MakerBot has been receiving some flak recently regarding the patents they’ve filed for 3D printer mods. Though it hasn’t received the same negative attention as some of the others, one patent application recently uncovered by the Stratasys-owned printer manufacturer is worth noticing. In March, a patent application was filed (US20140074274 A1) by the company was published that outlined a method for 3D printing “an object larger than the build volume of a three-dimensional printer.”

When I read this, my first thought was an awesome extruding robot arm, like that of Dutch designer Joris Laarman. The actual patent describes something much less exciting and much more commonplace in the world of 3D printing. MakerBot’s patent outlines a process for 3D printing large objects by dissecting them into smaller subcomponents to be assembled upon printing. This practice is so ordinary that – this is just a wildly exaggerated guess – half of the stories on 3DPI involve it. Some that come immediately to mind are the report of a New Zealander 3D printing the frame for his Aston Martin bit by bit and the story of a yacht sailing designer 3D printing projects for his clients piece by piece.

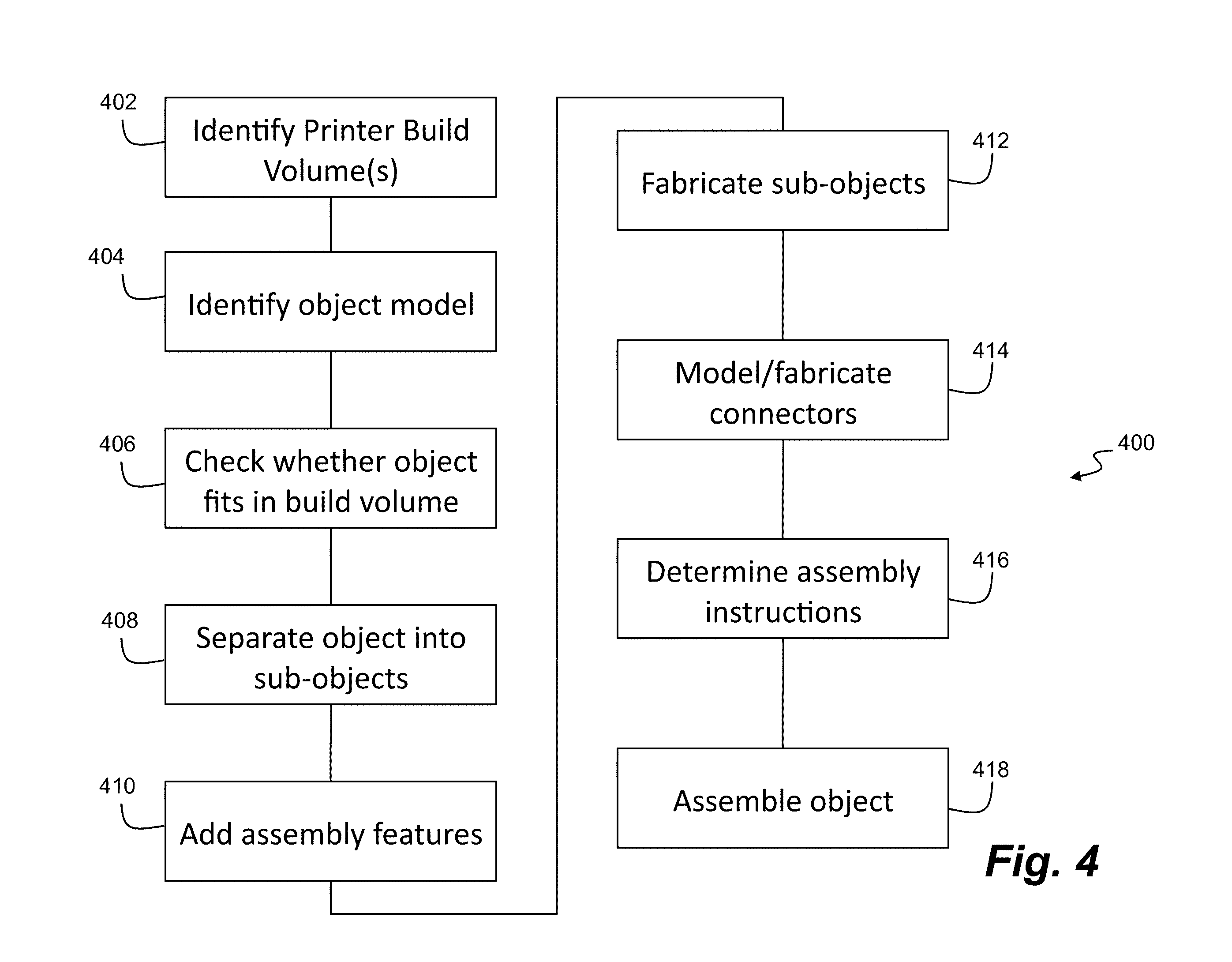

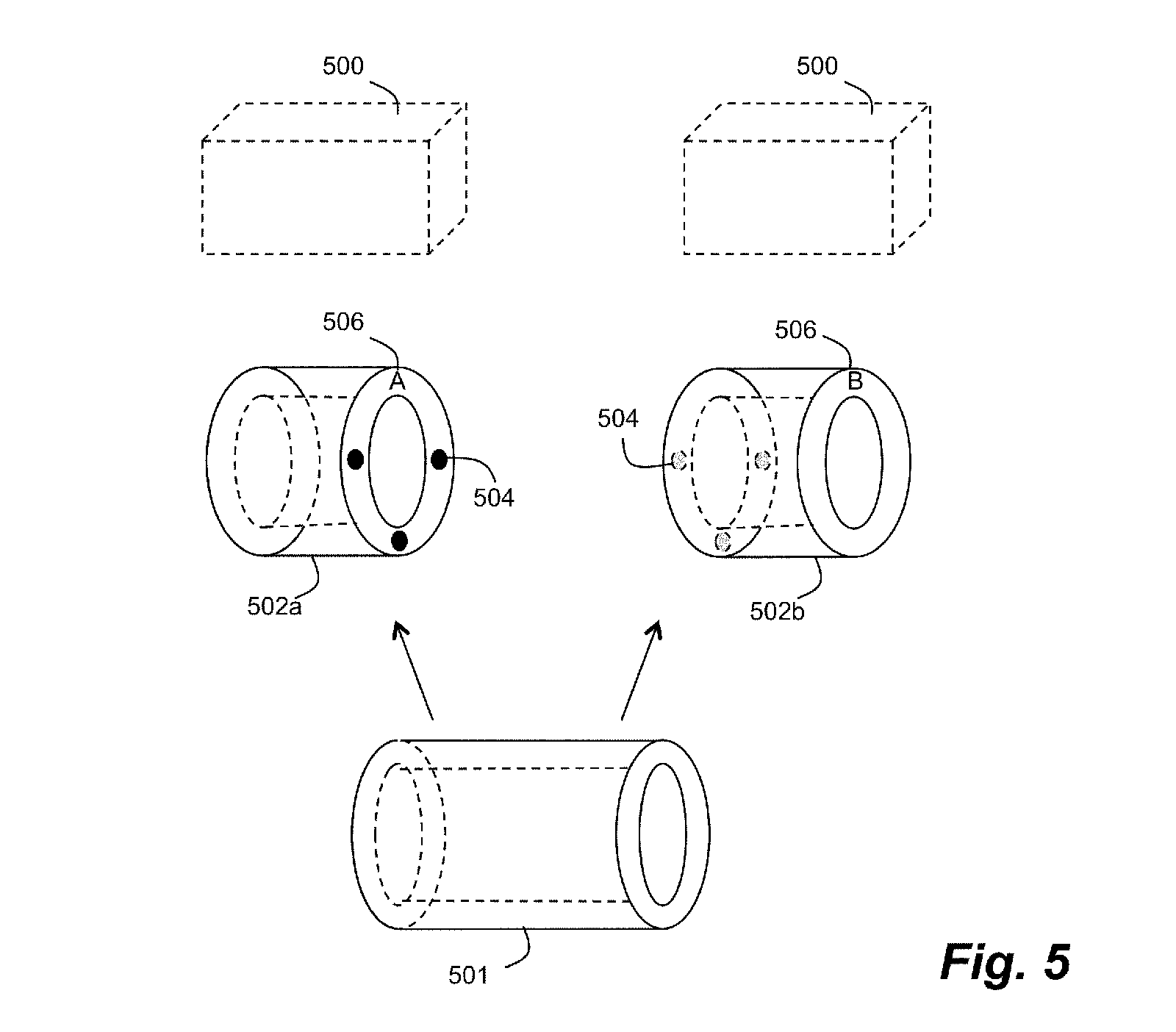

The patent does, however, add a little bit more to the process, specifically outlining methods for how to easily connect these 3D printed parts. For instance, the patent describes a method for adding holes and connectors to the subdivided 3D model, either manually or automatically using software, to join pieces after printing. The methods become increasingly interesting as the patent describes the ability to connect parts with wooden dowels, implying conceptual ties to building IKEA-like furniture; melding parts together with heat, eliminating evidence that they were ever printed separately to begin with; and incorporating sensors and cameras into the 3D printer itself, to allow for mid-print adjustments and continual feedback to make the connection of parts possible mid-print. The patent also describes the ability to print all of these sub-components serially on a single printer, or in parallel on multiple printers, possibly using software that recognizes how to best run these multiple print tasks and break a large 3D model up for these different methods.

Though some may be offended at the idea that the company would patent such a commonplace practice, it’s interesting to note the possibilities when this practice is made more complex. Incorporating 3D printed connectors into a subdivided 3D model is one thing, but melding prints and mid-print connections are a bit more advanced. As is the case with all patents, none of this means that these features will be built into a MakerBot any time soon, but that the company simply hopes to stake out intellectual claims before anyone else tries to sell the idea themselves.

Source: Google Patents

Feature Image Source: We the Builders Project, Photograph by Danielle Matich