSA has made cost reductions of up to 95 percent. The savings come from integrating additive manufacturing into specific processes using a Stratasys Fortus 450mc Production 3D printer. Although the 3D printer was purchased less than a year ago, the savings have already covered the cost of the 450mc.

3D printed parts deliver efficiency savings and weight reductions

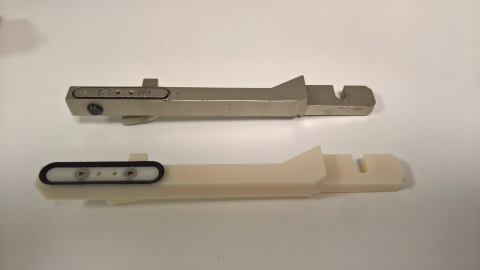

Specifically, UPSA has realised substantial efficiency savings using the 450mc for part replacement. 3D printing has decreased part weight by 70 percent, “reducing machine wear-and-tear, and [having] a big impact on productivity and machine longevity,” according to Mathieu Dumora, Project Manager at UPSA’s Technical and Infrastructure Department.

Dumora explained that heavy cast steel arms, used to open cartons on the production line, are susceptible to distortion and sometimes break under their own weight, requiring lengthy and costly repairs.

The Stratasys’ ABS-M30i biocompatible 3D printing material used can recover from distortions and also be replaced at “minimal cost and [with] a short printing time.” During a year of replacing 55 steel arm parts with ABS-M30i plastic, UPSA has achieved a 95 percent cost reduction per part.

Reducing the labor required to ensure the safety of closure caps

Another application of 3D printing at UPSA is the removal of labor intensive visual inspections of the closure caps on bottles of Efferalgan, its brand of paracetamol. Visual inspections were used to detect particles that pose a risk of contamination to the paracetamol.

A 3D printed device made with the 450mc “sucks and blows air to remove any particles. We test the air suctioned and even sometimes place particles in caps to test efficacy. Thanks to additive manufacturing, we are able to make this solution ourselves and evolve it through development iterations quickly and cost-effectively.”

Simplifying part assembly

UPSA’s design engineers are using the 450mc to reduce the number of parts needed for the camera mounts used to automate the checking of packaging labels. Previously the camera mount used “an assembly of 27 parts, the new design has just two parts, which has seen us enjoy a significant reduction in production time and cost.”

Immediate positive impact of 3D printing

Dumora says that “for those of us who use it, the Fortus 450mc is an absolute work-horse, but it’s immediate and positive impact is ultimately underscored by the fact that in the first year of integrating the machine, we more than made a return on our investment”

Stratasys’ President of Europe, the Middle East and Africa, Andy Middleton said “The speed at which UPSA has successfully integrated our 3D printer within production and realized such a huge quantifiable ROI, is testament to the way this technology can quickly and cost-effectively overcome production-line challenges for manufacturers in most industry sectors.”

Latécoère, a French aerospace manufacturer, has also achieved efficiency savings with 3D printing and the 450mc. Lead times for the production of prototypes have been cut by 95 percent from six weeks to two days. Volvo CE are now 3D printing replacement parts for their entire range of industrial machinery.

Be the first to hear about the latest medical uses for 3D printing. Subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Vote for the Medical, Dental or Healthcare application of the year in the 2018 3D Printing Industry Awards.

Post a job or advance your career in 3D printing, check out the 3D printing jobs board.

Enter the 3D Printing Industry Awards design competition, for the chance to win a Wanhao Duplicator 9 3D printer, sponsored by Protolabs.

Featured image shows Matthieu Dumora, and Frédéric Tremoulet, Head Manager, Technical and Infrastructure Department at UPSA, holding a 3D printed camera mount. Photo via Stratasys.