Since I ran my family’s medical clinic, Centro Medico Humberto Parra, in 2007, my life has taken a very strange journey. I had no idea that I’d end up writing about 3D printing as I do today. I was so absorbed, working with the patients, staff and volunteers of our free, medical clinic, that it was hard to think about the world outside of that Bolivian rainforest. I didn’t know 3D printing existed in 2007, even though it had been around since the 80’s. In fact, I didn’t know too much about anything outside of our bubble. Now, though, I’ve been covering 3D printing news for a little over a year and I’m seeing all of these ways that the technology could be used at Centro Medico and clinics like it.

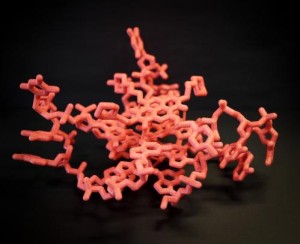

In my time writing for 3DPI, I’ve come across a lot of applications of the technology in medicine and it’s got me thinking about my old job at the clinic. Researchers at Princeton have 3D printed an ear from actual cartilage and they even went a step further and added some bionic components to make it hear better than ordinary human ears. 3D printing has made big waves in the medical field with a number of stories about the 3D printing of a variety biological tissues, such as liver cells, stem cells, even intervertebral discs. These feats promise, in the future, the ability to bring drugs to market more quickly due to the ability to test experimental medicines on artificial human tissues and, in the more distant future, the possibility of printing entire artificial organs for transplant. For a non-profit medical clinic surviving on private donations, however, these advances are probably out of reach. Instead, the more mainstream 3D printing that exists at the current moment can afford Centro Medico with some pretty phenomenal capabilities.

I haven’t yet personally come across any patients with a need for prosthetic hands or fingers, but a good deal of our patients do suffer from diabetes. Without proper control of the condition, a concurrent illness called neuropathy can occur, which leads to a loss of sensitivity in a person’s nerve endings. As a result, patients with neuropathy may not feel injuries to their feet, which can lead to an infection that spreads to the point at which a foot or toe may need to be amputated. Though Centro Medico takes pride in encouraging good foot care for diabetic patients, there are always worst case scenarios and a 3D printed toe may help someone regain balance and mobility.

Outside of direct patient treatment, 3D printing could serve various underfunded or remote medical clinics by providing lab equipment and medical models. 3D printed medical models are growing in popularity. With online repositories including more and more anatomical designs, it’s easy to 3D print models of bones, organs, and other biological features that could be used to teach patients about their own health or students eager to get into the medical field at an early age. More advanced models developed by universities may also be printed to elaborate on more complex physiological features for the clinic’s med students.

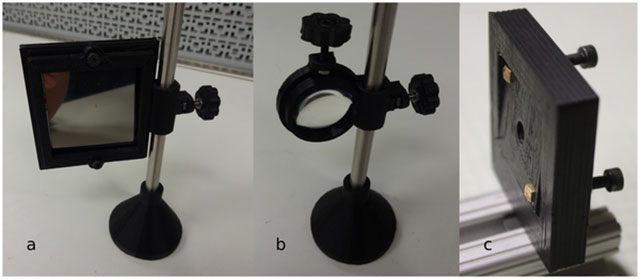

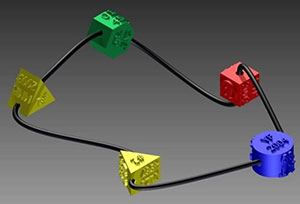

Michigan Technological University has begun creating an open library of 3D-printed components for optical devices. Mostly the library consists of plastic filters and adapters, objects that don’t rely on the glass lenses of microscopes and the like, but, as the technology and the community surrounding it grows, there will be more and more objects that are significantly cheaper than their equivalents offered by mainstream suppliers.

I could go on with the number of applications that the technology has for a clinic like ours. There are plenty more that we’ve covered at 3DPI and many more that we haven’t heard about and that no one’s thought of yet, I suspect. I don’t quite know if the technology is ready yet or if people are ready to use them to their fullest potential, but I think it may be a possibility. For that reason, I’m hoping to find a way to get one to our clinic — with the necessary support and education.

Every winter, Centro Medico Humberto Parra has an auction, in which clinic donors can bid on things like Bolivian crafts, tickets to Sox and Cubs games, and gift cards to restaurants to support our cause. At the end of the night, there’s always a raffle, where a techie prize is awarded to whoever has the winning ticket. This coming winter, I’m going to look for a generous 3D printer manufacturer to see about donating one to our clinic and one to raffle off at the auction. That way, in the US and at CMHP in Bolivia, we can see how these machines might help our small, medical community.

My hope is that, as the technology improves and is reduced in price, it may find itself in many initiatives across the planet to make the world a more liveable place. We’re still figuring out how to use 3D printing and what we might use it for. If it can be harnessed in the right ways, it’s possible that it could help clinics like Centro Medico to do a lot of good for a lot of people.