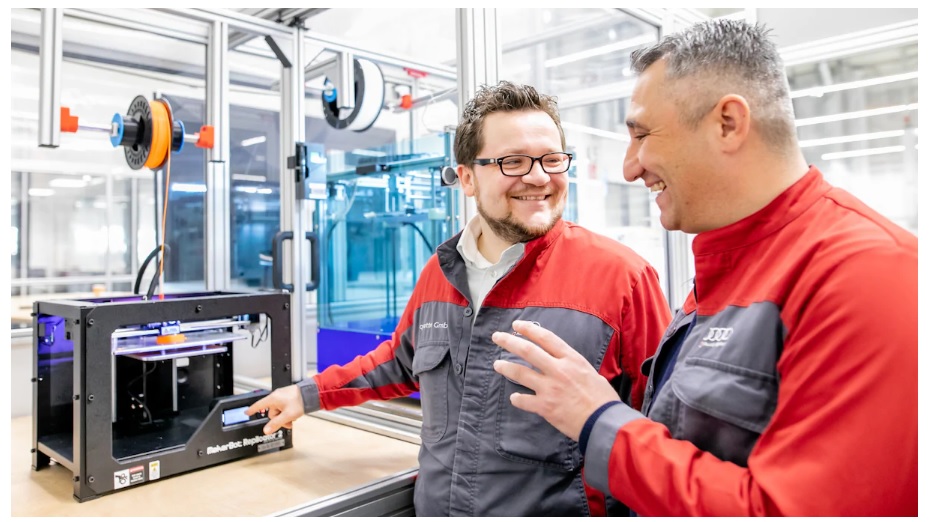

German automobile manufacturer Audi AG has expanded production at its Volkswagen Group R8 facility, the Böllinger Höfe, with a separate 3D printing department. Employees in this new space are creating custom 3D printed parts, including auxiliary tools, to save on maintenance costs.

“When designing a prototype, it is very important to us that we fulfill our colleagues’ wishes exactly,” explained Waldemar Hirsch, Audi Sport 3D printing coordinator at the Böllinger Höfe in Heilbronn, Germany.

“Our goal is to provide our Audi colleagues the 3D printed tool as quickly as possible, thus supporting them in their daily work.”

Accelerating automotive production

Audi’s Böllinger Höfe has been using FFF/FDM 3D printing for five years to print auxiliary tools within the Audi R8 assembly line. Now, with a separate department focused on manufacturing tools to support production, Hirsh and his team hope to teach their fellow Audi employees how to create such 3D printed instruments.

Currently, there are four 3D printers operating in this department on a daily basis; this includes systems from Ultimaker and MakerBot. As well as 3D printed auxiliary tools designed to guide machinery, this new space is additively manufacturing casting molds and safety devices.

Helmut Stettner, Plant Director at the Audi plant in Neckarsulm comments, “By establishing a separate specialist department for 3D printing, we are professionalizing this already successful project. Employees will be able to benefit from the experienced expert team and the custom auxiliary tools in the future.”

This step works towards Audi’s goal of developing a worldwide 3D printing network for Volkswagen, the implementation of which won the company the 2018 3D Printing Industry Award for Automotive Application of the Year.

Audi and 3D printing

In addition to prototyping and tooling, Audi has also implemented metal additive manufacturing for end use car parts. Last year, the Audi Pre-Series Center in Ingolstadt, Germany, continued its collaboration with SLM Solutions to 3D print metal prototypes and spare parts on demand. This includes 3D printed water adapters for the Audi W12 engine manufactured on the SLM280 3D printer. Additionally, this center recently adopted Stratasys full-color, multi-material 3D printing with the J750 for its product design process.

Vote for this year’s Automotive Application of the Year in the 2019 3D Printing Awards. For the latest automotive additive manufacturing news, subscribe to our 3D printing newsletter and follow us Facebook and Twitter.

Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

Featured image shows a 3D printed auxiliary tool used on production line machinery. Photo via Audi/Sina Feirer.